Essential Refrigeration Gauges Tips for Accurate HVAC Diagnostics

In the realm of HVAC diagnostics, accurate measurements are paramount, and refrigeration gauges play a pivotal role in ensuring system efficiency and reliability. According to a recent report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper gauge readings can lead to significant errors in diagnosing system issues, impacting both performance and energy consumption. This underscores the importance of understanding and utilizing refrigeration gauges effectively.

Expert insights further illuminate the significance of precision in this domain. Dr. Stephen L. Becker, a leading voice in HVAC technology, once stated, "The accuracy of refrigeration gauges is not just about reading numbers; it's about ensuring the longevity and efficiency of HVAC systems." His perspective resonates with many industry professionals, emphasizing that the ability to interpret these gauges correctly can drastically influence maintenance approaches and repair strategies.

As HVAC systems continue to grow in complexity, the need for reliable diagnostic tools like refrigeration gauges becomes even more critical. By adhering to best practices and staying informed about the latest developments in this area, technicians can enhance their diagnostic capabilities, ultimately leading to improved service quality and customer satisfaction.

Understanding the Basics of Refrigeration Gauges in HVAC Systems

Refrigeration gauges are vital tools for HVAC technicians, providing crucial data for diagnostics and system performance assessment. Understanding the basics of these gauges is essential for accurate measurements and timely maintenance. Two primary types of gauges—manifold gauges and digital gauges—offer varying levels of detail. According to the U.S. Department of Energy, improper refrigerant levels can lead to energy inefficiency, increasing operational costs by up to 30%. Hence, using the right gauge accurately to read pressures is fundamental in reducing energy consumption and prolonging system life.

Tip 1: Always check for proper calibration before using your gauges. This ensures that the readings you obtain are accurate, reducing the risk of errors that can lead to further complications in HVAC systems. Calibration checks should be done according to manufacturer guidelines or at least annually, especially in professional settings.

Tip 2: Familiarize yourself with the pressure-temperature relationship of the refrigerants used in your system. For instance, R-410A operates at higher pressures compared to R-22. Understanding these differences is crucial for diagnosing issues accurately. Moreover, a study from the Air Conditioning, Heating, and Refrigeration Institute (AHRI) indicates that up to 50% of HVAC breakdowns can be traced back to refrigerant issues, highlighting the importance of thorough pressure checks.

By leveraging refrigeration gauges effectively, HVAC professionals can ensure efficient system operation and minimize the risk of costly repairs.

Essential Refrigeration Gauges Performance

This chart illustrates the performance levels of various refrigeration gauges used in HVAC diagnostics, showcasing their accuracy temperature ranges in Fahrenheit.

Choosing the Right Refrigeration Gauges for Accurate Diagnostics

Choosing the right refrigeration gauges is crucial for achieving accurate diagnostics in HVAC systems. When selecting gauges, professionals should consider both analog and digital options.

Analog gauges, while often favored for their straightforward design, can be prone to errors if not frequently calibrated. On the other hand, digital gauges provide precise readings and often come equipped with additional features such as data logging and built-in temperature compensation. Each type has its advantages, and the choice largely depends on the specific needs of the HVAC technician.

Compatibility is another essential factor when choosing refrigeration gauges. Technicians should ensure that the gauges are suitable for the refrigerants being used in the systems they service. Specific gauges are designed for high-pressure systems, while others can accurately measure low-pressure environments.

Additionally, features such as color-coded scales and dual-pressure readings help technicians quickly interpret data, enhancing the efficiency of diagnostics. Prioritizing these characteristics will not only lead to better system evaluations but also contribute to overall service quality.

Interpreting Pressure Readings: A Step-by-Step Guide

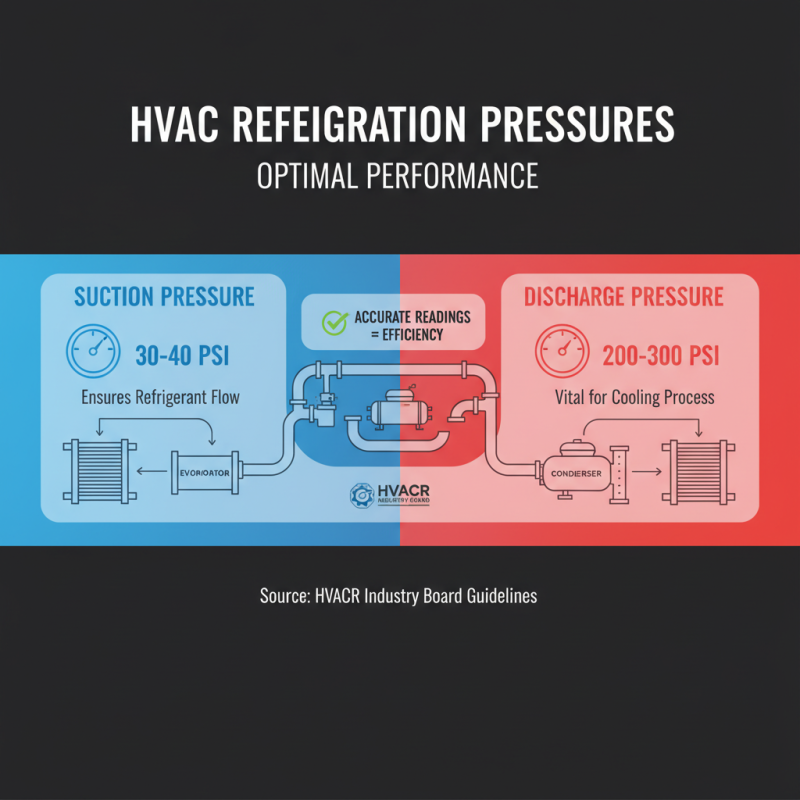

Interpreting pressure readings is crucial in HVAC diagnostics, as accurate measurements can significantly affect the performance and efficiency of refrigeration systems. When assessing the system, one must first understand the basics of pressure readings—suction pressure and discharge pressure—commonly measured in psi (pounds per square inch). According to the HVACR Industry Board, maintaining appropriate pressure levels can ensure optimal refrigerant flow, which is vital for the cooling process. Typically, a standard refrigeration system operates with suction pressures between 30 to 40 psi, while discharge pressures range from 200 to 300 psi, depending on the system design and environmental conditions.

When taking pressure readings, it's essential to ensure that your gauges are calibrated correctly. Outdated or miscalibrated gauges can yield misleading results, leading technicians to make incorrect conclusions about system performance. For accurate diagnostics, always check the gauge connections for leaks and ensure that your hose connections are tight before taking measurements. Remember, the ambient temperature plays a significant role in pressure readings; for instance, higher ambient temperatures can cause higher pressure readings.

Tip: Before interpreting the readings, always compare them against manufacturer specifications, as data can vary significantly based on the specific refrigerant used. Additionally, if the pressure readings deviate from typical ranges, it might indicate issues such as overcharging or undercharging of the refrigerant, or even potential system blockages. Keeping a close watch on these readings helps maintain system integrity and extends the equipment's lifespan.

Common Mistakes When Using Refrigeration Gauges and How to Avoid Them

When using refrigeration gauges for HVAC diagnostics, several common mistakes can lead to inaccurate readings and misdiagnosis. One of the most prevalent errors is not properly zeroing the gauge before use. This step is crucial, as any residual pressure can skew the measurements, resulting in a faulty assessment of the system’s performance. Technicians should always ensure that gauges are calibrated and functioning correctly, taking a moment to check for any discrepancies before attaching them to the system.

Another frequent oversight is neglecting to differentiate between the high and low-pressure sides of the system. Many technicians may inadvertently connect the gauges incorrectly, leading to incorrect evaluations. Understanding the layout of the HVAC system and using colored hoses or labeling can help mitigate these errors. Additionally, it’s vital to monitor the ambient conditions, as extreme temperatures might affect the pressure readings; two technicians with different work environments might interpret the same gauge readings differently. By recognizing these pitfalls and adhering to best practices, HVAC professionals can enhance their diagnostic accuracy and overall efficiency.

Maintaining Refrigeration Gauges for Long-Term Accuracy and Reliability

Maintaining refrigeration gauges is crucial for ensuring long-term accuracy and reliability in HVAC diagnostics. According to the HVACR Workforce Development Foundation, approximately 30% of HVAC technicians report issues related to inaccurate pressure readings throughout their careers. This highlights the need for regular maintenance of refrigeration gauges to avert errors that can lead to inefficiencies in system operations.

One essential tip for maintaining refrigeration gauges is to routinely check for leaks and inspect seals. Leaky gauges can not only provide false readings but also lead to potentially hazardous situations. Technicians should apply a suitable leak detection solution to the gauge fittings, and if bubbles form, immediate action should be taken to replace seals or fittings. Additionally, storing gauges in protective cases when not in use can prevent physical damage that could compromise their accuracy.

Another critical practice is to calibrate gauges periodically against known standards. A survey by the North American Technician Excellence (NATE) shows that improperly calibrated gauges can lead to errors of up to 5% in pressure readings, significantly impacting diagnostic accuracy. Schedule a calibration at least once a year or whenever gauges are suspected of being off, ensuring that they provide reliable data for more effective troubleshooting and increased system longevity.

Related Posts

-

7 Essential Tips for Choosing the Best Refrigeration Gauges for Your Needs

-

7 Essential Tips for Choosing the Right Refrigeration Gauges to Boost Efficiency by 30%

-

2025 How to Choose the Best Refrigeration Gauges for Your Needs

-

How to Optimize Your System Using Differential Pressure Measurements

-

What Are Digital Gauges and How Do They Revolutionize Modern Measurement?

-

Exploring Marsh Gauges Innovations at the 138th Canton Fair China 2025

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments