Digital Best Practices for Measuring Differential Pressure Effectively

Effective measurement of differential pressure is crucial in various industrial applications, particularly in maintaining system efficiency and safety. Differential pressure refers to the difference in pressure between two points within a system, and its accurate monitoring can provide vital information about flow rates, filtration effectiveness, and leak detection, among other operational parameters. With the increasing complexity of modern systems, adopting digital best practices becomes essential for achieving precise and reliable measurements.

Utilizing advanced digital tools and methodologies can significantly enhance the ability to measure differential pressure accurately. These innovations not only streamline the measurement process but also improve the data quality, allowing for better analysis and decision-making. The integration of real-time monitoring systems, data analytics, and automated calibration techniques can lead to more efficient operations and reduced downtime. As industries continue to prioritize safety and efficiency, implementing these digital best practices will ensure that differential pressure measurements are both effective and dependable.

In conclusion, the effective measurement of differential pressure is integral to optimizing industrial processes. By harnessing digital technologies and best practices, organizations can achieve greater accuracy in their data collection and analysis efforts, ultimately leading to improved performance and operational excellence. Embracing these methodologies will empower industries to navigate the complexities of modern systems while ensuring safety and reliability.

Understanding Differential Pressure: Concepts and Importance

Differential pressure is a fundamental concept in various fields, including fluid mechanics, HVAC systems, and industrial processes. It refers to the difference in pressure between two points within a system, which can serve as a crucial indicator of operational efficiency, safety, and performance. Understanding differential pressure is essential for maintaining the optimal functionality of equipment, as deviations from expected pressure differentials can signal issues like blockages, leaks, or faults in machinery.

The importance of accurately measuring differential pressure cannot be overstated. It plays a vital role in applications such as filter monitoring, where a significant change in pressure can indicate when maintenance is needed. Additionally, in HVAC systems, differential pressure measurements can help ensure proper airflow and energy efficiency, ultimately leading to reduced operational costs. Understanding the concepts surrounding differential pressure allows engineers and technicians to interpret data effectively, make informed decisions, and implement timely interventions to avoid costly downtime or system failures. Hence, mastering differential pressure measurement techniques is not only beneficial but also crucial for operational excellence across various industries.

Key Equipment and Sensors for Measuring Differential Pressure

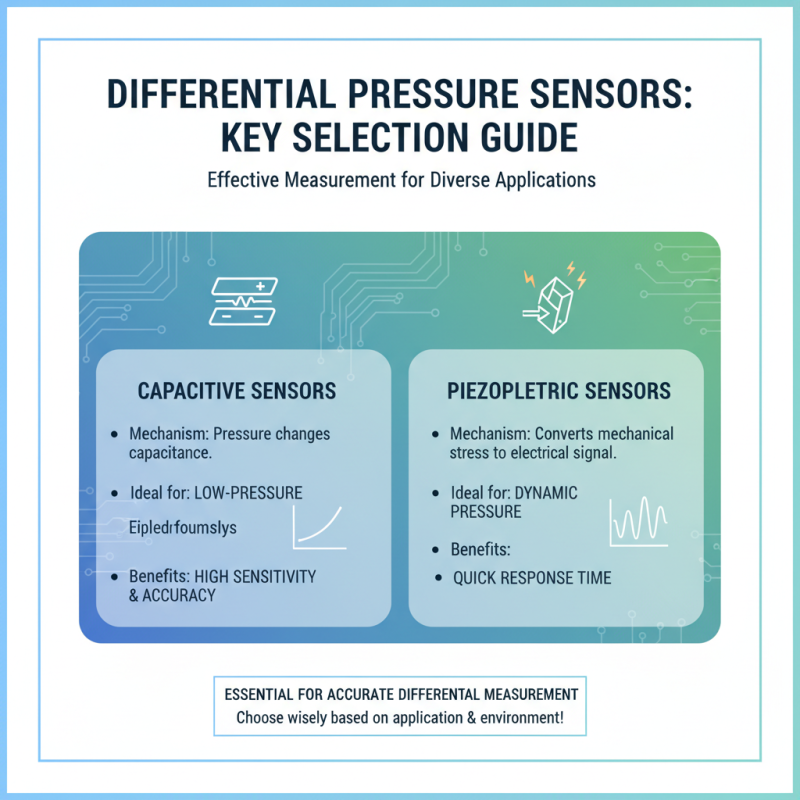

When it comes to measuring differential pressure effectively, selecting the right key equipment and sensors is essential. Various types of differential pressure sensors are available, each suited for different applications and environments. For instance, capacitive and piezoelectric sensors are popular due to their high sensitivity and accuracy. Capacitive sensors rely on changes in capacitance produced by the pressure difference, making them ideal for low-pressure applications. On the other hand, piezoelectric sensors operate by converting mechanical stress into an electrical signal, which provides quick response times and is beneficial in dynamic pressure conditions.

Another critical equipment category includes manometers and differential pressure gauges, which provide a visual indication of pressure differences. These traditional tools, although analog, are still relevant in many sectors, especially for simple applications where digital solutions may be unnecessary. Additionally, electronic diffential pressure transmitters offer advanced features such as digital readouts, remote monitoring capabilities, and integration with control systems, enhancing precision and operational efficiency. When deploying these sensors and equipment, it is crucial to consider factors such as the environment, expected pressure range, and the level of accuracy required, ensuring that the chosen devices will deliver reliable and effective measurements for the intended application.

Digital Technologies: Enhancing Precision in Differential Pressure Measurement

In the rapidly evolving landscape of industrial measurement, digital technologies are revolutionizing the way differential pressure is measured. Traditional methods, often reliant on mechanical sensors, can lead to inaccuracies and maintenance challenges. However, modern digital solutions leverage high-resolution sensors and advanced algorithms to enhance measurement precision. According to a recent industry report by the International Society for Measurement and Control, organizations that adopt digital measurement technologies report up to a 30% increase in measurement accuracy compared to their mechanical counterparts.

Tip: When implementing digital differential pressure measurement systems, ensure that the sensors used have appropriate calibration certificates and meet the required industry standards for accuracy. This step significantly reduces the potential for errors and enhances reliability in critical applications.

Moreover, the integration of IoT (Internet of Things) capabilities allows for real-time data monitoring and analytics. This not only streamlines operations but also provides actionable insights for predictive maintenance. A report by the Global Measurement and Automation Journal highlights that companies utilizing IoT for pressure measurement can experience a decrease in downtime by as much as 25%.

Tip: Invest in training for staff to proficiently utilize the digital tools and systems in place. This will foster a culture of continuous improvement and ensure that your team is well-equipped to harness the full potential of digital technologies for precise differential pressure measurement.

Digital Best Practices for Measuring Differential Pressure Effectively

| Parameter | Best Practice | Measurement Technology | Precision Level | Frequency of Calibration |

|---|---|---|---|---|

| Differential Pressure | Real-Time Monitoring | Digital Sensors | ±0.01 Pa | Monthly |

| Flow Rate | Data Logging | Ultrasonic Flow Meters | ±0.5% | Quarterly |

| Environmental Conditions | Environmental Monitoring | Wireless Sensors | ±1°C | Bi-annual |

| System Stability | Regular Maintenance | Pressure Transducers | ±0.02% FS | Yearly |

Best Practices for Calibration and Maintenance of Pressure Sensors

Calibrating and maintaining pressure sensors is crucial for ensuring accurate differential pressure measurements. Regular calibration is essential to verify that sensors provide precise readings over time. It is recommended to follow the manufacturer's guidelines for calibration frequency, which may be influenced by environmental conditions and the critical nature of the application. Establishing a routine calibration schedule helps in identifying drift in sensor performance early on, allowing for timely adjustments and minimizing the risk of erroneous data.

In addition to calibration, proper maintenance of pressure sensors significantly contributes to their longevity and reliability. Regular inspection should be performed to check for physical damage or signs of wear, such as corrosion or leaks, which can compromise sensor integrity. Keeping the sensor and its housing clean from debris, dust, and contaminants is also vital, as these factors can affect measurement accuracy. Furthermore, understanding the operating environment—such as humidity, temperature, and pressure ranges—is essential to select appropriate materials and protective measures for the sensors, thereby enhancing their performance and durability over time.

Data Interpretation: Analyzing Differential Pressure Measurements Effectively

Understanding differential pressure measurements is crucial for accurately interpreting data in various industrial applications. Differential pressure (DP) is the difference in pressure between two points and can provide valuable insights into system performance, flow rates, and equipment health. To analyze these measurements effectively, it’s essential to employ a systematic approach that combines theoretical knowledge with practical techniques.

Tip: Regular calibration of pressure sensors is fundamental for reliable measurements. A well-calibrated sensor ensures that the data reflects the true conditions of the system, reducing the chances of misinterpretation due to faulty readings. Implement a routine maintenance schedule to check and calibrate your equipment.

When analyzing DP data, look for trends over time rather than relying solely on isolated readings. This approach allows for the identification of patterns that may indicate underlying issues, such as blockages or leaks. Employ data visualization tools to represent this information graphically, making it easier to spot anomalies and understand the system's behavior.

Tip: Establish baseline measurements during normal operating conditions. This baseline will serve as a reference for future analyses, helping to quickly identify deviations that might necessitate further investigation or corrective actions.

Related Posts

-

Understanding Differential Pressure: Key Concepts and Applications Explained

-

How to Choose Differential Pressure Gauges for Optimal Performance in Industrial Applications

-

7 Essential Tips for Choosing the Best Refrigeration Gauges for Your Needs

-

Understanding Differential Pressure: Key Measurements Driving Efficiency in HVAC Systems

-

7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

-

2025 How to Choose the Best Refrigeration Gauges for Your Needs

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments