What are Marsh Pressure Gauges and Their Critical Role in Industrial Applications?

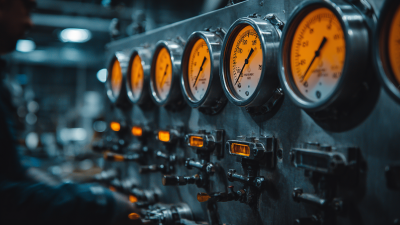

Marsh pressure gauges are indispensable instruments in various industrial applications, providing critical measurements essential for safety and efficiency. As industries increasingly prioritize precision and reliability, understanding the functionality and significance of marsh pressure gauges becomes paramount. These gauges are specifically designed to monitor pressure levels in different mediums, ensuring that systems operate within safe parameters. Their unique design and construction not only enhance durability but also increase accuracy, making them vital for processes ranging from oil and gas extraction to chemical manufacturing. In this blog, we will explore what marsh pressure gauges are, how they work, and their crucial role in maintaining operational integrity across diverse industrial settings. Whether you are an industry professional or simply curious about industrial instrumentation, this exploration will highlight the importance of marsh pressure gauges in modern applications.

Understanding Marsh Pressure Gauges: A Comprehensive Overview

Marsh pressure gauges play a vital role in various industrial applications, providing accurate pressure readings that are crucial for operational safety and efficiency. Understanding the mechanism behind these gauges is essential for industries reliant on precise pressure measurements. Unlike traditional gauges, Marsh pressure gauges utilize a unique design featuring a diaphragm that reacts to changes in pressure, ensuring a quick and accurate response. This design not only enhances reliability but also makes it suitable for harsh environments, further emphasizing its importance in sectors such as oil and gas, chemicals, and water treatment.

Marsh pressure gauges play a vital role in various industrial applications, providing accurate pressure readings that are crucial for operational safety and efficiency. Understanding the mechanism behind these gauges is essential for industries reliant on precise pressure measurements. Unlike traditional gauges, Marsh pressure gauges utilize a unique design featuring a diaphragm that reacts to changes in pressure, ensuring a quick and accurate response. This design not only enhances reliability but also makes it suitable for harsh environments, further emphasizing its importance in sectors such as oil and gas, chemicals, and water treatment.

The application of Marsh pressure gauges extends beyond merely measuring pressure; they also provide insights into system performance and potential hazards. In industries where maintaining specific pressure levels is critical, these gauges serve as an early warning system, preventing equipment damage and ensuring safety protocols are followed. By integrating Marsh pressure gauges into their systems, companies can enhance operational efficiency, reduce downtime, and better comply with industry regulations. This comprehensive overview underscores the necessity of employing advanced measuring solutions, ensuring that industrial processes are carried out smoothly and safely.

The Importance of Accurate Pressure Measurement in Industrial Settings

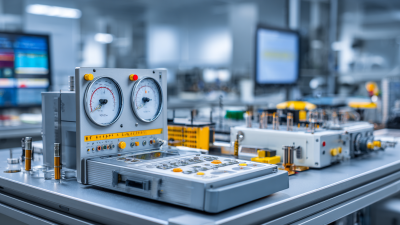

Accurate pressure measurement is paramount in industrial settings, where even minor deviations can lead to significant operational risks and inefficiencies. For instance, precision pressure sensors play a crucial role in applications such as automated drug delivery, ensuring that the correct dosage is administered without error. The ability to monitor and control pressure with high accuracy not only enhances safety protocols but also boosts productivity in various industries.

Tips for ensuring optimal pressure measurement include regularly calibrating pressure gauges to maintain their accuracy and employing advanced pressure sensor technologies that offer high dynamic range capabilities. Utilizing small-sized temperature and pressure sensors, especially in complex environments like oil and gas wells, can help maintain precise measurements in challenging conditions.

Furthermore, businesses should invest in the latest developments in pressure measurement technology. As the global pressure gauges market continues to grow, organizations that adapt to advancements will likely experience improved efficiency and productivity. By prioritizing accurate pressure measurement, industries can mitigate risks and improve their overall operational integrity.

Key Components and Functionality of Marsh Pressure Gauges

Marsh pressure gauges, renowned for their reliability and accuracy, are vital instruments in various industrial applications. At the core of these gauges are several key components, including the Bourdon tube, the movement mechanism, and the dial indicator. The Bourdon tube, typically made of brass or stainless steel, bends when pressure is applied, converting this physical change into a rotational movement that drives the needle on the dial. This mechanical process provides real-time pressure readings, which are crucial for monitoring and controlling systems in environments where safety and performance are paramount.

The functionality of Marsh pressure gauges extends beyond mere measurement. According to a market research report by Global Industry Analysts, the global pressure gauge market is projected to reach USD 5.7 billion by 2027, driven largely by the increasing demand for automation and precision in sectors like oil and gas, pharmaceuticals, and water treatment. With their ability to withstand high pressures and corrosive environments, Marsh pressure gauges are indispensable for ensuring operational efficiency and safety. As industries strive to enhance process optimization, the role of these gauges will only continue to grow, underscoring their critical importance in industrial settings.

Pressure Measurement in Industrial Applications

Marsh pressure gauges play a significant role in various industrial applications, with oil and gas sectors leading in utilization. Understanding their critical functions ensures optimal performance and safety in processes reliant on precise pressure measurements.

Applications of Marsh Pressure Gauges in Various Industries

Marsh pressure gauges are essential instruments in various industrial applications, providing accurate and reliable pressure measurements critical for safe and efficient operations. In the oil and gas industry, for instance, these gauges are used extensively in refining processes and in the monitoring of pipeline pressures. According to a report by Mordor Intelligence, the global pressure gauge market is projected to reach USD 6.6 billion by 2025, with a significant share attributed to oil and gas applications, showcasing the importance of precision measurement in this sector.

In the pharmaceutical industry, Marsh pressure gauges play a crucial role in ensuring compliance with strict regulatory standards. They are used in sterilization processes, where maintaining the correct pressure is vital for effective sterilization of equipment and materials. A study highlighted in the Journal of Pharmaceutical Sciences indicates that improper pressure readings can lead to compromised product safety, emphasizing the need for high-quality pressure measurement devices like Marsh gauges. Likewise, in the food and beverage sector, maintaining proper pressure during production processes ensures product quality and safety, reflecting the versatility and critical importance of Marsh pressure gauges across various industries.

What are Marsh Pressure Gauges and Their Critical Role in Industrial Applications?

| Industry | Application | Importance of Marsh Pressure Gauges |

|---|---|---|

| Oil & Gas | Monitoring pressure in pipelines | Ensures safe transport of materials |

| Chemical | Reactor pressure measurement | Crucial for reaction control |

| Pharmaceutical | Sterilization process monitoring | Ensures product safety and compliance |

| Food & Beverage | Pressure monitoring during bottling | Prevents product spoilage |

| Water Treatment | Pressure measurement for filtration systems | Ensures efficient operation |

Best Practices for Maintenance and Calibration of Pressure Gauges

Pressure gauges, particularly marsh pressure gauges, are vital instruments in industrial applications, ensuring the accurate monitoring of pressure levels in various systems. However, their effectiveness greatly depends on proper maintenance and calibration. Regular checks can prevent inaccuracies that may lead to system failures.

**Tip 1:** To ensure reliability, clean the gauge regularly to remove any contaminants that could affect its performance. Use a soft cloth and appropriate cleaning solutions suitable for the material of the gauge casing.

Calibration is another essential process to ensure that the gauge provides accurate readings. It should be performed at regular intervals or after significant operational changes. Keeping calibration certificates can help in tracking the calibration history of the instrument.

**Tip 2:** When calibrating, always follow the manufacturer’s guidelines for the specific model you are using. Additionally, consider using a reference gauge for comparison to verify the accuracy of your readings.

By adhering to these best practices, industries can maintain their marsh pressure gauges' reliability and performance, ultimately supporting smooth and efficient operations.

Related Posts

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

7 Surprising Benefits of Liquid Filled Pressure Gauges for Your Industry

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

Ultimate Guide to Choosing the Right Precision Instruments for Your Needs

-

7 Essential Low Pressure Gauges You Need for Accurate Measurements

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments