2025 How to Choose the Best Refrigeration Gauges for Your Needs

Choosing the right refrigeration gauges is crucial for anyone involved in the refrigeration and HVAC industry. As technology continues to advance, so too does the need for reliable and accurate tools that can enhance efficiency and ensure proper maintenance. According to John Smith, a renowned expert in the refrigeration sector, "The right refrigeration gauges not only streamline the diagnostic process but also save time and money in the long run."

In 2025, understanding how to select the best refrigeration gauges for your specific needs is more important than ever. With an abundance of options available in the market, it is essential to consider factors such as accuracy, ease of use, and the types of refrigerants being measured. Refrigeration gauges are pivotal in diagnosing system performance, and an improper selection can lead to inefficiencies and costly repairs.

As we navigate through the complexities of modern refrigeration systems, equipping ourselves with the right tools is an investment in both safety and performance. By paying attention to the critical features and functionality of refrigeration gauges, technicians can optimize their work processes and ensure the longevity of the systems they service.

Understanding Refrigeration Gauges: Types and Functions

Understanding refrigeration gauges is essential for anyone working in the HVAC field or dealing with refrigeration systems. These tools are vital for monitoring the pressure and temperature within a system, which allows technicians to diagnose issues, ensure efficient operation, and maintain optimal performance. There are primarily two types of refrigeration gauges: manifold gauges and vacuum gauges.

Manifold gauges typically feature one gauge for high pressure, one for low pressure, and two service hoses. They are used to measure the pressure readings of refrigerants and to facilitate the charging, recovery, and evacuation processes.

Vacuum gauges, on the other hand, measure the vacuum level in a system, which is crucial when checking for leaks or assessing the state of a refrigeration system before charging it with refrigerant. Some advanced vacuum gauges are digital and provide more precise readings, essential for ensuring that the system is adequately evacuated of moisture and air.

Understanding the specific functions and applications of each type of gauge will help technicians choose the best tools for their needs, ultimately leading to improved efficiency and reliability in refrigeration systems. Furthermore, the choice of gauge can affect how effectively a technician can respond to issues that arise, reinforcing the importance of selecting the right type for specific tasks.

Key Features to Consider When Selecting Refrigeration Gauges

When selecting refrigeration gauges, it's essential to focus on key features that will meet your specific needs. Firstly, consider the gauge type—analog or digital. Analog gauges are traditional and provide a straightforward readout, while digital gauges often offer more precision and additional functionalities, such as data logging and advanced diagnostics. The choice between these depends on the user's preference for ease of use and the technical demands of their refrigeration applications.

Another vital aspect to take into account is the pressure range and accuracy of the gauge. Ensure that the gauge can accurately measure the pressures typical for the systems you work with, as incorrect readings can lead to improper maintenance and potential system failures. Look for gauges with a higher accuracy rating to reduce errors in your measurements, enhancing both efficiency and safety.

**Tips:** If you anticipate working with various refrigerants, opt for gauges that are compatible with a wide range of substances. Also, prioritize durability; a robust gauge can withstand rough handling in the field and deliver reliable readings over time. Finally, ease of readability should not be overlooked—choose gauges with clear markings or a large display for quick, at-a-glance information.

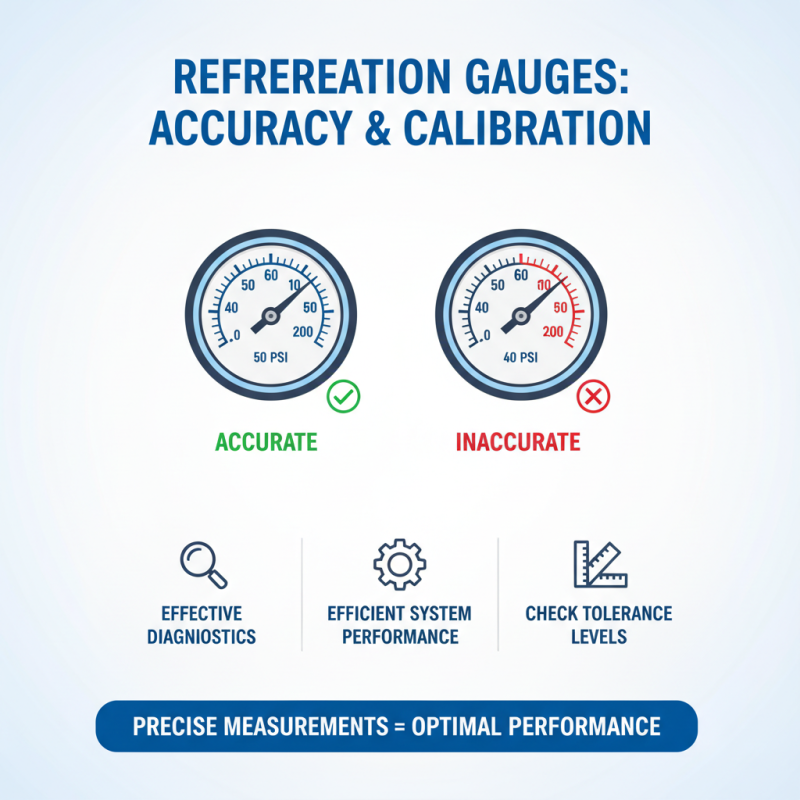

How to Evaluate Accuracy and Calibration in Refrigeration Gauges

When selecting refrigeration gauges, one of the most critical considerations is their accuracy and calibration. Accurate gauges are essential for effective diagnostics and efficient system performance. To assess accuracy, it's important to check if the gauge displays precise measurements under different pressure conditions. Users should look for specifications that detail the gauge's tolerance levels, as this can indicate potential discrepancies in readings during operation.

Calibration is another pivotal factor in maintaining the reliability of refrigeration gauges. Over time, gauges can drift from their original calibration due to wear and environmental factors. It is advisable to choose gauges that can be easily calibrated or have a recalibration service available. Regularly scheduled calibration checks not only ensure consistent performance but also prevent costly mistakes that may arise from inaccurate readings. By understanding these aspects of accuracy and calibration, users can make informed choices that enhance their refrigerant management practices.

Comparing Digital and Analog Refrigeration Gauges: Pros and Cons

When choosing refrigeration gauges, HVAC professionals often find themselves weighing the benefits of digital versus analog options. According to a report by the Air Conditioning Contractors of America (ACCA), the increasing accuracy and ease of use associated with digital gauges have led to a 25% rise in adoption rates among technicians in recent years. Digital gauges typically offer precise readings with less susceptibility to human error, making them ideal for intricate systems where exact measurements are crucial. Additionally, features like Bluetooth connectivity for real-time data transfer to mobile devices enhance operational efficiency, allowing technicians to monitor performance remotely.

On the other hand, analog gauges still hold their ground in specific scenarios. With a simpler design and no reliance on batteries or electronic components, they are often considered more durable, especially in harsh working environments. Research from the Environmental Protection Agency (EPA) indicates that about 30% of field technicians prefer analog gauges for their reliability and ease of maintenance, particularly in settings where power sources are limited. Moreover, the immediate visual feedback provided by the analog dial can be beneficial during high-pressure situations, where quick assessments are essential. Therefore, understanding the pros and cons of both types can significantly influence the decision-making process for professionals seeking efficient and reliable refrigeration solutions.

2025 How to Choose the Best Refrigeration Gauges for Your Needs - Comparing Digital and Analog Refrigeration Gauges: Pros and Cons

| Feature | Digital Gauges | Analog Gauges |

|---|---|---|

| Accuracy | High precision | Moderate accuracy |

| Readability | Easy to read, often with digital display | Can be difficult to read in low light |

| Battery Requirement | Requires batteries | No batteries needed |

| Durability | More sensitive electronic components | Generally more rugged |

| Cost | Usually more expensive | Typically more affordable |

| Data Logging | Often includes data logging features | No data logging capabilities |

| Calibration | Often requires periodic recalibration | Generally stable over time without frequent calibration |

Budgeting for Quality: Cost Considerations for Refrigeration Gauges

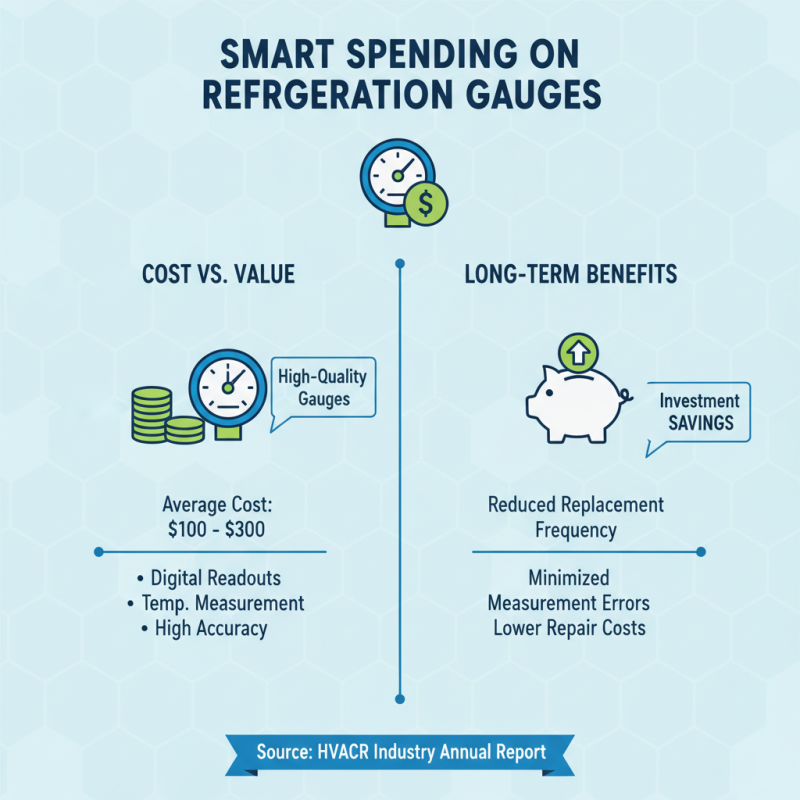

When selecting refrigeration gauges, budgeting becomes a critical factor in ensuring you get the most value without compromising quality. According to the HVACR Industry's annual report, the average cost of high-quality refrigeration gauges ranges from $100 to $300, depending on features such as digital readouts, temperature measurement capabilities, and accuracy levels. While it might be tempting to opt for cheaper options, investing in reliable gauges can lead to long-term savings by reducing the frequency of tool replacement and minimizing potential measurement errors that can escalate repair costs.

Furthermore, industry insights reveal that professionals who invest in higher-end gauges report a significant increase in measurement reliability—up to 25% more accurate in some cases. This increased accuracy not only boosts efficiency during maintenance tasks but also ensures compliance with safety standards, which can prevent costly fines or accidents. Therefore, while budgeting for refrigeration gauges, it is crucial to assess both the initial costs and the potential long-term benefits that quality equipment can bring, reinforcing the age-old adage that investing wisely today often pays dividends tomorrow.

Related Posts

-

7 Essential Tips for Choosing the Right Refrigeration Gauges to Boost Efficiency by 30%

-

7 Essential Tips for Choosing the Best Refrigeration Gauges for Your Needs

-

Why Measuring Tools Are Essential for Accurate Data Analysis and Decision Making

-

How to Effectively Use Measuring Instruments: A Comprehensive Tutorial for Beginners

-

Ultimate Guide to Understanding Measuring Instruments for Your Business Success

-

How to Choose the Right Measuring Tool for Your DIY Projects at Home

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments