Why Precision Devices Are Essential for High-Quality Manufacturing Processes

In today’s competitive manufacturing landscape, precision devices have emerged as indispensable tools that significantly enhance production efficiency and product quality. According to a recent report by the International Society for Precision Engineering (ISPE), implementing precision devices can lead to a reduction in production errors by up to 30%, thus saving companies considerable resources and time. The rise of Industry 4.0 has further underscored the importance of these sophisticated instruments, as manufacturers strive to meet increasingly stringent quality standards while minimizing waste.

Expert insights also highlight the transformative impact of precision devices on manufacturing processes. Dr. Emily Chang, a leading authority in precision engineering, asserts, "Precision devices are not just tools; they are the foundation of excellence in manufacturing, enabling companies to achieve unparalleled accuracy and reliability." Her statement reflects the sentiment across the industry that investing in precision technology is pivotal in remaining competitive and meeting the evolving demands of consumers. As manufacturers embrace these essential devices, the potential for enhanced operational performance and improved product outcomes continues to grow.

The Role of Precision Devices in Reducing Manufacturing Tolerances by 10 Microns

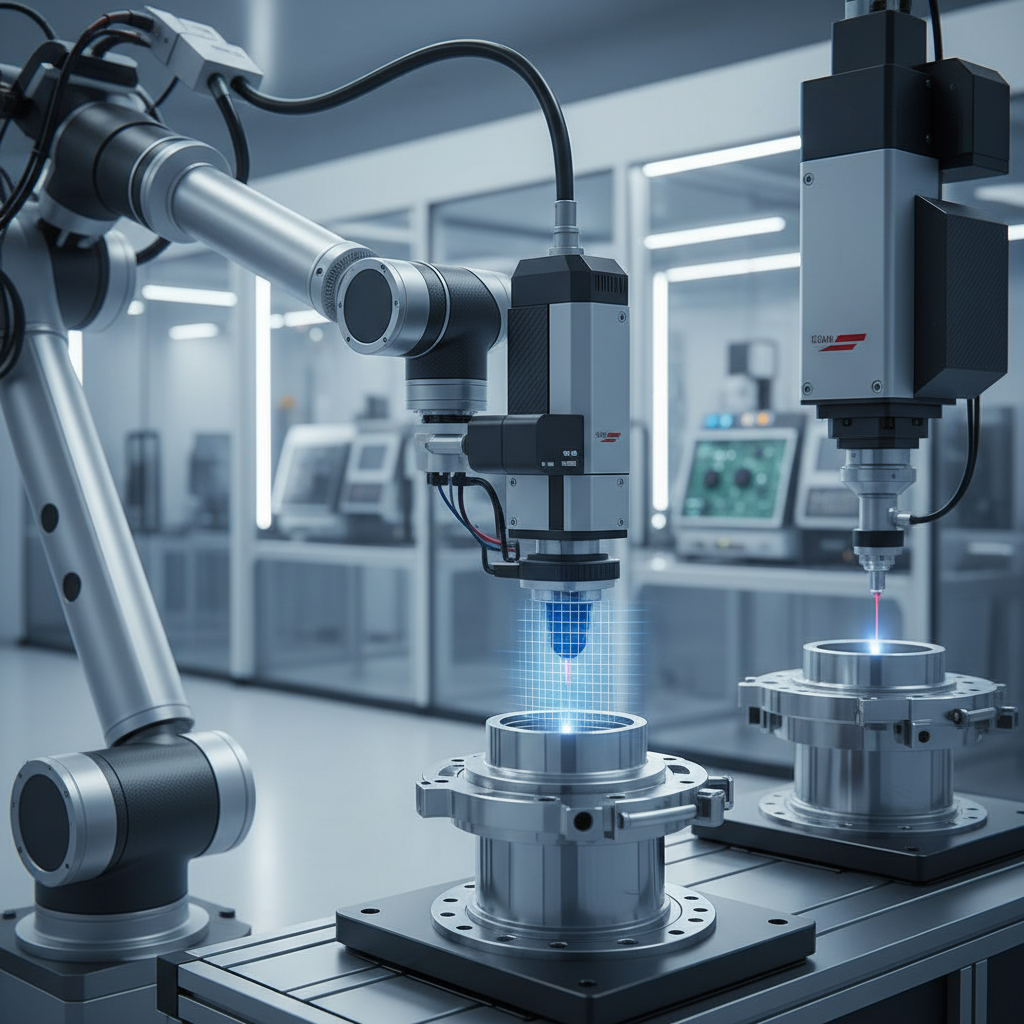

Precision devices play a critical role in high-quality manufacturing processes, particularly when it comes to reducing manufacturing tolerances to the exacting standard of 10 microns. In modern manufacturing environments where quality assurance is paramount, even the slightest deviation can lead to significant consequences in terms of product performance and reliability. Precision devices, such as CNC machines and laser measurement tools, ensure that each component is produced with exceptional accuracy, enabling manufacturers to achieve tight tolerances consistently.

By incorporating precision devices into their workflows, manufacturers can enhance their production capabilities and reduce waste. These advanced tools allow for real-time monitoring and adjustments, which help to maintain the integrity of the manufacturing process. For instance, the use of precision gauging systems can identify variances early in the production cycle, facilitating timely interventions and minimizing the potential for defects. As a result, manufacturers not only meet stringent quality standards but also improve operational efficiency, ultimately contributing to cost savings and increased competitiveness in the market.

Impact of Precision Measurement Technology on Product Quality Control

The impact of precision measurement technology on product quality control cannot be overstated, as it plays a pivotal role in ensuring that manufacturing processes meet stringent quality standards. By utilizing advanced precision devices, manufacturers can achieve meticulous measurements that significantly reduce errors in production. This is particularly crucial in industries such as aerospace, automotive, and electronics, where even the slightest deviation can compromise performance and safety. The integration of precision measurement technologies enables real-time monitoring of production processes, allowing for immediate adjustments to maintain optimal quality levels.

Furthermore, precision devices enhance the reliability of quality control measures by providing accurate data analytics. This data-driven approach facilitates better decision-making, guiding manufacturers in identifying defects early in the production cycle. When precision instruments are employed consistently, they contribute to reducing waste and minimizing rework, ultimately elevating overall efficiency. As precision measurement technology continues to evolve, its influence on product quality control will only deepen, reinforcing the importance of investing in these essential tools to secure a competitive edge in the manufacturing landscape.

Cost-Benefit Analysis: Investing in Precision Devices for Increased Efficiency

Investing in precision devices is crucial for manufacturers seeking to enhance efficiency and quality. The cost-benefit analysis of such investments reveals that while the initial expenditures may be substantial, the long-term gains in productivity and product quality can significantly offset these costs. For instance, the anticipated growth in sectors such as laser welding technology, projected to reach approximately $894 million by 2032, underscores the expanding demand for precision devices that boost manufacturing capabilities.

Tips: When considering an investment in precision devices, manufacturers should evaluate their specific production needs and the potential return on investment. Additionally, investing in training for skilled technicians can maximize the benefits of precision technology, ensuring that equipment is operated optimally.

Moreover, as precision farming technologies continue to evolve, it's essential to recognize that small landowners may face challenges in adopting these advancements. However, the increase in digital agriculture and the expected market growth in related sectors signal that accessibility to advanced farming devices is improving. By leveraging precision devices, manufacturers not only enhance their operational efficiency but also position themselves competitively in a rapidly growing market.

Impact of Precision Devices on Manufacturing Efficiency

Industry Standards: The Necessity of Precision Instruments in Aerospace Manufacturing

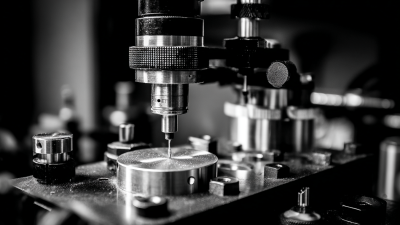

In aerospace manufacturing, the implementation of precision instruments is not just advantageous but critical for meeting stringent industry standards. According to a report by the Aerospace Industries Association, the aerospace sector is projected to reach $1 trillion by 2028, highlighting the increasing complexity and competitiveness of manufacturing processes. Precision devices play a vital role in ensuring that components meet the rigorous specifications required for safety and efficiency. For instance, tolerances as tight as ±0.001 inches are often mandated for critical components, necessitating the use of advanced measurement tools such as coordinate measuring machines (CMMs) and laser scanners.

Furthermore, the Federal Aviation Administration (FAA) emphasizes that non-compliance with manufacturing standards can lead to severe repercussions, including costly recalls and safety incidents. A study revealed that industries utilizing precision instruments witnessed a 30% reduction in defects, significantly enhancing overall product quality and safety. The integration of precision technology not only ensures adherence to regulations but also optimizes the manufacturing process, promoting a culture of excellence in aerospace production. This necessity for accuracy and reliability underscores the vital role that precision devices play in the industry's success.

Why Precision Devices Are Essential for High-Quality Manufacturing Processes

| Dimension | Precision Requirement | Impact on Manufacturing |

|---|---|---|

| Dimensional Accuracy | ±0.01 mm | Ensures parts fit together correctly, reducing assembly time. |

| Surface Finish Quality | Ra 0.8 µm | Improves lubrication and wear resistance, enhancing product lifespan. |

| Weight Tolerance | ±5 g | Ensures compliance with load specifications for performance optimization. |

| Thermal Expansion Coefficient | ≤ 10 x 10⁻⁶ /°C | Maintains dimensional stability under temperature fluctuations. |

| Electrical Conductivity | ≥ 60% IACS | Ensures reliable electrical performance in aerospace applications. |

Emerging Trends: How Precision Devices Drive Innovation in Smart Manufacturing Systems

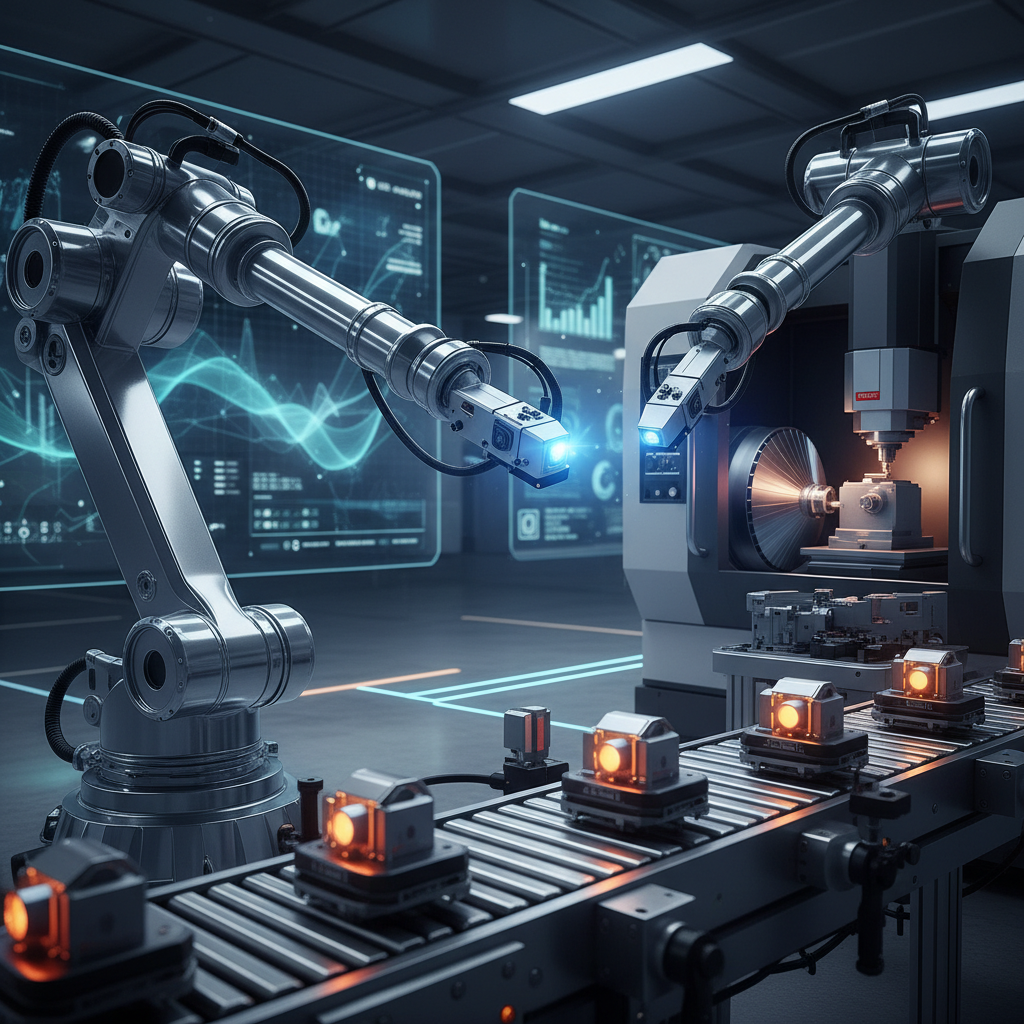

Emerging trends in smart manufacturing are increasingly reliant on

precision devices, which significantly enhance productivity and product quality.

These sophisticated tools, from high-accuracy CNC machines to advanced sensors, provide the necessary precision to meet the

rigorous demands of modern manufacturing. By integrating precision devices into their operations, manufacturers can minimize errors,

reduce waste, and optimize processes in real-time, thereby driving efficiency

and innovation.

Moreover, the rise of automation and the Internet of Things (IoT) has further underscored the

importance of precision technology. Smart manufacturing systems leverage data and machine learning to fine-tune production processes,

predicting potential issues before they arise. As these systems become more intricate, precision devices play a crucial role in maintaining

the integrity and reliability of operations. By facilitating seamless communication between machines and systems, they enable manufacturers

to adapt quickly to changing market dynamics and consumer needs, ultimately propelling the industry towards a more innovative future.

Related Posts

-

5 Compelling Reasons to Choose Precision Devices for Your Next Project

-

Navigating the Challenges of Precision Devices in Today's High Demand Markets

-

7 Essential Tips for Choosing Precision Instruments for Your Business Needs

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

-

The Ultimate Guide to Choosing the Right HVAC Gauges for Efficient System Maintenance

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments