How to Choose the Right Pressure Gauges for Your Applications

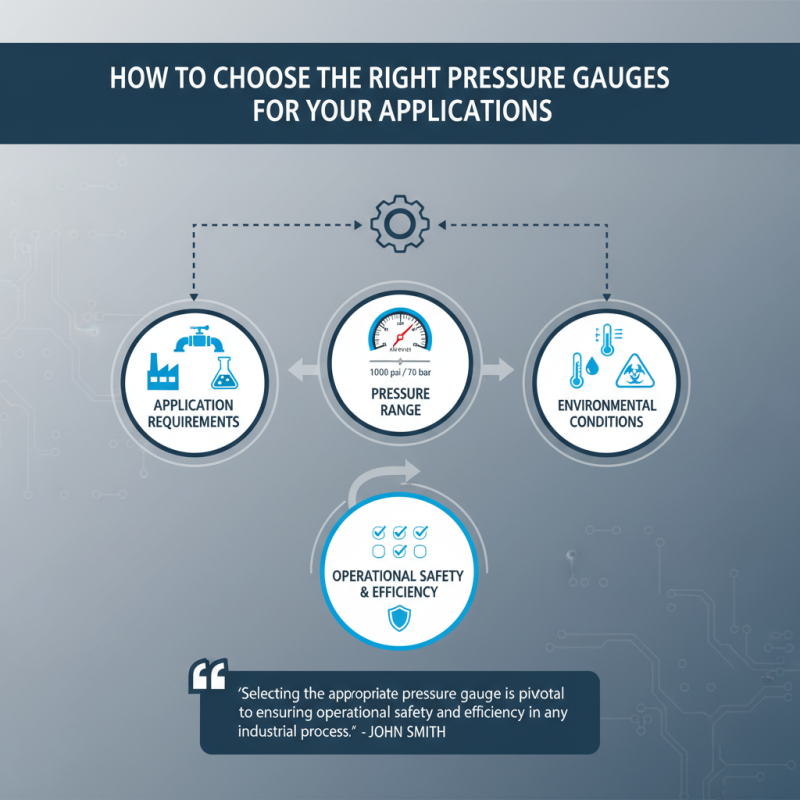

Choosing the right pressure gauges for your applications is a task that demands careful consideration and expert insight. According to John Smith, a renowned expert in the field of instrumentation, "Selecting the appropriate pressure gauge is pivotal to ensuring operational safety and efficiency in any industrial process." This statement underscores the importance of understanding the various factors that influence the choice of pressure gauges, including the specific requirements of the application, the range of pressure, and the environmental conditions under which the gauges will operate.

In today's diverse and demanding industrial landscape, pressure gauges serve as vital instruments for monitoring and controlling various processes. Their accuracy and reliability can significantly impact performance outcomes, product quality, and safety measures. However, with numerous types and specifications available, the selection process can become overwhelming. By focusing on key features and understanding the operational context, users can make informed decisions that enhance their systems' functionality. Thus, delving into what makes a pressure gauge suitable for specific applications is not merely a technical choice but a cornerstone of operational excellence in any field reliant on pressure measurement.

Understanding the Basics of Pressure Gauges and Their Functionality

Pressure gauges are essential instruments used to measure the pressure of gases or liquids within various systems. Understanding their basic functionality is crucial for selecting the right gauge for your specific application. Most pressure gauges operate on the principle of a mechanical deformation that occurs when pressure is applied. This deformation displaces a pointer on a dial, providing a visual representation of the pressure level. Some common types include analog gauges, which utilize a Bourdon tube mechanism, and digital gauges that offer electronic readings for improved accuracy and ease of use.

When choosing a pressure gauge, it is important to consider several factors such as the pressure range, accuracy, and environmental conditions. Different applications may require gauges that can withstand high pressures or extreme temperatures. Additionally, the materials used in the construction of the gauge can impact its durability and compatibility with the fluids being measured. For instance, corrosive fluids may require gauges made from specific materials to prevent damage. By understanding these basics, users can make informed decisions to select the most suitable pressure gauge for their needs.

Types of Pressure Gauges: Selecting the Right Type for Your Needs

When selecting the right type of pressure gauge for your application, it's crucial to understand the various types available and their specific use cases. Common pressure gauges include analog gauges, digital gauges, and compound gauges. Analog gauges, often favored for their simplicity and cost-effectiveness, provide a direct visual representation of pressure readings. According to a report by the Pressure Measurement Association, approximately 60% of industrial applications still utilize analog gauges due to their reliability and ease of maintenance.

On the other hand, digital gauges have gained popularity for their accuracy and additional functionality, such as data logging and remote monitoring capabilities. A recent survey by the International Society of Automation indicated that digital gauges are increasingly preferred in sectors requiring precise pressure management, such as pharmaceuticals and aerospace. Furthermore, compound gauges, which measure both positive and negative pressures, are essential in applications involving vacuums and may see a rise in demand as industries expand their automation processes.

Understanding the operational environment is also key to selecting the right pressure gauge type. For example, gauges used in high-temperature or corrosive environments must be specifically designed to withstand these conditions. The report from the Measurement Science Conference underscores that over 30% of gauge failures occur due to environmental factors, highlighting the need for careful selection based on these criteria. By considering the unique requirements of your application and the characteristics of each gauge type, you can ensure optimal performance and reliability.

Pressure Gauge Selection Overview

Key Factors to Consider When Choosing Pressure Gauges

When selecting the right pressure gauges for your applications, there are several key factors to consider to ensure optimal performance and reliability. First and foremost, one must assess the range and accuracy required for the specific application. According to industry data from the International Society of Automation, choosing a gauge with a range that exceeds the maximum pressure of the system by no more than 50% can help maintain accuracy while extending the lifespan of the gauge. Typically, gauges exhibiting an accuracy of ±1% of full scale are advisable for most industrial applications, as they provide a good balance between precision and affordability.

Additionally, the environment in which the gauge will operate plays a critical role in its selection. Factors such as temperature, humidity, and exposure to corrosive substances must be taken into account. A study by the Pressure Relief Device Manufacturers Association highlights that selecting materials compatible with the process fluid significantly reduces the risk of damage and ensures long-term reliability. For instance, stainless steel diaphragms are favorable in corrosive environments, whereas plastic gauges may suffice for non-corrosive, low-pressure applications.

Lastly, consider the gauge's installation compatibility and ease of maintenance. The ability to easily install and calibrate the gauge can greatly influence operational efficiency. Research from the American National Standards Institute indicates that gauges designed for easy field adjustments can minimize downtime during maintenance, making them a preferred choice in industries where continuous monitoring is crucial, such as oil and gas. Taking these factors into account can enhance the effectiveness of pressure monitoring in your specific application, leading to improved process safety and efficiency.

Understanding Accuracy and Range Specifications for Pressure Gauges

When selecting the right pressure gauge for your applications, understanding accuracy and range specifications is crucial. Accuracy refers to how close the gauge reading is to the actual pressure measurement. Gauges come in various grades of accuracy, typically expressed as a percentage of the full scale. For instance, a gauge with 1% accuracy will have a maximum deviation of 1 unit at its full scale. If your application requires precise measurements, choosing a gauge with a higher accuracy rating is essential to ensure reliable performance.

The range specification defines the minimum and maximum pressure levels a gauge can measure, and it's vital to select one that fits your application’s operational parameters. A gauge that operates near the lower end of its range may exhibit non-linear behavior, leading to inaccurate readings. Therefore, it's beneficial to choose a gauge that covers the expected pressure range while also providing a buffer for potential fluctuations.

Tips: Always consider the operating environment when selecting a pressure gauge. Factors such as temperature, humidity, and potential exposure to chemicals can affect gauge performance. Furthermore, regularly calibrating the gauge can help maintain its accuracy over time, ensuring consistent and reliable readings in your applications.

Maintaining and Calibrating Pressure Gauges for Longevity and Accuracy

Maintaining and calibrating pressure gauges is crucial for ensuring their longevity and accuracy in any application. Regular calibration not only helps to uphold safety standards but also enhances the reliability of measurement data. According to the National Institute of Standards and Technology (NIST), a properly calibrated pressure gauge can minimize measurement uncertainty to less than 0.1%, enabling operators to make more informed decisions based on precise readings.

To maintain the integrity of your pressure gauges, it is advisable to develop a routine maintenance schedule. This should include regular inspections for signs of wear, corrosion, or leaks, as these issues can directly affect performance. Environmental factors, such as temperature fluctuations and exposure to moisture, can also impact gauge functionality. As a best practice, facilities should document these checks and any calibration adjustments made, helping to trace any deviations in performance over time.

**Tips for Maintenance:**

- Inspect gauges visually every few months to catch any physical damage early.

- Utilize certified calibration services at least once a year to ensure consistent accuracy.

- Store gauges in a controlled environment to protect against dust and moisture.

By prioritizing maintenance and calibration, you'll not only extend the lifespan of your pressure gauges but also achieve optimal operational efficiency in your applications. Regular attention to these practices allows for better risk management and adherence to safety regulations.

How to Choose the Right Pressure Gauges for Your Applications - Maintaining and Calibrating Pressure Gauges for Longevity and Accuracy

| Application | Gauge Type | Pressure Range (psi) | Material | Calibration Frequency | Notes |

|---|---|---|---|---|---|

| Hydraulic Systems | Digital Pressure Gauge | 0-5000 | Stainless Steel | 6 months | High accuracy required |

| Food Processing | Bourdon Tube Gauge | 0-100 | Copper Alloy | 12 months | Must meet hygiene standards |

| Chemical Industry | Diaphragm Gauge | 0-300 | PTFE-coated | 3 months | Corrosive materials |

| HVAC Systems | Analog Pressure Gauge | 0-30 | Brass | 12 months | Standard monitoring |

| Water Treatment | Submersible Gauge | 0-60 | PVC | 6 months | For submerged use |

Related Posts

-

7 Essential Low Pressure Gauges You Need for Accurate Measurements

-

7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

-

Understanding the Importance of Low Pressure Gauges in Industrial Applications

-

The Essential Guide to Understanding Pressure Gauges: Applications, Types, and Maintenance Tips

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

Understanding Pressure Gauges for Water: Key Metrics and Their Importance in Fluid Management

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments