Challenges Encountered in Pulp and Paper Industry Operations

The pulp and paper industry, a vital segment of the global economy, faces numerous operational challenges that impact its efficiency and sustainability. According to a report by Smithers Pira, the industry is projected to experience a compound annual growth rate (CAGR) of 2.4% from 2020 to 2025, underscoring its importance. However, this growth comes with significant hurdles, including the need for modernization of aging infrastructure, pressure to reduce environmental impacts, and the volatility of raw material prices. Additionally, the industry is confronted with regulatory challenges aimed at promoting sustainability and reducing carbon emissions. As companies strive to adapt to these demands, understanding and overcoming the challenges encountered in pulp and paper operations will be crucial for enhancing productivity and ensuring long-term viability in an increasingly competitive marketplace.

Digital Transformation Challenges in the Pulp and Paper Industry

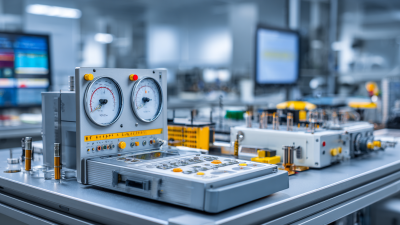

The pulp and paper industry is undergoing a significant digital transformation, yet this transition comes with a unique set of challenges. One of the primary hurdles is the integration of advanced technologies into legacy systems that have been in place for decades. Many companies struggle to replace old equipment, which often cannot support new software. This incompatibility can lead to inefficient operations, data silos, and missed opportunities for enhancing productivity through automation and real-time data analytics.

Additionally, the industry faces a skills gap as the workforce grapples with new technologies. Employees need training to operate advanced machinery and data analytics tools effectively. Resistance to change can also hinder progress, as some workers may prefer familiar processes over adopting new digital practices. Moreover, cybersecurity threats increase as operations become more interconnected, necessitating a robust framework to protect sensitive data. Effective management of these challenges is crucial for ensuring that digital transformation efforts yield the desired improvements in efficiency, sustainability, and overall competitiveness in the pulp and paper sector.

Challenges Encountered in Pulp and Paper Industry Operations

Reasons for Inefficiencies in Pulp and Paper Operations

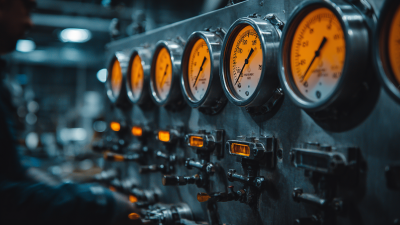

In the pulp and paper industry, inefficiencies can arise from various sources, impacting overall productivity and profitability. One significant reason for these inefficiencies is outdated machinery. Many facilities still rely on legacy equipment that lacks the technological advancements found in modern alternatives. This leads to higher maintenance costs and frequent downtimes, disrupting the production flow.

To mitigate this issue, it is essential for operations managers to invest in upgrading machinery and embracing automation technologies. Implementing predictive maintenance can also help in identifying potential failures before they occur, thus minimizing unforeseen downtimes.

Another contributing factor to inefficiencies is the lack of skilled labor. As the industry evolves, the demand for workers with advanced technical skills increases. Training programs that focus on current technologies and practices can help bridge this gap.

Furthermore, fostering a culture of continuous improvement encourages employees to identify and address inefficiencies proactively. Regular feedback sessions can empower staff to contribute ideas for process optimization, ultimately leading to enhanced operational efficiency.

Challenges Encountered in Pulp and Paper Industry Operations - Reasons for Inefficiencies in Pulp and Paper Operations

| Challenge | Reason for Inefficiency | Impact Level (1-5) | Potential Solutions |

|---|---|---|---|

| High Energy Consumption | Outdated machinery and processes | 5 | Invest in energy-efficient technologies |

| Water Waste | Inefficient water recycling systems | 4 | Enhance recycling systems and practices |

| Raw Material Quality | Inconsistent sourcing of wood fibers | 4 | Establish reliable supplier contracts |

| Labor Shortages | Technological skill gaps among workers | 3 | Training and workforce development programs |

| Environmental Regulations | Complex compliance processes | 5 | Implement compliance management software |

Impact of Environmental Regulations on Industry Performance

The pulp and paper industry has faced increasing pressure from environmental regulations that aim to mitigate its environmental footprint. These regulations often focus on reducing emissions, managing waste, and ensuring sustainable forestry practices. As the industry adapts to these requirements, companies find themselves navigating a complex landscape of compliance that varies by region and is influenced by public sentiment and scientific advancements. This necessitates investments in new technologies and processes, thus impacting operational efficiencies and overall production costs.

Moreover, stringent regulations can also drive innovation within the industry. Companies that embrace sustainable practices not only improve their compliance status but also enhance their brand image, appealing to environmentally conscious consumers. However, the transition to greener alternatives can be challenging. Some operators struggle to balance the costs of implementation with the potential for reduced profitability. As they strive to meet both regulatory demands and market expectations, the pulp and paper industry is forced to evolve, adopting cleaner production methods that promise long-term sustainability. The ability to adapt to these environmental regulations will ultimately determine the industry's resilience and growth in an increasingly eco-conscious market.

Technological Adoption Barriers in the Pulp and Paper Sector

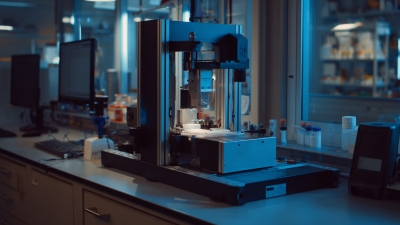

The pulp and paper industry is facing significant challenges in adopting new technologies that could streamline operations and increase efficiency. One major barrier is the high initial investment required for advanced machinery and software. Many companies, particularly smaller ones, struggle to allocate sufficient funds for these upgrades, leading to stagnation in operational improvements. Additionally, there can be a lack of skilled workforce trained in the latest technologies, making it difficult for companies to implement and maintain new systems effectively.

To navigate these challenges, businesses should consider a gradual approach to technological adoption. Start by identifying specific areas within operations that could benefit from automation or digital solutions. Investing in training programs for existing employees can also bridge the skills gap, ensuring your team is equipped to handle new tools and technologies.

Another tip is to seek partnerships with technology providers who offer flexible financing options or tailored solutions suited to your operational size and needs. This can alleviate some financial pressure and make the transition to modern practices more manageable, allowing for a smoother integration of technology into the company’s workflow.

Workforce Skill Gaps in Modern Pulp and Paper Production

The pulp and paper industry is facing significant challenges, particularly when it comes to workforce skill gaps. As technology advances, the need for employees who can operate modern machinery and understand complex processes has never been more crucial. Many existing workers may find themselves lacking the necessary skills, leading to inefficiencies and reduced productivity. This gap not only affects day-to-day operations but also impacts the industry's ability to innovate and remain competitive in a rapidly changing market.

To address these workforce skill gaps, companies should consider implementing targeted training programs that focus on the latest technologies and best practices. Investing in professional development can help ensure that workers are equipped to handle modern production techniques. Additionally, pairing experienced employees with newer staff in mentorship programs can facilitate knowledge transfer and build a more skilled workforce.

Another effective strategy is to collaborate with educational institutions to create curricula that align with industry needs. By providing students with practical experience and knowledge about the pulp and paper industry, companies can cultivate a new generation of skilled professionals ready to meet the demands of the field. Such partnerships can also help foster innovation and ensure the long-term sustainability of operations.

Related Posts

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

The Ultimate Guide to Choosing the Perfect Digital Manometer for Your Needs

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments