Top 10 Essential Instruments and Gauges Every Engineer Should Know

In the ever-evolving landscape of engineering, mastery over fundamental instruments and gauges is crucial for professionals striving to ensure precision, efficiency, and safety in their projects. A recent report by Engineering New Record highlights that nearly 70% of engineering failures can be traced back to improper measurements and instrumentation usage. Consequently, it becomes imperative for engineers to familiarize themselves with essential tools that not only enhance their capabilities but also facilitate informed decision-making in design and execution.

The significance of instruments and gauges extends across various engineering disciplines, including mechanical, civil, and electrical sectors. For instance, according to the American Society of Mechanical Engineers, proper utilization of measuring instruments can improve productivity by approximately 30%. This underscores the vital role these tools play in streamlining processes and minimizing errors. As we delve into the top 10 essential instruments and gauges every engineer should know, we will explore their applications, benefits, and the critical knowledge they provide in fostering a robust engineering practice.

Essential Measuring Tools for Engineers: Overview

Engineers rely heavily on precise measurements to ensure their designs and constructions meet stringent standards and specifications. Among the essential measuring tools, calipers and micrometers are foundational instruments that facilitate accurate measurements of lengths, diameters, and depth. According to the National Institute of Standards and Technology, the use of precise measuring tools can reduce manufacturing errors by up to 30%, underscoring their importance in the engineering field.

Another vital category includes electronic measuring devices such as multimeters and oscilloscopes. Multimeters provide engineers with the ability to measure voltage, current, and resistance, which are critical in electrical engineering applications. The International Electrotechnical Commission reports that the proper use of multimeters can significantly enhance diagnostic capabilities, leading to improved safety and efficiency in both design and maintenance. Similarly, oscilloscopes are indispensable for visualizing electrical signals, enabling engineers to analyze circuit behavior effectively, thereby ensuring optimal functionality in complex electronic systems.

Overall, mastering the use of these essential measuring tools not only enhances productivity but also elevates the quality of engineering output, reinforcing the adage that accurate measurements are the cornerstone of successful engineering projects.

Fundamental Gauges for Accurate Engineering Measurements

Accurate measurements are at the heart of engineering, where precision dictates the success of any project. Among the essential gauges that every engineer should be familiar with, the caliper stands out as a versatile instrument that measures dimensions with great accuracy, whether in millimeters or inches.

Calipers come in various forms, such as digital, dial, and vernier, each providing unique advantages in specific applications. Engineers frequently rely on calipers to ensure that components fit correctly, which is crucial in fields like manufacturing and construction.

Another fundamental tool is the micrometer, which offers even finer precision for gauging small distances or thicknesses. With its capability to measure within microns, the micrometer is indispensable in tasks that require exact tolerances, such as machining and material testing.

Similarly, the use of measuring tapes, although simpler, remains vital in field applications where quick and reliable distance measurements are necessary. Each of these instruments plays a significant role in the engineering process, emphasizing the importance of accurate engineering measurements to enhance design, quality control, and overall efficiency in projects.

Common Engineering Instruments and Their Applications

In the field of engineering, mastering a variety of instruments and gauges is crucial for ensuring precision and accuracy in various applications. One of the most common instruments is the caliper, which is essential for measuring dimensions of objects, whether in mechanical design or manufacturing processes. It provides both external and internal measurements, allowing engineers to check tolerances and ensure parts fit correctly. Another fundamental instrument is the micrometer, which allows for highly accurate measurements of small distances. This precision is particularly important in fields like aerospace and automotive engineering, where even the slightest variation can lead to significant discrepancies.

Pressure gauges are also vital in engineering applications, particularly in mechanical and fluid systems. These gauges measure the pressure of gases and liquids, helping engineers ensure that systems operate within safe limits. Additionally, tools like multimeters are indispensable for electrical engineering, as they can measure voltage, current, and resistance, thus allowing engineers to troubleshoot circuits effectively. Together, these instruments form the backbone of engineering practices, enabling professionals to design, test, and analyze components with confidence and accuracy. Understanding how and when to use each of these tools is key to successful engineering outcomes.

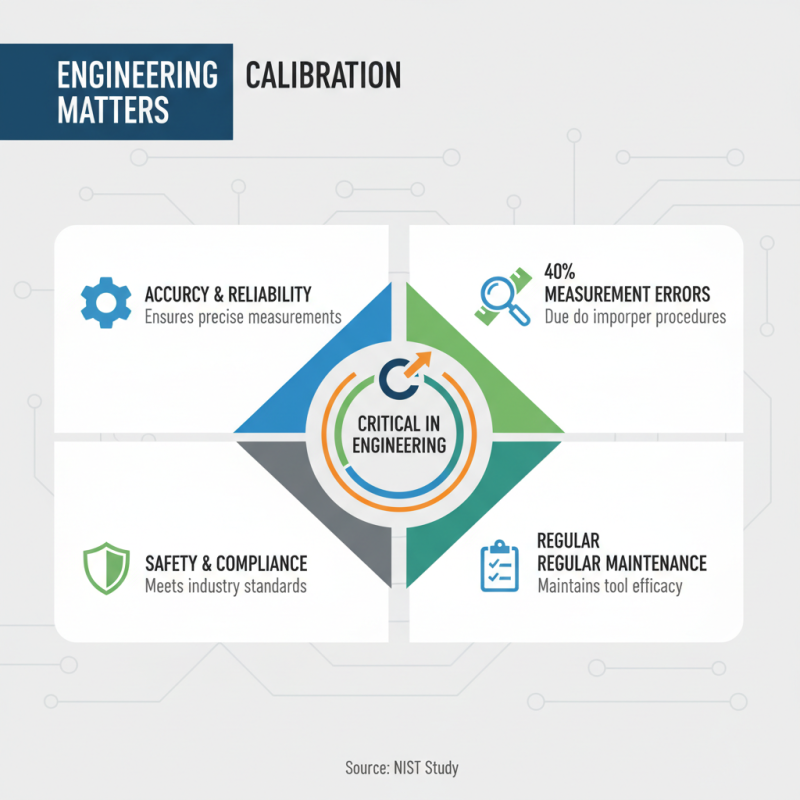

Understanding Calibration: Importance and Techniques

Calibration is a critical aspect of engineering that ensures the accuracy and reliability of measurements taken by various instruments and gauges. According to a study by the National Institute of Standards and Technology, approximately 40% of measuring errors can be attributed to improper calibration procedures. This statistic highlights the importance of understanding calibration techniques within various engineering disciplines. Engineers must regularly calibrate tools to maintain their efficacy and adhere to industry standards, which not only affects project quality but also impacts safety and compliance with regulatory requirements.

Effective calibration techniques vary depending on the instruments used. For instance, in fields like mechanical and electrical engineering, traceable calibration against standard references can significantly reduce measurement uncertainty. A report from the International Organization for Standardization indicates that companies implementing systematic calibration protocols are able to enhance their product quality by up to 25%. This improvement not only reduces the risk of costly errors but also builds client trust through consistent reliability. Educating engineers about these vital calibration practices thus ensures they can uphold the highest standards in their work, ultimately benefiting the entire industry.

Safety Instruments Every Engineer Should Be Familiar With

Safety instruments are critical tools that every engineer should be well-versed in to ensure not only their safety but also the safety of their colleagues and the integrity of their projects. Among the essential safety instruments, personal protective equipment (PPE) such as helmets, gloves, and safety goggles play a vital role in preventing injuries in hazardous environments. Furthermore, the use of gas detectors is crucial in identifying harmful gases that can pose serious health risks, allowing for timely interventions to safeguard workers.

In addition to personal protection, engineers should be knowledgeable about various measurement gauges that monitor environmental conditions and operational safety. For instance, pressure gauges are indispensable in many engineering fields, helping to prevent over-pressurization in systems that can lead to explosions or system failures. Similarly, temperature sensors can indicate unsafe conditions in processes where overheating could result in catastrophic outcomes. Familiarity with these instruments not only enhances individual safety but also promotes a culture of safety within engineering teams, contributing to the overall success of projects.

Related Posts

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

What are Marsh Pressure Gauges and Their Critical Role in Industrial Applications?

-

How to Choose Differential Pressure Gauges for Optimal Performance in Industrial Applications

-

2025 Top 10 Innovations in Pulp and Paper Industry: Transforming Sustainability with 80% Recycled Fiber Usage

-

Top 10 Tips for Choosing the Best Test Gauges for Accurate Measurements

-

Choosing the Right Liquid Filled Gauges for Optimal Performance and Accuracy in Industrial Applications

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments