Top Strategies for Maximizing Efficiency with Differential Pressure Solutions

In an increasingly competitive industrial landscape, maximizing operational efficiency is paramount, and one powerful tool in achieving this is through the implementation of differential pressure solutions. According to a recent report by the International Society of Automation, optimizing differential pressure management can lead to a 20% reduction in energy consumption and a significant decrease in operational costs. These solutions not only enhance system reliability but also improve process control by providing critical insights into system performance.

As industries strive to adhere to stricter environmental regulations and sustainability goals, understanding the benefits of differential pressure becomes essential. By leveraging these advanced technologies, companies can not only ensure compliance but also boost productivity, making it a vital component in today’s efficiency strategies.

As industries strive to adhere to stricter environmental regulations and sustainability goals, understanding the benefits of differential pressure becomes essential. By leveraging these advanced technologies, companies can not only ensure compliance but also boost productivity, making it a vital component in today’s efficiency strategies.

Understanding Differential Pressure and Its Importance in Industrial Applications

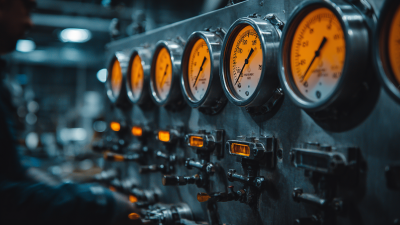

Differential pressure is a critical measurement in a variety of industrial applications, as it provides essential insights into the performance and health of equipment. It reflects the difference in pressure between two points in a system, allowing operators to monitor flow rates, detect clogs, and ensure that processes maintain optimal operating conditions. This measurement is particularly crucial in industries such as pharmaceuticals, water treatment, and HVAC, where precise control of pressure differentials can significantly impact product quality and system efficiency.

Understanding the importance of differential pressure enables industries to implement effective maintenance strategies and optimize operations. By regularly monitoring differential pressure, companies can identify potential issues before they escalate into costly problems. For example, in filtration processes, a rising differential pressure may indicate a need for filter replacement, while a sudden drop could suggest a leak or system failure. By integrating advanced differential pressure solutions, organizations can not only enhance their operational efficiency but also improve safety and reliability in their processes.

Key Metrics for Measuring Efficiency in Differential Pressure Systems

When it comes to evaluating the efficiency of differential pressure systems, certain key metrics can provide invaluable insights. One of the primary metrics is pressure drop, which measures the resistance encountered by a fluid as it flows through a system. A significant pressure drop can indicate inefficiencies, often resulting from clogged filters or poorly designed piping. By regularly monitoring this metric, operators can proactively address issues that hinder performance and optimize fluid flow within the system.

Another crucial metric is flow rate, which directly correlates with the efficiency of a differential pressure system. Understanding the flow rate allows for an assessment of how well the system is performing relative to its design specifications. Consistent monitoring can help identify fluctuations that may signal system malfunctions or the need for maintenance. Additionally, integrating real-time data analytics into the evaluation process can enhance decision-making, paving the way for timely interventions that bolster overall system efficiency. By focusing on these key metrics, businesses can maximize the effectiveness of their differential pressure solutions and ensure smoother operations.

Top Strategies for Maximizing Efficiency with Differential Pressure Solutions

This bar chart illustrates the key metrics for measuring efficiency in differential pressure systems. The data consists of various strategies and their corresponding efficiency improvements as a percentage.

Real-World Examples of Differential Pressure Solutions in Action

Differential pressure solutions are pivotal in enhancing operational efficiency across various industries. A prime example can be seen in the HVAC sector, where data from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that proper differential pressure management can lead to energy savings of 20-30%. By optimizing airflow and reducing unnecessary strain on mechanical systems, facilities can significantly lower operational costs while maintaining comfort levels.

In the pharmaceutical industry, differential pressure monitoring is essential to ensure environment integrity. According to the International Society for Pharmaceutical Engineering (ISPE), consistent differential pressure control in cleanroom environments not only ensures compliance with regulatory standards but also reduces contamination rates by up to 50%. Implementing advanced differential pressure solutions can streamline production processes, thus increasing output and bolstering overall efficiency. These real-world applications underscore the necessity of incorporating sophisticated differential pressure systems across diverse settings to maximize productivity and ensure quality.

Best Practices for Implementing Differential Pressure Strategies

Implementing differential pressure strategies effectively can significantly enhance operational efficiency across various industries. According to a report by the International Society for Measurement and Control (ISMC), optimizing differential pressure measurement can deliver a 15% increase in energy efficiency, translating to substantial cost savings. Best practices for implementing these strategies involve ensuring that the differential pressure sensors are correctly calibrated and appropriately placed to capture the most accurate data. Regular maintenance and periodic recalibration can help mitigate inaccuracies that arise due to sensor drift or clogging, thereby maintaining operational integrity.

Another crucial aspect is integrating advanced data analytics solutions with differential pressure systems. A study by the American Society of Mechanical Engineers (ASME) revealed that organizations leveraging predictive analytics can enhance their maintenance regimes, leading to a 20% reduction in unplanned downtime. By analyzing pressure data, companies can anticipate equipment failures and adjust processes proactively. Moreover, training staff on the importance of differential pressure measurements and data interpretation fosters a culture of continuous improvement, enabling teams to implement timely adjustments that maximize efficiency and productivity across their operations.

Innovations and Future Trends in Differential Pressure Technologies

The landscape of differential pressure technologies is rapidly evolving, driven by innovations that enhance measurement accuracy and operational efficiency. As industries strive for higher levels of productivity, advanced differential pressure solutions have emerged at the forefront. According to a recent market research report by Research and Markets, the global differential pressure market is projected to grow from $4.1 billion in 2021 to over $5.5 billion by 2026, indicating a compound annual growth rate (CAGR) of approximately 6.5%. This growth is largely attributable to increased automation in various sectors, particularly in oil and gas, pharmaceuticals, and water treatment.

Innovations such as wireless differential pressure sensors and IoT-enabled monitoring systems are transforming how businesses approach pressure measurement. These technologies not only provide real-time data analytics but also facilitate predictive maintenance, thereby reducing downtime and operational costs. A study published in the Journal of Industrial Instrumentation highlighted that companies adopting smart differential pressure solutions experience up to a 25% increase in operational efficiency. As these technologies continue to advance, industries are poised to benefit from enhanced performance and sustainability, reinforcing the critical role of differential pressure solutions in future growth strategies.

Related Posts

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

Challenges Encountered in Pulp and Paper Industry Operations

-

5 Essential Tips for Choosing the Right Liquid Filled Gauges

-

Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments