Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

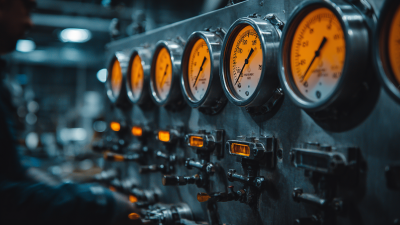

In the rapidly evolving HVAC industry, efficiency remains paramount, and one of the most crucial tools in achieving this is the use of AC gauges. According to a recent report by the U.S. Department of Energy, optimizing HVAC systems can lead to energy savings of up to 30%, significantly impacting operational costs and environmental sustainability. AC gauges play a vital role in this process, enabling technicians to monitor system performance, diagnose issues with precision, and ensure systems operate within recommended pressure ranges. With technology advancements, the integration of digital AC gauges has further enhanced accuracy and efficiency, allowing for quick data analysis. In this blog, we will explore top strategies for leveraging AC gauges effectively, underscoring the reasons why they are indispensable for HVAC professionals striving to improve service delivery and operational efficiency.

Key Metrics: Understanding the Impact of AC Gauges on HVAC System Efficiency

In the HVAC industry, understanding the impact of AC gauges on system efficiency is crucial for optimizing performance and enhancing energy savings. AC gauges, including pressure and temperature measurement tools, provide vital data that aids technicians in diagnosing issues and ensuring systems operate within optimal parameters. By accurately reading refrigerant pressures and temperatures, HVAC professionals can identify inefficiencies such as low refrigerant levels or improper airflow, which can lead to increased energy consumption and higher operational costs.

Key metrics derived from AC gauge readings allow for more informed decision-making. For instance, the superheat and subcooling measurements offer insight into the system's actual refrigerant flow, further highlighting areas where adjustments are necessary. Monitoring these metrics helps in maintaining the ideal balance between cooling output and energy use, ultimately extending the lifespan of the equipment. Regular training on interpreting these metrics effectively empowers HVAC technicians to act promptly, enhancing overall system efficiency and driving down service costs for both providers and customers.

5 Essential Features of Modern AC Gauges That Improve Workflow Efficiency

In the competitive landscape of the HVAC industry, leveraging modern AC gauges equipped with advanced features can significantly enhance workflow efficiency. According to a recent report from the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), HVAC technicians who use digital gauges can complete service calls up to 30% faster than those relying on traditional analog gauges. This improvement is largely due to the streamlined data collection and real-time analytics provided by contemporary gauge technology.

Five essential features of modern AC gauges are instrumental in driving this efficiency. Firstly, wireless connectivity allows technicians to connect to smartphones or tablets, facilitating remote monitoring and easier data sharing. Secondly, built-in leak detectors can identify issues swiftly, reducing the time spent on diagnostics. Thirdly, advanced temperature and pressure measurements provide precise readings that prevent costly mistakes. Fourthly, customizable pressure charts enable quick access to relevant data specific to a job, enhancing decision-making speed. Finally, durability and resistance to environmental factors ensure that these tools can withstand the rigors of fieldwork, ultimately leading to lower replacement costs and less downtime.

Investing in AC gauges with these features not only boosts productivity but also improves the overall service quality in the HVAC sector.

10% Time Savings: How Accurate Measurement Enhances Service Speed in HVAC

Accurate measurement is crucial in the HVAC industry, especially when it comes to using AC gauges for service and maintenance. A mere 10% time savings can significantly enhance service speed, which translates into better customer satisfaction and increased productivity. By utilizing precise AC gauges, technicians can quickly diagnose issues, ensuring that the right adjustments are made without unnecessary trial and error. This precision allows for faster repairs and installations, ultimately reducing downtime and operational costs for both service providers and clients.

Moreover, the incorporation of advanced technology in AC gauge design has made it easier for professionals to achieve accurate measurements. Features such as digital displays and smart functionalities streamline the process, allowing technicians to capture and interpret data rapidly. With the ability to pinpoint problems more efficiently, HVAC services can operate at a higher level, minimizing delays and maximizing output. This efficiency not only benefits the technicians but also enhances the overall performance of HVAC systems, leading to better energy savings and longer equipment lifespan.

Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

Efficient measurement is critical in the HVAC industry. The graph above illustrates the time taken on average using different types of gauges. The data shows that digital and smart gauges significantly reduce service time compared to manual measurement, highlighting the value of accurate tools in enhancing operational efficiency.

Top Industry Practices for Utilizing AC Gauges to Reduce Energy Costs by 15%

In the HVAC industry, effectively utilizing AC gauges is crucial for reducing energy costs. By adopting structured approaches, companies can achieve up to a 15% reduction in energy expenses. Key to this process is regular calibration of AC gauges, which ensures accurate measurements and optimal performance. This practice not only improves system efficiency but also extends the lifespan of HVAC equipment, resulting in significant cost savings over time.

Another effective strategy is implementing data analytics to monitor and analyze system performance. By tracking usage patterns and identifying inefficiencies, HVAC managers can make informed decisions about maintenance and upgrades. Additionally, fostering a culture of continuous improvement within teams ensures that best practices around gauge usage are shared and adopted widely.

Lastly, training staff on the importance of proper gauge handling and installation can dramatically impact energy consumption. Providing workshops and resources to reinforce these skills will empower technicians to operate systems at peak efficiency, translating into lower energy costs and enhanced overall productivity.

The Role of Calibration in Maintaining Precision and Efficiency in HVAC Systems

Calibration plays a pivotal role in maintaining precision and efficiency in HVAC systems, especially when utilizing AC gauges. Accurate measurement is crucial for diagnosing system performance and ensuring optimal operation. When gauges are not properly calibrated, even the slightest deviation can lead to significant errors in pressure readings, which may result in inefficient system performance, increased energy consumption, and even equipment damage. Regular calibration ensures that HVAC professionals can rely on their gauges to provide trustworthy data that guides their maintenance practices and operational decisions.

Moreover, the process of calibration involves comparing the readings of AC gauges against known standards, allowing technicians to identify any inaccuracies. This can effectively prevent costly mistakes, such as overcharging refrigerants or failing to detect leaks. By establishing a regular calibration schedule, HVAC companies not only improve the reliability of their tools but also enhance the overall health of their systems. Ultimately, investing time and resources into calibrating AC gauges translates into better service quality, prolongs equipment lifespan, and enhances customer satisfaction, showcasing the seamless interplay between precision and efficiency in the HVAC industry.

Related Posts

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

5 Essential Tips for Choosing the Right Liquid Filled Gauges

-

The Ultimate Guide to Choosing the Perfect Digital Manometer for Your Needs

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments