7 Essential Tips for Choosing Precision Instruments for Your Business Needs

In today’s competitive landscape, selecting the right precision instruments is critical for businesses aiming to enhance operational efficiency and maintain high-quality standards. According to a recent report by MarketsandMarkets, the global precision instruments market is projected to reach $20 billion by 2025, driven by increasing demand across various industries such as manufacturing, healthcare, and aerospace. The accurate measurement and analysis capabilities provided by these instruments are essential for optimizing production processes and ensuring product reliability. Choosing the right tools not only ensures compliance with industry standards but also significantly reduces error margins, leading to improved customer satisfaction and reduced operational costs. In this blog, we will explore seven essential tips to guide you in selecting precision instruments that best meet your business needs.

Understanding Your Business Requirements for Precision Instruments

When it comes to selecting precision instruments for your business, understanding your specific requirements is paramount. According to a report by the Precision Measurement Association, 70% of businesses face significant operational inefficiencies due to mismatched instrumentation. This highlights the need for a detailed assessment of your existing workflows, environmental conditions, and the precision levels your industry demands. For example, industries such as aerospace and pharmaceuticals require instruments with tolerances as tight as ±0.001 mm, while manufacturing processes may accommodate wider margins.

Moreover, market research shows that businesses that invest time in defining their precision needs typically see a 40% reduction in rework and waste. This not only enhances productivity but can lead to significant cost savings. Taking the time to analyze factors such as measurement range, accuracy, and even the potential for future scalability can make all the difference. Brands that prioritize understanding their requirements can streamline their operations and maintain competitive advantages in an ever-evolving market.

7 Essential Tips for Choosing Precision Instruments for Your Business Needs

| Tip Number | Essential Tip | Description | Consideration Level |

|---|---|---|---|

| 1 | Assess Your Requirements | Understand the specific measurements needed for your processes. | High |

| 2 | Evaluate Accuracy Levels | Choose instruments that meet or exceed your accuracy requirements. | High |

| 3 | Check Calibration Options | Ensure the instruments can be easily calibrated to maintain accuracy. | Medium |

| 4 | Consider Environmental Conditions | Choose instruments suitable for the specific environment they will be used in. | High |

| 5 | Review User-Friendliness | Select instruments that are easy to use and require minimal training. | Medium |

| 6 | Assess Maintenance Needs | Consider how often the instruments will need maintenance and service. | Medium |

| 7 | Factor in Budget Constraints | Ensure that the chosen instruments fit within your budget while meeting needs. | High |

Evaluating the Accuracy and Reliability of Measurement Tools

When selecting precision instruments for your business needs, evaluating the accuracy and reliability of measurement tools is paramount. According to a report by the National Institute of Standards and Technology (NIST), measurement inaccuracies can lead to significant financial losses, potentially up to 25% of revenue in manufacturing settings. This highlights the critical importance of investing in high-quality instruments that deliver precise data.

Moreover, different industries have varying standards for accuracy. For instance, medical devices must adhere to strict regulations, as per the FDA guidelines, which require measurements to have an accuracy rate of at least 95% in clinical settings. This level of precision is essential not only for compliance but also for ensuring patient safety. Businesses should consider regular calibration and maintenance of precision tools, as studies indicate that improperly calibrated instruments can yield results that deviate by as much as 30%.

Hence, comprehensive evaluation of measurement tools—by considering their specifications, calibration history, and reliability ratings—can significantly enhance operational efficiency and accuracy in any sector.

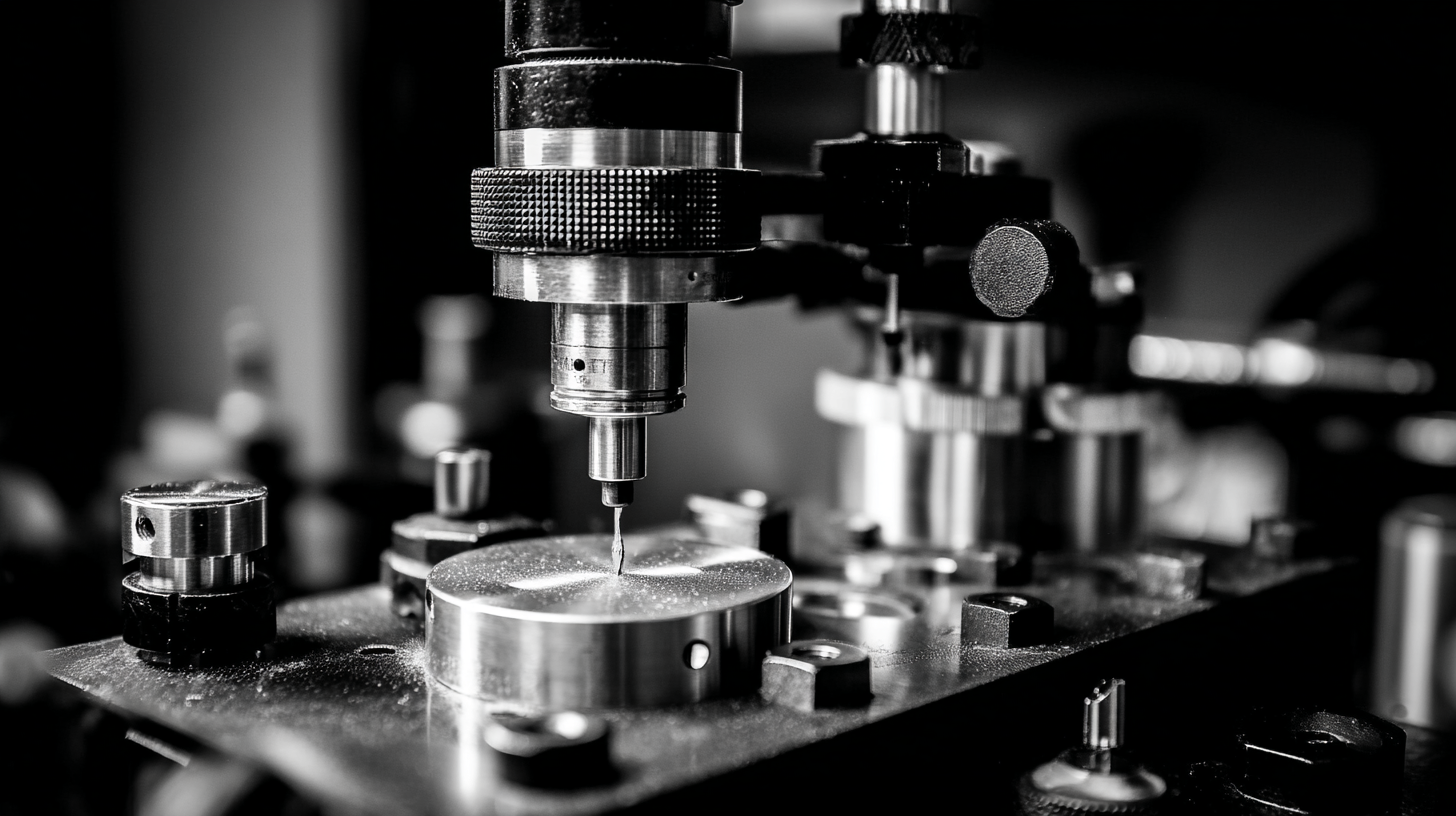

Exploring Different Types of Precision Instruments Available

When it comes to selecting precision instruments for your business, understanding the various types available is crucial. Precision instruments are designed to provide high accuracy and reliability, which is essential for industries such as manufacturing, research, and quality control. Common types include calipers, micrometers, and digital gauges, each serving specific purposes.

Calipers are versatile tools for measuring dimensions accurately, while micrometers offer precision measurements for smaller sizes. Digital gauges, on the other hand, provide quick and easy readings, making them an excellent choice for those who prioritize speed alongside accuracy.

Beyond these basics, businesses may also consider specialized instruments like coordinate measuring machines (CMM) and optical comparators. CMMs are essential for three-dimensional measurements and are widely used in quality assurance processes. Optical comparators allow for the examination of part dimensions by projecting their silhouettes onto a screen, making it easier to identify deviations from specifications.

Understanding these variations helps businesses select the right tools to meet their unique operational needs, ensuring enhanced performance and efficiency in measurement tasks.

Assessing Vendor Reputation and Customer Support Services

When selecting precision instruments for your business, assessing vendor reputation is crucial. A reputable vendor not only provides high-quality products but also instills confidence in their ability to support your business needs. Researching online reviews, testimonials, and case studies can provide insight into the vendor’s reliability. Look for vendors that have a strong industry presence and are recommended by peers. Engaging in forums and professional associations can also help you gather firsthand accounts of their service quality and credibility.

Customer support services should be a top consideration as well. The best precision instruments are often accompanied by comprehensive support, including installation guidance, troubleshooting, and ongoing maintenance. Ensure the vendor offers prompt and accessible customer support, with multiple communication channels such as phone, email, or live chat. Additionally, verify their scalability—can they support your business as it grows? A vendor committed to excellent customer service can significantly enhance your experience and help maximize the value of your investment in precision instruments.

Assessing Vendor Reputation and Customer Support Services

This chart displays the evaluation of various aspects of vendor reputation and customer support services based on a survey of business users. Each category reflects the percentage of users who rated their experience positively.

Budgeting for Precision Instruments: Cost vs. Quality Considerations

When it comes to budgeting for precision instruments, businesses often grapple with the dilemma of cost versus quality. While it may be tempting to opt for the most economical options available, a thorough understanding of the long-term implications of such choices is crucial. Inferior instruments can lead to inaccurate measurements, increased maintenance costs, and ultimately, a negative impact on product quality. Therefore, investing in high-quality precision instruments at a higher upfront cost may yield significant savings in the long run through enhanced reliability and performance.

Another critical aspect is the alignment of precision instruments with the specific needs of your business. This involves not only assessing the initial financial outlay but also considering factors such as durability, the frequency of use, and the potential for future scalability. Higher-quality instruments often come with better technical support, warranties, and upgrades, which are vital for ongoing operations. By carefully balancing cost with quality, businesses can ensure that their precision tools not only meet current requirements but also adapt to future challenges, ultimately supporting growth and efficiency in their operations.

Related Posts

-

Ultimate Guide to Choosing the Right Precision Instruments for Your Needs

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

Understanding the Benefits of Liquid Filled Pressure Gauges for Optimal Industrial Performance

-

Challenges Encountered in Pulp and Paper Industry Operations

-

Navigating the Challenges of Precision Devices in Today's High Demand Markets

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments