Essential Checklist for Choosing the Right Digital Pressure Gauges

In today's rapidly evolving industrial landscape, the choice of instrumentation such as digital pressure gauges has become paramount for ensuring operational efficiency and accuracy. According to a recent report from MarketsandMarkets, the global pressure gauge market is projected to grow from $2.9 billion in 2021 to $3.8 billion by 2026, highlighting the increasing importance of precise measurement tools.

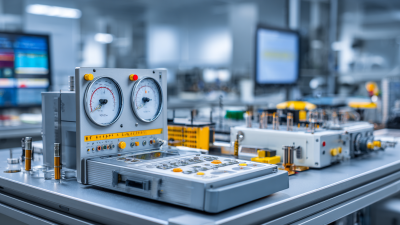

Digital pressure gauges, known for their ease of use and high accuracy, are essential in various applications ranging from manufacturing to HVAC systems. However, with numerous options available, selecting the right digital pressure gauge can be daunting. This blog will provide an essential checklist and top strategies to assist professionals in making informed decisions that enhance their operations while optimizing safety and reliability.

Key Factors to Consider When Selecting Digital Pressure Gauges

When selecting digital pressure gauges for your needs, several key factors should be taken into account to ensure optimal performance and accuracy. First and foremost, consider the gauge’s accuracy and resolution. A high degree of precision is crucial, especially in applications where minute changes in pressure can significantly impact the process. Look for gauges with a low percentage of full-scale accuracy to ensure consistent and reliable readings.

Another important factor is the operating range of the digital pressure gauge. It’s essential to choose a gauge that can accurately measure within the specific range relevant to your application. If you expect to encounter extreme pressures, ensure that the selected gauge can handle such conditions without risking damage or inaccurate readings.

**Tips:** Always verify the compatibility of the gauge materials with the substances being measured, as chemical reactions can compromise the integrity and accuracy. Additionally, consider digital features such as data logging and connection capabilities, which can enhance functionality and facilitate easier monitoring of pressure trends over time. Prioritize these factors to make an informed decision that aligns with your needs.

Essential Checklist for Choosing the Right Digital Pressure Gauges - Key Factors to Consider When Selecting Digital Pressure Gauges

| Feature | Importance | Recommended Range | Common Applications |

|---|---|---|---|

| Accuracy | High | ±0.25% of Full Scale | Industrial Monitoring, Calibration |

| Range | High | 0-1000 psi | Hydraulics, Pneumatics |

| Display Type | Medium | Digital LCD | Laboratories, Research |

| Power Source | Medium | Battery Powered / AC | Field Use, Utilities |

| Response Time | High | <1 second | Process Control |

| Environmental Rating | High | IP67 | Outdoor Applications |

Understanding Different Types of Digital Pressure Gauges Available

When selecting a digital pressure gauge, it’s vital to understand the different types available to ensure you make the best choice for your specific needs. Digital pressure gauges typically fall into three main categories: absolute, gauge, and differential pressure gauges. Absolute pressure gauges measure pressure relative to a perfect vacuum, making them ideal for sensitive applications such as barometric pressure monitoring. Gauge pressure gauges measure pressure relative to atmospheric pressure, commonly used in tire pressure monitoring and hydraulic systems. Differential pressure gauges, on the other hand, measure the difference between two pressure points, which is crucial in applications like filtration systems.

When choosing a digital pressure gauge, consider the following tips: First, assess the specific requirements of your application, such as pressure range and operating environment. Ensure the gauge is rated for the conditions it will encounter, such as temperature and humidity extremes. Additionally, focus on the display and readability—choose a gauge with a clear and easy-to-read digital display, especially if it will be used in low-light settings. Lastly, evaluate the gauge’s features, such as data logging capabilities and wireless connectivity, which can enhance usability and operational efficiency, making it easier to monitor and record pressure data accurately.

Essential Checklist for Choosing the Right Digital Pressure Gauges

Essential Features to Look for in a High-Quality Digital Pressure Gauge

When selecting a high-quality digital pressure gauge, several essential features should be at the forefront of your decision-making process. First and foremost, accuracy is critical. Look for gauges that offer high precision with minimal deviation in measurements. Many industrial applications require reliable data, so opting for a device with an accuracy rating of ±0.5% or better can significantly enhance your workflow and safety protocols.

In addition to accuracy, consider the gauge's durability and environmental resistance. Depending on your application, gauges may be exposed to extreme temperatures, moisture, or corrosive substances. A robust enclosure rating, such as IP65 or higher, ensures that the gauge can withstand harsh conditions. Furthermore, features like a shock-resistant design and high-quality materials can prolong the lifespan of the device, leading to cost savings in replacements over time. Lastly, look for easy-to-read displays and user-friendly interfaces to facilitate quick and efficient readings, especially in high-paced environments.

Common Mistakes to Avoid When Choosing Digital Pressure Gauges

When selecting digital pressure gauges, it's crucial to steer clear of common pitfalls that can lead to inefficiencies and increased costs. One of the most frequent mistakes is neglecting to assess the specific requirements of your application. Different environments and processes call for different gauge specifications, such as pressure range, accuracy, and compatibility with various fluids. Failing to align these factors can not only result in inaccurate readings but also in premature equipment failure.

Another misstep is overlooking the importance of display features. Some users opt for gauges that are difficult to read under varying light conditions or from a distance. A clear display with appropriate unit options is essential for quick and effective monitoring. Additionally, consider the interface and connectivity features; digital gauges that offer easy integration with other equipment can save valuable time and enhance overall system performance. Prioritizing these criteria can significantly improve the functionality and longevity of your pressure measurement solutions.

Tips for Maintaining and Calibrating Your Digital Pressure Gauge for Accuracy

Maintaining and calibrating your digital pressure gauge is crucial to ensure accurate measurements and optimal performance. Regular maintenance involves checking for any physical damage, leaks, or blockages in the pressure sensor and tubing. A clean gauge not only lasts longer but also provides reliable readings. It’s beneficial to schedule routine inspections based on the frequency of use and the operating environment's severity. Additionally, always keep the manufacturer's guidelines on hand for specific maintenance recommendations.

Calibrating your digital pressure gauge is another vital step in ensuring accuracy. This process involves comparing the readings of your gauge against a known standard and making necessary adjustments. It’s recommended to perform this calibration before significant uses or after extended periods of inactivity. Most gauges have a built-in calibration feature, but for others, you may need specialized tools or professional services. By ensuring that your digital pressure gauge is correctly maintained and calibrated, you can avoid costly mistakes and enhance the overall efficiency of your operations.

Related Posts

-

The Future of Test Instruments in Industry Innovation

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

7 Reasons Why Investing in Test Instruments Can Transform Your Quality Assurance Process

-

5 Essential Tips for Choosing the Right Liquid Filled Gauges

-

The Ultimate Guide to Choosing the Perfect Digital Manometer for Your Needs

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments