Understanding the Benefits of Liquid Filled Pressure Gauges for Optimal Industrial Performance

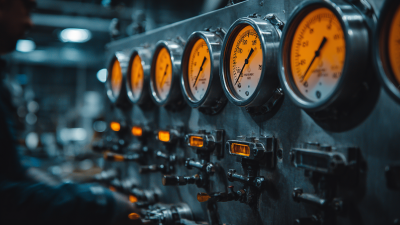

In the competitive landscape of industrial operations, maintaining optimal performance is paramount, and the role of reliable measurement tools cannot be overstated.

Liquid filled pressure gauges, specifically designed to mitigate the adverse effects of vibration and pulsation, have emerged as essential instruments in various sectors.

According to a report by Research and Markets, the global pressure gauge market is projected to grow at a CAGR of over 5% from 2021 to 2026, highlighting the increasing demand for accurate and durable measuring devices.

The benefits of liquid filled pressure gauges extend beyond mere accuracy; they enhance readability in harsh environments and provide extended service life, making them invaluable for industries such as oil and gas, pharmaceuticals, and food processing.

This blog will present a comprehensive checklist to understand why liquid filled pressure gauges are vital for achieving optimal industrial performance, ensuring that operations remain efficient and effective in today’s challenging market.

Liquid filled pressure gauges, specifically designed to mitigate the adverse effects of vibration and pulsation, have emerged as essential instruments in various sectors.

According to a report by Research and Markets, the global pressure gauge market is projected to grow at a CAGR of over 5% from 2021 to 2026, highlighting the increasing demand for accurate and durable measuring devices.

The benefits of liquid filled pressure gauges extend beyond mere accuracy; they enhance readability in harsh environments and provide extended service life, making them invaluable for industries such as oil and gas, pharmaceuticals, and food processing.

This blog will present a comprehensive checklist to understand why liquid filled pressure gauges are vital for achieving optimal industrial performance, ensuring that operations remain efficient and effective in today’s challenging market.

Exploring Different Types of Pressure Gauges and Their Applications

Pressure gauges are essential instruments in various industrial applications, providing critical data to ensure optimal performance. Among the different types available, liquid-filled pressure gauges are particularly noteworthy. According to a report by the Engineering Toolbox, liquid-filled gauges can reduce the impact of vibrations and pulsations in high-pressure environments, thereby enhancing accuracy and durability. This makes them ideal for use in industries such as oil and gas, where pressure fluctuations are common.

Pressure gauges are essential instruments in various industrial applications, providing critical data to ensure optimal performance. Among the different types available, liquid-filled pressure gauges are particularly noteworthy. According to a report by the Engineering Toolbox, liquid-filled gauges can reduce the impact of vibrations and pulsations in high-pressure environments, thereby enhancing accuracy and durability. This makes them ideal for use in industries such as oil and gas, where pressure fluctuations are common.

In addition to liquid-filled gauges, there are also Bourdon tube gauges and digital pressure gauges. Bourdon tube gauges are widely used in mechanical applications due to their reliability and simplicity. The American Society of Mechanical Engineers (ASME) states that they are capable of measuring pressures up to 10,000 psi. On the other hand, digital pressure gauges offer advanced features, such as data logging and remote monitoring capabilities. According to a study by MarketsandMarkets, the market for digital pressure gauges is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026, driven by the increasing demand for automation in industries.

Understanding the specific applications and benefits of these different types of pressure gauges can significantly enhance industrial performance. By selecting the appropriate gauge type based on operational conditions and requirements, industries can improve safety, reliability, and efficiency in their processes.

Comparative Analysis of Liquid-Filled vs. Dry Pressure Gauges

When it comes to selecting pressure gauges for industrial applications, the choice between liquid-filled and dry gauges can significantly impact performance and longevity. Liquid-filled pressure gauges utilize a damping liquid—often glycerin or silicone—to absorb vibrations and oscillations in fluctuating environments. This feature not only enhances accuracy but also prolongs the lifespan of the gauge by reducing wear and tear on internal components. In contrast, dry gauges may be more susceptible to pressure spikes and environmental factors due to their lack of this protective liquid layer.

Additionally, liquid-filled gauges provide a distinct visual advantage by preventing condensation inside the gauge, which can lead to reading errors and reduced visibility. This is particularly important in high-humidity settings where moisture can affect the performance of dry gauges. However, dry pressure gauges often perform better in extreme temperature conditions and are typically lighter, making them easier to install in various settings. By weighing these factors, industries can make informed decisions that optimize their operational efficiency while ensuring the accuracy and reliability of their pressure measurement instruments.

Understanding the Benefits of Liquid Filled Pressure Gauges for Optimal Industrial Performance

This bar chart compares the performance metrics of liquid-filled pressure gauges against dry pressure gauges across various parameters such as accuracy, sensitivity, vibration damping, temperature effects, and maintenance needs. The data illustrates that liquid-filled gauges generally provide better performance across these dimensions, highlighting their advantages in industrial applications.

The Role of Pressure Gauge Alternatives in Industrial Settings

In industrial settings, pressure gauges play a crucial role in monitoring and controlling system operations. While liquid-filled pressure gauges are widely favored for their accuracy and dampening capabilities, there are several alternative options that can also meet specific industrial needs.

These alternatives include digital pressure gauges, bimetallic gauges, and diaphragm pressure gauges, each offering unique advantages tailored to various applications.

Digital pressure gauges provide superior readability and can incorporate advanced features like data logging and remote monitoring, making them ideal for high-tech environments. Bimetallic gauges, on the other hand, are resilient to harsh conditions and offer good performance in extreme temperatures. Diaphragm gauges excel in measuring low-pressure applications, providing precise readings where traditional gauges might falter. As industries continuously evolve, understanding and exploring these alternatives allows for greater flexibility and enhanced operational efficiency in challenging environments.

Factors to Consider When Choosing Pressure Gauge Alternatives

When selecting pressure gauge alternatives, several key factors must be considered to ensure optimal industrial performance. One of the primary considerations is the environment in which the gauge will be used. For example, liquid-filled pressure gauges are ideal for applications that involve high levels of vibration or fluctuating temperatures, as the liquid dampens the movements and provides more stable readings. This makes them suitable for rugged industrial settings.

Another critical aspect to evaluate is the accuracy and range of the pressure gauge. Depending on the application, a gauge with a specific pressure range is necessary to obtain precise measurements. A gauge with a wide range may work for various applications but could compromise accuracy. Therefore, ensure that the selected gauge meets the specific requirements of your operation to avoid costly errors.

Innovations in Pressure Gauge Technology: Liquid vs. Alternatives

In the realm of industrial measurement, pressure gauges play a pivotal role, and recent innovations have highlighted the advantages of liquid-filled models over traditional alternatives. Liquid-filled pressure gauges are designed to withstand harsh environmental conditions, reducing the risk of mechanical failure due to vibration and temperature fluctuations. The viscous liquid dampens needle movement, providing a stable and accurate reading even in the most challenging settings. This feature is particularly beneficial in industries such as oil and gas, where operational reliability is critical.

Moreover, technological advancements have led to the development of specialized fluids that enhance the performance of liquid-filled gauges. These innovations not only improve the longevity of the gauge but also enhance readability under varying conditions, minimizing parallax errors and offering clearer visibility in low-light environments. Compared to dry gauges that may exhibit erratic behaviors under pressure spikes, liquid-filled options deliver precision and consistency, establishing them as the preferred choice for professionals focused on optimal industrial performance. The ongoing evolution of pressure gauge technology ensures that industries can rely on these instruments for accurate monitoring and control, ultimately boosting operational efficiency.

Understanding the Benefits of Liquid Filled Pressure Gauges for Optimal Industrial Performance

| Feature | Liquid Filled Pressure Gauges | Analog Pressure Gauges | Digital Pressure Gauges |

|---|---|---|---|

| Damping Effect | Excellent | Moderate | Low |

| Vibration Resistance | High | Moderate | Variable |

| Temperature Range | -40 to 150 °C | -20 to 120 °C | -10 to 70 °C |

| Accuracy | ± 1.5% | ± 2.5% | ± 0.5% |

| Maintenance | Low | Moderate | Low |

| Cost | Moderate | Low | High |

Related Posts

-

7 Surprising Benefits of Liquid Filled Pressure Gauges for Your Industry

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

7 Reasons Why Investing in Test Instruments Can Transform Your Quality Assurance Process

-

7 Essential Low Pressure Gauges You Need for Accurate Measurements

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

The Future of Test Instruments in Industry Innovation

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments