10 Best Instruments Gauges for Accurate Measurements in 2023

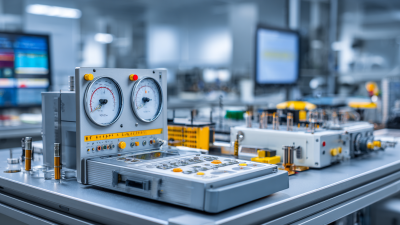

In the ever-evolving landscape of precision measurement, the role of instruments gauges has become increasingly crucial across various industries. According to a recent report by MarketsandMarkets, the global market for measurement instruments is projected to reach $73 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth underscores the demand for reliable and accurate measurement tools that can enhance operational efficiency and product quality. As industries strive for greater accuracy, selecting the right instruments gauges is paramount.

This blog will delve into the ten best instruments gauges of 2023, highlighting their features, advantages, and applications, thereby equipping professionals with the knowledge to make informed purchasing decisions in a competitive marketplace.

The Importance of Precision: Why Accurate Gauges Matter in 2023

In today's fast-paced and highly competitive environment, the importance of precision in measurements cannot be overstated. Accurate gauges play a crucial role across various industries, from manufacturing to healthcare, where even minute discrepancies can lead to significant consequences. In 2023, the push for higher precision is driven by the need for quality assurance, cost-effectiveness, and adherence to stringent regulatory standards. The ability to obtain reliable data empowers businesses to make informed decisions, reduce waste, and enhance product efficiency.

Furthermore, as technologies evolve, so does the complexity of measurement processes. Advanced instruments not only improve accuracy but also integrate seamlessly with digital systems, allowing for real-time data analysis and monitoring. This advancement supports a culture of continuous improvement, enabling organizations to identify flaws proactively and refine their operations. In essence, investing in accurate gauges is not merely a matter of compliance; it is an essential strategy for fostering innovation and maintaining a competitive edge in the ever-evolving landscape of 2023.

Top 10 Instruments Gauges: Key Features to Consider for Optimal Performance

When selecting the best instrument gauges for accurate measurements, several key features should be taken into account to ensure optimal performance. Firstly, accuracy and precision are paramount. Look for gauges that offer a high level of consistency in their measurements, indicated by their calibration and specifications. Instruments that provide a clear reading with minimal errors can save time and enhance productivity in various applications, from automotive diagnostics to industrial processes.

Another crucial aspect to consider is the durability and material of the gauges. Instruments used in demanding environments should be robust enough to withstand harsh conditions such as extreme temperatures, humidity, and mechanical vibrations. Choosing gauges made from high-quality materials not only extends their lifespan but also ensures that they maintain their accuracy over time. Additionally, the ease of readability and user-friendly features, like digital displays and ergonomic designs, can significantly improve the user experience and efficiency during measurements. These features contribute to making informed decisions quickly and reliably in any technical field.

10 Best Instruments Gauges for Accurate Measurements in 2023

| Gauge Type | Measurement Range | Accuracy | Display Type | Key Feature |

|---|---|---|---|---|

| Digital Multimeter | 0-600V AC/DC | ±0.5% | LCD | Auto-ranging |

| Pressure Gauge | 0-300 PSI | ±1% | Analog | Stainless Steel Housing |

| Temperature Gauge | -50 to 300°C | ±0.3°C | Digital | Thermocouple Sensor |

| Flow Meter | 0-100 L/min | ±1% | LCD | Battery Operated |

| Humidity Gauge | 0-100% RH | ±2% RH | Digital | Built-in Calibration |

| Voltage Meter | 0-1000V | ±0.5% | LCD | Backlight Display |

| Current Meter | 0-10A | ±1% | Digital | Hold Function |

| Universal Calibrator | Varied | ±0.01% | Touchscreen | Multi-Function |

| Laser Distance Meter | 0.05-50m | ±1.5mm | LCD | Compact Design |

Comparative Analysis: Digital vs. Analog Gauges in Industry Applications

In the realm of industrial applications, the choice between digital and analog gauges can significantly impact measurement accuracy and operational efficiency. Digital gauges, which have surged in popularity, provide real-time readings with precision levels often within 0.1% of full-scale outputs, according to a 2023 report by the International Society of Automation. This high degree of accuracy is crucial in industries like manufacturing and pharmaceuticals, where even minute variations can lead to compliance issues or operational failures.

Conversely, analog gauges still hold a strong position due to their simplicity and reliability, particularly in environments where electronic devices may be prone to failure. A study published by the American Society for Quality highlights that analog gauges are less affected by electromagnetic interference, making them suitable for use in industrial settings characterized by heavy machinery and fluctuating temperatures. According to industry data, approximately 35% of firms in manufacturing prefer analog gauges for their robustness, while 50% lean towards digital gauges for their ease of use and better readability.

Ultimately, the decision between digital and analog gauges hinges on specific application needs, including the required accuracy, environmental conditions, and user preferences. Organizations must evaluate these factors carefully to ensure optimal measurement performance in their operational processes.

Comparison of Digital and Analog Gauge Accuracy in 2023

User Reviews and Ratings: The Most Trusted Instruments Gauges of 2023

When it comes to precision in measurements, the right instrument gauge can make all the difference. In 2023, user reviews and ratings have highlighted several top contenders that stand out for their reliability and performance. Customers repeatedly praise gauges like the

Brown & Sharpe Digital Indicator

for its accuracy and ease of use, making it a preferred choice for both professionals and hobbyists alike. Its robust design paired with user-friendly features ensures it can withstand rigorous use while providing consistent results.

In another popular choice, the

Fluke 17B+ Multimeter

has garnered attention for its versatility. Users rave about its ability to measure voltage, current, and resistance with precision, making it an essential tool for electricians and engineers. The extensive customer feedback reveals a consistent trend—people appreciate instruments that not only deliver accurate readings but also prioritize durability and ease of operation. As 2023 progresses, these trusted instruments continue to receive accolades, proving that user experiences play a crucial role in determining the best tools for accurate measurements.

Innovative Technologies Shaping the Future of Measurement Instruments

Innovative technologies are significantly transforming the landscape of measurement instruments, pushing the boundaries of accuracy and efficiency. In 2023, we are witnessing a surge in the integration of smart sensors and IoT capabilities within gauges. These advancements enable real-time data collection and analysis, allowing users to make informed decisions based on accurate measurements. For instance, digital pressure gauges now come equipped with wireless connectivity, transmitting data to centralized systems where it can be monitored and acted upon without the need for manual intervention.

Another notable trend is the development of advanced materials and manufacturing techniques that enhance the durability and precision of measurement instruments. Innovative ceramics and composites are being utilized to create gauges that withstand harsh environments while maintaining accuracy over extended periods. Additionally, software advancements, such as artificial intelligence and machine learning, are being applied to interpret measurement data more effectively, identifying patterns and anomalies that may indicate underlying issues. These technologies are not just shaping the performance of instruments but are also paving the way for new applications in various industries, from aerospace to healthcare, ensuring that accurate measurements remain at the forefront of technological progress.

Related Posts

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

7 Reasons Why Investing in Test Instruments Can Transform Your Quality Assurance Process

-

Navigating the Challenges of Precision Devices in Today's High Demand Markets

-

5 Essential Tips for Choosing the Right Liquid Filled Gauges

-

The Future of Test Instruments in Industry Innovation

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments