7 Essential Low Pressure Gauges You Need for Accurate Measurements

In the world of industrial applications, the precision of measurements plays a crucial role in ensuring operational efficiency and safety. Among various measurement tools, low pressure gauges are essential for monitoring and controlling processes that require accuracy in low pressure settings, such as HVAC systems and chemical processing. According to a report by the International Society of Automation, approximately 40% of process-related failures can be traced back to inaccurate pressure measurements. This highlights the need for reliable and precise low pressure gauges that can provide accurate readings, thus preventing costly downtimes and hazardous situations.

In this blog, we will explore seven essential low pressure gauges that are fundamental for achieving accurate measurements, delving into their features, applications, and the critical role they play in various industries.

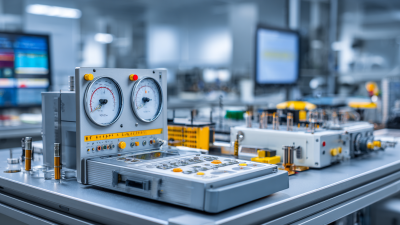

The Importance of Low Pressure Gauges in Industrial Applications

In industrial applications, the importance of low pressure gauges cannot be overstated. These specialized instruments are crucial for monitoring and regulating pressure in various systems, ensuring optimal performance and safety. Whether in chemical processing, HVAC systems, or food and beverage production, accurate pressure readings can prevent system failures and enhance operational efficiency. By providing real-time feedback, low pressure gauges enable engineers and technicians to make informed decisions that can avert potential hazards and downtime.

In industrial applications, the importance of low pressure gauges cannot be overstated. These specialized instruments are crucial for monitoring and regulating pressure in various systems, ensuring optimal performance and safety. Whether in chemical processing, HVAC systems, or food and beverage production, accurate pressure readings can prevent system failures and enhance operational efficiency. By providing real-time feedback, low pressure gauges enable engineers and technicians to make informed decisions that can avert potential hazards and downtime.

Moreover, the reliability of low pressure gauges directly affects the quality of the products being manufactured. In processes where precision is essential, such as pharmaceuticals and semiconductor manufacturing, even minor pressure fluctuations can lead to significant variations in the final output. Utilizing high-quality low pressure gauges ensures that any deviations are promptly detected and corrected. As a result, industries can maintain stringent quality control while minimizing waste and maximizing productivity, making these gauges an indispensable tool in any industrial setting.

Key Features to Look for in a Quality Low Pressure Gauge

When selecting a low pressure gauge, the first key feature to consider is accuracy. Accurate measurements are vital for ensuring operational efficiency and safety in various applications. Look for gauges that offer a high degree of precision, typically indicated by their calibration standards. This ensures that your readings are not only reliable but also repeatable over time, providing peace of mind in critical settings.

Another important aspect is the construction material of the gauge. High-quality materials not only enhance durability but also affect the gauge’s resistance to environmental factors like humidity and temperature fluctuations. Stainless steel or brass bodies are commonly recommended for their resilience and ability to withstand harsh conditions. Additionally, consider gauges with clear and easy-to-read dials or digital displays, as readability can significantly impact the usability of the instrument in fast-paced environments.

Investing in features like shock resistance and vibration damping can also prolong the lifespan of your gauge and maintain measurement integrity.

Top 3 Types of Low Pressure Gauges and Their Applications

When it comes to measuring low pressure, selecting the right gauge is crucial for accurate readings.

The three most common types of low pressure gauges are Bourdon tube gauges, diaphragm gauges, and digital gauges, each with unique applications.

Bourdon tube gauges are ideal for general purpose pressure measurement, especially in HVAC systems and water systems, due to their mechanical simplicity and reliability.

Diaphragm gauges, on the other hand, excel in low-pressure applications that require higher sensitivity. They are often used in laboratories and process industries where precise measurements are critical.

For instances where digital accuracy is a must, digital gauges provide real-time readings and easy-to-read displays, making them perfect for use in environments where pressure fluctuates frequently.

Tips for selecting the right low pressure gauge include ensuring that the gauge's pressure range is suitable for your application and considering the operating environment.

Additionally, maintaining regular calibration will help preserve the accuracy of your readings, ultimately enhancing the reliability of your systems.

Always consult manufacturer specifications to choose the right material and design for your specific needs.

Understanding Measurement Range and Accuracy in Low Pressure Gauges

When selecting low pressure gauges, understanding measurement range and accuracy is crucial for achieving reliable results. The measurement range indicates the span of pressures that a gauge can accurately record, which is particularly important in applications that involve delicate systems or substances. Choosing a gauge with an appropriate measurement range ensures that it can handle the expected variations without risk of damage or inaccurate readings. For example, a gauge designed to measure pressures in the range of 0-30 psi may not perform well in a system where pressures can occasionally spike beyond this limit.

Accuracy, on the other hand, refers to how close the measurements are to the actual pressure values. Low pressure gauges often come with specified accuracy levels, which can affect decision-making processes in specific applications. Factors such as temperature, vibrations, and the presence of corrosive materials can impact a gauge's accuracy. Therefore, selecting gauges with the right calibration and materials is essential for maintaining accurate readings over time. By prioritizing both measurement range and accuracy, users can ensure that they have the right tools for precise monitoring in all their low-pressure applications.

7 Essential Low Pressure Gauges You Need for Accurate Measurements

| Gauge Type | Measurement Range | Accuracy | Connection Type | Features |

|---|---|---|---|---|

| Digital Low Pressure Gauge | 0 to 15 psi | ±0.5% Full Scale | ¼" NPT | Backlight, Data Hold |

| Analog Bourdon Tube Gauge | 0 to 30 psi | ±1.0% Full Scale | ½" NPT | All Weather, Rust Proof |

| Digital Manometer | -5 to 5 psi | ±0.3% Full Scale | USB, Bluetooth | Data Logging, USB Charging |

| Membrane Pressure Gauge | 0 to 1 bar | ±1.0% Full Scale | ¼" NPT | Corrosion Resistant |

| Low Pressure Differential Gauge | 0 to 10 in. H2O | ±0.25% Full Scale | ¼" NPT | High Sensitivity |

| Water Pressure Gauge | 0 to 10 psi | ±2.0% Full Scale | ½" NPT | Plastic Housing |

| Calibration Test Gauge | 0 to 5 psi | ±0.5% Full Scale | ¼" NPT | Portable, Battery Operation |

Maintenance Tips for Extending the Life of Your Low Pressure Gauges

Low pressure gauges are critical tools in various industrial applications, ensuring accurate pressure readings that can affect operational efficiency. To extend the lifespan of these instruments, regular maintenance is essential. According to a recent report by the Pressure Instrumentation Association, improper care can lead to a 30% decrease in gauge accuracy over time.

One key tip for maintaining your low pressure gauges is to ensure that they are calibrated regularly. Calibration should be performed at least once a year, or more frequently if the gauges are subjected to harsh conditions. Additionally, keeping gauges free from contaminants and using protective covers can help prevent damage from environmental factors, thereby enhancing their durability.

Another important maintenance aspect is to regularly check for leaks and connections. Even minor leaks can compromise the accuracy of measurements. A study published in the Journal of Industrial Instrumentation suggests that nearly 20% of pressure measurement inaccuracies stem from poor connections. By ensuring tight seals and promptly addressing potential leaks, users can significantly enhance the reliability and lifespan of their low pressure gauges.

7 Essential Low Pressure Gauges You Need for Accurate Measurements

This bar chart displays the accuracy levels of seven essential low pressure gauges used in various applications. The measurements illustrate the percentage of accuracy achieved in real-world scenarios.

Related Posts

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

The Future of Test Instruments in Industry Innovation

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

The Ultimate Guide to Choosing the Perfect Digital Manometer for Your Needs

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments