What Are the Best Precision Instruments for Accurate Measurements?

In today's world, accurate measurements play a crucial role across various fields, from science to engineering. Precision instruments are essential tools that ensure reliability and consistency in data collection. These instruments help researchers and professionals achieve results that can be trusted. However, not all precision instruments are created equal.

Each type has its strengths and limitations. Consider the calibration process, for example. A poorly calibrated instrument can lead to significant errors. This serves as a reminder that even the best tools require regular maintenance and assessment. Furthermore, the choice of a precision instrument often depends on the specific measurement needs, requiring careful consideration of the task at hand.

When selecting precision instruments, one must reflect on their intended use and the environment in which they operate. Factors like temperature, humidity, and even operator skill can affect performance. It’s vital to recognize that achieving accurate measurements is an ongoing journey, often marked by trial and error. Emphasizing quality and attention to detail is key to success in any precision measurement endeavor.

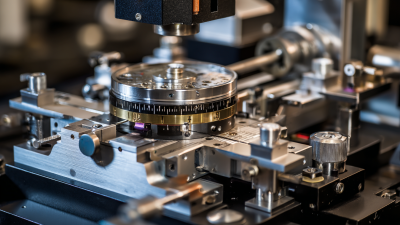

Types of Precision Instruments for Accurate Measurements

Precision instruments are crucial for accurate measurements in various fields. One of the most common types is the caliper. Calipers can measure internal and external dimensions of objects precisely. They are handy for both small and large items, offering a reliable way to ensure accuracy in mechanical work. However, improper use can lead to errors. Users must handle them carefully.

Another essential tool is the micrometer. This instrument provides highly accurate thickness measurements. It’s often used in engineering and manufacturing. A micrometer can measure with great precision, down to a thousandth of a millimeter. Yet, like calipers, novice users can make mistakes by squeezing too hard or not calibrating the tool properly.

Finally, the digital multimeter serves another purpose altogether. It is vital for electrical measurements. This instrument measures voltage, current, and resistance accurately. But it can be overwhelming for beginners. Users must understand how to switch settings correctly and read the display. Precision instruments demand careful attention and practice to ensure reliability. Without proper understanding, the chance for errors increases.

Key Features to Consider in Precision Measurement Tools

When choosing precision measurement tools, several key features stand out. Accuracy is paramount. A device should have a low margin of error. A measurement tool that consistently yields varying results requires reconsideration. Another significant feature is resolution. Tools with higher resolution can detect smaller changes. This is especially crucial in laboratory settings.

Moreover, ease of use matters. Complex instruments may lead to user errors. Clear displays and intuitive controls help enhance the user experience. Durability is also vital. Tools must withstand usage in various environments. Frequent repairs can lead to delays in projects. It's essential to find a balance between precision and practicality.

The calibration process is where many users stumble. Regular calibration ensures reliable data. Tools that are not calibrated accurately can compromise entire experiments. Calibration also demands time and resources, often overlooked. The right tools should facilitate these processes, not complicate them.

What Are the Best Precision Instruments for Accurate Measurements? - Key Features to Consider in Precision Measurement Tools

| Instrument Type | Accuracy | Measurement Range | Key Features |

|---|---|---|---|

| Caliper | ±0.02 mm | 0 - 150 mm | Digital display, fine adjustment, stainless steel |

| Micrometer | ±0.01 mm | 0 - 25 mm | Rotating thimble, screw thread, calibration standards |

| Laser Distance Meter | ±1 mm | 0.05 - 100 m | Bluetooth connectivity, area/volume calculation, backlit screen |

| Electronic Scale | ±0.01 g | 0 - 10 kg | Tare function, automatic shutdown, multiple units |

| Palletizer | ±0.1 mm | Variable size | Versatile configurations, persistent memory, safety features |

Applications of Precision Instruments in Various Industries

Precision instruments play a crucial role in various industries. In manufacturing, they ensure products meet strict specifications. For instance, micrometers and calipers gauge dimensions with remarkable accuracy. Engineers rely on these tools for tight tolerances, impacting quality control significantly.

In healthcare, precision instruments are vital for diagnostics. Blood pressure monitors must be precise for correct readings. Even slight inaccuracies can lead to misdiagnosis. Similarly, laboratory equipment like pipettes needs calibration. A small error can skew results, affecting patient care.

Environmental monitoring also uses precision instruments. Sensors measure air quality, temperature, and humidity levels. Accurate data informs policy decisions and public health initiatives. Yet, human error and instrument limitations can affect outcomes. Regular maintenance is essential to ensure reliability over time.

Top Brands Known for Quality Precision Measurement Devices

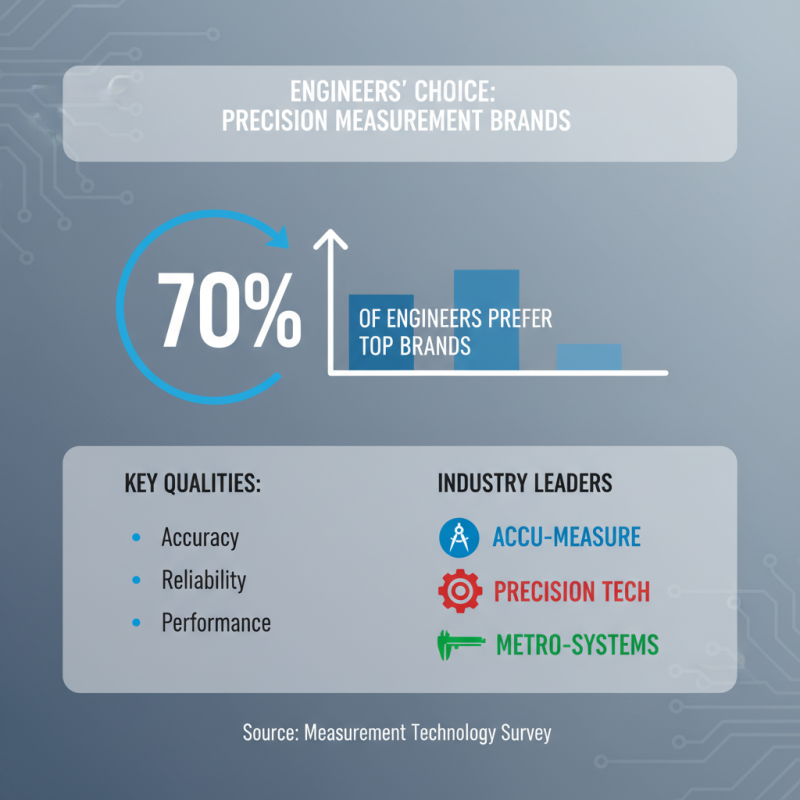

In the realm of precise measurements, several brands are recognized for their quality products. These brands have set benchmarks in accuracy and reliability. According to a recent survey by a measurement technology company, around 70% of engineers prefer devices from these top brands due to their performance.

Typically, precision instruments fall into various categories. For instance, calipers are vital in many industries. They can measure dimensions with an accuracy of up to 0.02 mm. Despite this precision, users often overlook the importance of proper calibration. Regular maintenance ensures consistent accuracy, yet many instruments go unchecked for long periods.

Additionally, gauges play a crucial role in industrial settings. A study indicates that precision gauges can enhance production efficiency by up to 30%. However, the human factor is often a bottleneck. Misinterpretation of readings can lead to errors. Training employees to understand these devices better remains a critical yet neglected aspect of operations. Precision is essential, yet the process is prone to oversight.

Maintaining and Calibrating Precision Instruments for Optimal Accuracy

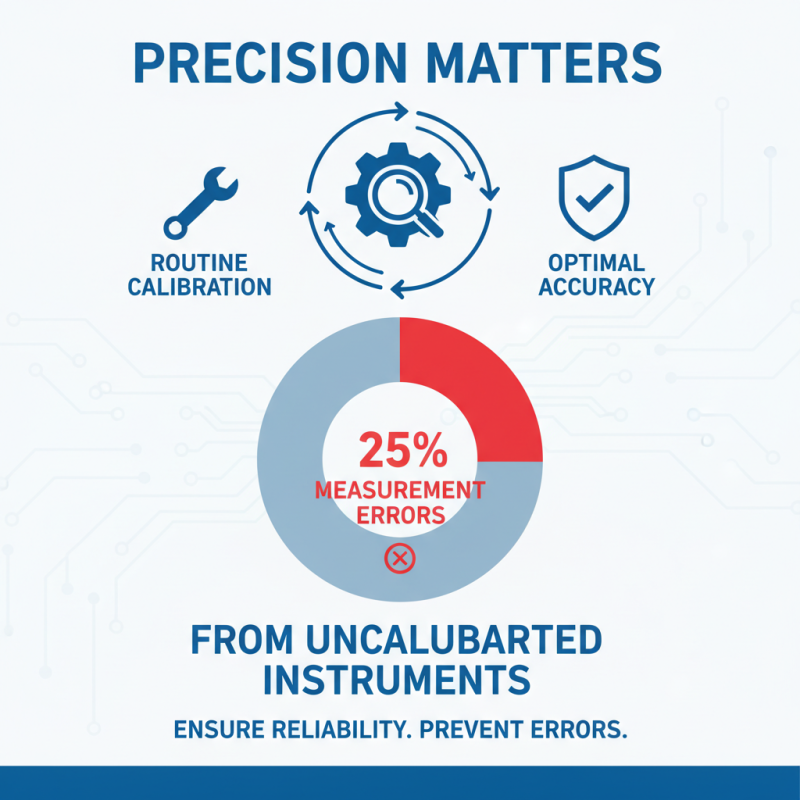

Precision instruments play a critical role in various fields. For optimal accuracy, maintaining and calibrating these tools is essential. Regular calibration ensures that measurements are within specified tolerances. An industry report indicated that nearly 25% of all measurement errors stem from uncalibrated instruments. This statistic underscores the importance of routine checks.

Calibration is not a one-time task. Instruments can drift over time due to factors like temperature and humidity. For instance, a temperature variation of just 1 degree Celsius can lead to a 2% error in certain measurement devices. The need for a consistent calibration schedule becomes evident. For many industries, a biannual calibration is recommended to uphold standards. Yet, many organizations fall short in this area.

Users should be aware of how external factors can impact accuracy. Contaminants, for instance, can affect weight scales. A misplaced decimal in measurement readings can lead to costly mistakes. Training personnel on recognizing signs of instrument drift is vital. Regular maintenance routines should be adjusted based on how frequently the instruments are used. Not all instruments calibrate in the same way, and some require more careful handling. Vigilance is key to ensuring precision.

Related Posts

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

The Future of Test Instruments in Industry Innovation

-

Ultimate Guide to Choosing the Right Precision Instruments for Your Needs

-

7 Essential Tips for Choosing Precision Instruments for Your Business Needs

-

How to Choose Precision Instruments for Optimal Measurement Accuracy: A Data-Driven Guide

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments