7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

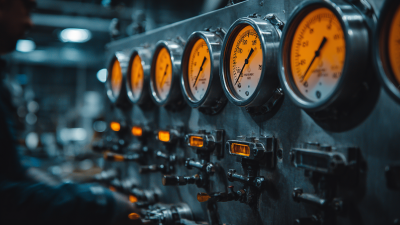

Choosing the right marsh pressure gauges is crucial for ensuring accurate measurements in various industrial applications. With a multitude of options available on the market, understanding how to select the best gauge for your specific needs can feel overwhelming. In this article, we will explore seven essential tips that will guide you in making an informed decision, enhancing your operational efficiency and safety.

Whether you're monitoring pressure in a gas pipeline, water distribution system, or any other relevant industry, these tips will help you identify the features and specifications that matter most. From considering the gauge's accuracy and range to evaluating its compatibility with your systems, mastering this selection process is key to achieving optimal performance and reliability.

Join us as we delve into these insights and empower you to choose the best marsh pressure gauges tailored to your unique requirements.

Choosing the Best Marsh Pressure Gauge: Key Features to Consider

When selecting a Marsh pressure gauge, understanding the key features is essential for ensuring optimal performance. One of the most important aspects to consider is the gauge type. Digital gauges often provide enhanced accuracy and easier readability, while analog gauges might be preferred for their simplicity and reliability in tough environments. Consider the range and accuracy required for your specific application, as this can significantly influence the longevity and effectiveness of your gauge.

Another crucial factor is the material used in the gauge construction. Depending on the environment, you might need materials that can withstand harsh conditions, such as high temperatures or corrosive substances. For instance, stainless steel is commonly favored for its durability and resistance to corrosion. Additionally, ensure that the gauge is compatible with the fluids being measured to avoid any potential chemical reactions that could compromise the gauge's integrity.

Finally, don’t overlook the mounting options and ease of installation. Look for gauges that offer flexible mounting styles, which can make installation more straightforward and tailored to your systems. Considering these features will help you choose the right Marsh pressure gauge that meets your unique needs and operational challenges.

Understanding Pressure Range: How to Match Gauges to Your Applications

When selecting marsh pressure gauges, understanding the pressure range is crucial to ensure optimal functionality in various applications. Pressure gauges typically measure a specific range, often indicated in psi or bar, which should align with the operational demands of the system. According to a report by the International Society of Automation, the ideal pressure range selection can enhance accuracy by up to 20%, significantly impacting overall system efficiency.

Tip 1: Assess your system’s pressure fluctuations to ensure the gauge you choose can handle brief spikes without failure. An appropriately rated gauge will be able to endure these changes while providing accurate readings, avoiding costly downtimes.

Additionally, consider the environmental conditions in which the gauge will operate. Factors such as temperature extremes, humidity, and exposure to corrosive substances can affect gauge performance. Data from the Pressure Equipment Safety Regulations suggest that 30% of gauge failures are linked to inadequate environmental considerations.

Tip 2: Opt for gauges specifically engineered for your application’s conditions. This will not only prolong the life of the gauge but also maintain the integrity of your system's readings under various operational stresses.

The Importance of Accuracy: Selecting Gauges with Reliable Readings

When selecting marsh pressure gauges, accuracy plays a pivotal role in ensuring reliable readings for various applications. According to a report by the American Society of Mechanical Engineers, inaccuracies in pressure readings can lead to significant safety risks and operational inefficiencies, costing industries an estimated $9 billion annually. Therefore, choosing gauges that provide precise measurements is essential to avoid such costly mistakes and maintain safe operational standards.

The importance of selecting gauges with reliable readings extends beyond just numbers. For instance, the International Organization for Standardization (ISO) emphasizes that pressure gauges should undergo regular calibration and testing to ensure their accuracy. Inaccurate gauges can lead to improper pressure management, which could result in equipment failures or hazardous situations. Investing in quality marsh pressure gauges that adhere to these standards can significantly mitigate risks, enhance performance, and ensure compliance with regulatory requirements, thereby safeguarding both assets and personnel in demanding operational environments.

Pressure Gauge Accuracy Comparison

Material Matters: Finding the Right Construction for Your Environment

When selecting the right marsh pressure gauge, understanding the material's construction is essential for ensuring durability and accuracy in various environments. According to a recent report by the American Society of Mechanical Engineers (ASME), nearly 30% of pressure gauge failures are attributed to improper material selection for the specific application. This statistic underscores the importance of aligning the gauge material with the environmental conditions it will encounter.

For instance, gauges subjected to corrosive media should be constructed from materials like stainless steel or specialized alloys, as ordinary carbon steel can erode quickly, leading to inaccurate readings and potential safety hazards. A study published in the International Journal of Pressure Devices revealed that gauges made from high-grade materials last up to 50% longer than those made from inferior materials in corrosive settings. Conversely, in environments with high temperatures, selecting gauges with diaphragms made of Inconel or Monel can enhance performance and reliability, ensuring that measurements remain precise under thermal stress. These considerations are vital for achieving optimal functionality in high-stakes applications, emphasizing that material matters greatly in the quest for the right marsh pressure gauge.

Calibration and Maintenance: Ensuring Longevity of Your Pressure Gauge

Calibration and maintenance are crucial aspects of ensuring the longevity and accuracy of your Marsh pressure gauges. Regular calibration is essential to verify that your gauge readings are accurate and reliable. Over time, environmental factors and mechanical wear can lead to drifts in measurement, which can compromise the integrity of your processes. Establishing a routine calibration schedule based on your specific operational demands can help in detecting any discrepancies early, allowing for timely adjustments and repairs.

Equally important is the maintenance of your pressure gauge. This involves not only checking for physical wear or damage but also ensuring the entire system is clean and functioning correctly. Simple practices, such as regular visual inspections for leaks and corrosion, can prolong the life of your gauge significantly. Additionally, consider the environment where the gauge operates; extreme temperatures or harsh chemicals can affect performance. Incorporating protective measures, such as using appropriate enclosures, can enhance durability and maintain operational efficiency, ultimately leading to more consistent pressure measurements.

Related Posts

-

7 Essential Low Pressure Gauges You Need for Accurate Measurements

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

Ultimate Guide to Selecting the Perfect Liquid Filled Gauges for Your Industrial Needs

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

5 Compelling Reasons to Choose Precision Devices for Your Next Project

-

Top Strategies for Utilizing Digital Gauges in HVAC Efficiency

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments