What are Digital Gauges for HVAC and How Do They Improve Efficiency

In the ever-evolving world of HVAC (Heating, Ventilation, and Air Conditioning) technology, digital gauges for HVAC have emerged as indispensable tools for enhancing system efficiency and accuracy. According to industry expert Dr. Emily Carter, a seasoned engineer in HVAC technologies, "The integration of digital gauges in HVAC systems signifies a crucial shift towards precision and energy management." As the demand for energy efficiency increases, these digital instruments play a vital role in monitoring and optimizing system performance.

Digital gauges for HVAC offer numerous advantages over traditional analog counterparts, providing real-time data and precise measurements that are essential for effective system diagnostics and maintenance. With features like wireless connectivity and data logging, they empower technicians to make informed decisions swiftly, ultimately leading to reduced energy consumption and enhanced system longevity. As Dr. Carter emphasizes, embracing digital technologies in HVAC not only streamlines operations but also contributes significantly to sustainability efforts in the industry.

In summary, the adoption of digital gauges for HVAC stands as a testament to the industry's commitment to innovation and efficiency, transforming how professionals manage and maintain heating and cooling systems. The shift towards these digital solutions is not just a trend; it represents a fundamental change in ensuring optimal performance in HVAC operations.

Overview of Digital Gauges in HVAC Systems

Digital gauges have become integral components in modern HVAC (Heating, Ventilation, and Air Conditioning) systems, offering precise measurements that enhance overall system performance. Unlike traditional analog gauges, digital gauges provide real-time data regarding temperature, pressure, and airflow, which allows technicians to quickly assess system conditions. The clarity and accuracy of digital readings help in diagnosing issues more effectively, reducing downtime and improving maintenance processes.

One of the significant advantages of digital gauges is their ability to store and analyze data over time. This functionality allows HVAC professionals to monitor system performance trends and make informed decisions regarding system adjustments or upgrades. Furthermore, many digital gauges include features such as alerts for high or low readings, enabling proactive measures to prevent major system failures. Overall, the implementation of digital gauges not only streamlines the troubleshooting process but also promotes energy efficiency, leading to lower operational costs and enhanced comfort in controlled environments.

Key Features of Digital Gauges for HVAC Applications

Digital gauges for HVAC applications are essential tools that help technicians and engineers monitor and measure various parameters such as temperature, pressure, and humidity. Their primary advantage lies in their accuracy and ease of use, which can significantly enhance system performance and efficiency. These gauges often feature high-resolution displays that provide real-time readings, allowing for quick assessments and adjustments.

One of the key features of digital gauges is their ability to log data over time. This function helps in identifying trends and potential issues before they escalate, ensuring proactive maintenance. Additionally, many digital gauges come equipped with Bluetooth or Wi-Fi capabilities, enabling remote monitoring and control via mobile devices. This convenience leads to faster response times and minimizes downtime in HVAC systems, ultimately improving overall operational efficiency.

**Tips:** When using digital gauges, ensure proper calibration to maintain accuracy. Regularly check battery levels if your gauge is battery-operated to avoid interruptions during critical measurements. Also, familiarize yourself with the specific features of your gauge, such as data logging and connectivity options, to fully leverage its capabilities in optimizing HVAC performance.

Digital Gauges for HVAC Efficiency Improvement

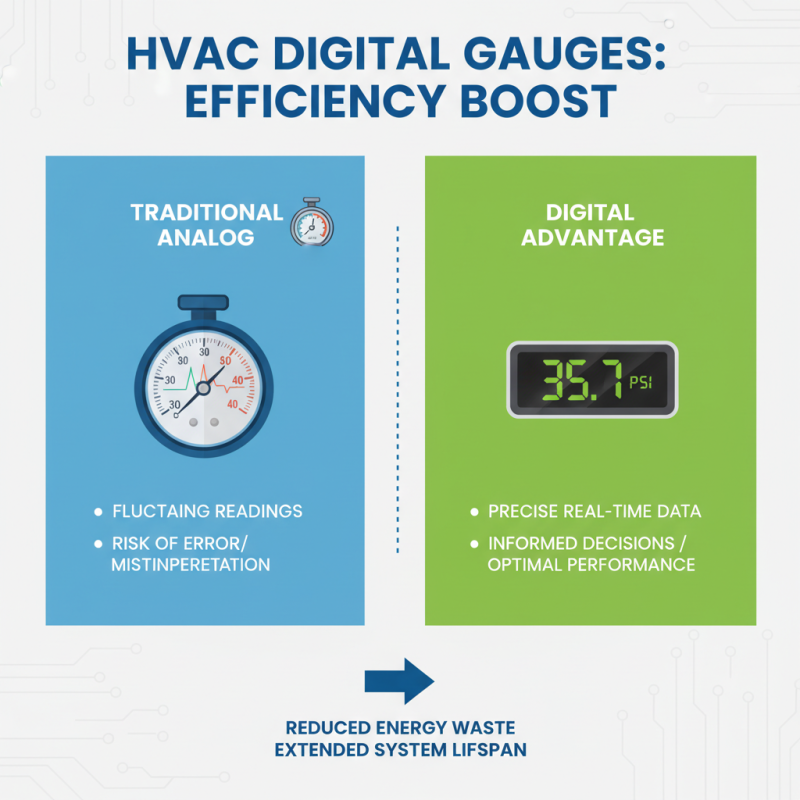

This chart illustrates the impact of using digital gauges on HVAC system efficiency across different parameters. The data shows the percentage improvement in efficiency for various aspects measured by digital gauges.

Benefits of Using Digital Gauges to Enhance Efficiency

Digital gauges represent a significant advancement in the HVAC industry, offering precise measurements and real-time data that can dramatically enhance system efficiency. One of the primary benefits of using digital gauges is their ability to provide accurate readings, which is crucial for maintaining optimal performance. Traditional analog gauges can suffer from fluctuating readings and user misinterpretation, leading to potential errors in maintenance and repairs. In contrast, digital gauges display clear numerical values, allowing technicians to quickly assess system conditions and make informed decisions that can prevent energy waste and system malfunctions.

Another key advantage of digital gauges is their integration with modern technology, which often includes data logging and communication capabilities. This functionality enables HVAC professionals to monitor systems remotely and analyze historical data trends. By identifying patterns in system performance, technicians can implement proactive maintenance schedules and address issues before they escalate. This not only enhances operational efficiency but also contributes to a longer lifespan for HVAC equipment, minimizing costs associated with repairs and replacements. Ultimately, the shift to digital gauges empowers HVAC professionals to optimize their services effectively, fostering enhanced efficiency across various applications.

Comparative Analysis: Digital Gauges vs. Traditional Gauges

Digital gauges have transformed the HVAC industry, offering enhanced precision and ease of use compared to traditional mechanical gauges. A comparative analysis reveals that digital gauges can improve efficiency by providing real-time data, which is essential for monitoring system performance accurately. According to a recent report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), HVAC systems equipped with digital gauges can improve energy efficiency by up to 20%. This improvement is primarily due to the accurate readings that allow for better system adjustments, reducing energy consumption and operational costs.

In contrast, traditional gauges often suffer from issues related to accuracy and response time. Mechanical gauges can be affected by physical wear and environmental conditions, leading to potential errors in pressure readings. Research from the Institute of Heating and Air Conditioning Engineers indicates that traditional gauges can have an accuracy deviation of up to 5%, which can significantly impact system performance. Digital gauges, on the other hand, typically boast higher accuracy levels, often within 1%, allowing for more reliable performance assessments and faster troubleshooting.

**Tips:** When transitioning to digital gauges, ensure that your team is trained to understand the new technologies for optimal use. Additionally, regularly calibrate the digital gauges to maintain high accuracy. Incorporating these practices will lead to sustained improvements in HVAC efficiency and longevity, ultimately benefiting your bottom line.

Best Practices for Implementing Digital Gauges in HVAC Systems

Implementing digital gauges in HVAC systems can significantly enhance operational efficiency, but it is essential to follow best practices to maximize their benefits. First, proper installation is crucial. Ensure that the digital gauges are calibrated correctly and positioned in optimal locations to capture accurate data. This allows for real-time monitoring of pressure, temperature, and other vital metrics. Additionally, training staff to understand the readings and interpret the data effectively can lead to more informed decision-making concerning system performance and maintenance needs.

Another best practice involves integrating digital gauges with a centralized monitoring system. This approach allows technicians to analyze data trends over time, identifying potential issues before they escalate into major problems. Regular maintenance routines should be established, emphasizing the importance of checking the gauges for accuracy. Lastly, leveraging data analytics tools can help optimize energy usage based on the insights gathered from the digital gauges, leading to potential cost savings and improved system longevity. By following these guidelines, HVAC professionals can ensure that digital gauges contribute effectively to enhancing overall system efficiency.

What are Digital Gauges for HVAC and How Do They Improve Efficiency

| Parameter | Traditional Gauges | Digital Gauges | Efficiency Improvement |

|---|---|---|---|

| Accuracy | ±2% of Full Scale | ±0.5% of Full Scale | Higher precision measurements lead to better system performance |

| Readability | Analog dials | Digital display | Easier interpretation of data |

| Data Logging | None | Built-in data logging capabilities | Enables historical analysis for better decision-making |

| Connection Options | Manual readings only | Remote monitoring capabilities | Facilitates real-time monitoring and management |

| Calibration | Manual calibration | Automatic calibration features | Reduces downtime and maintenance efforts |

Related Posts

-

Top Strategies for Utilizing Digital Gauges in HVAC Efficiency

-

What Are Digital Gauges and How Do They Revolutionize Modern Measurement?

-

Exploring the Future of Digital Gauges at the 138th Canton Fair in 2025

-

10 Essential Tips for Choosing the Right Digital Gauges for Your Needs

-

How to Optimize Your Pulp and Paper Processes for Maximum Efficiency

-

7 Essential Tips for Choosing Precision Instruments for Your Business Needs

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments