Top Strategies for Utilizing Digital Gauges in HVAC Efficiency

In the ever-evolving landscape of HVAC efficiency, the integration of digital gauges HVAC has emerged as a pivotal strategy for optimizing performance and reducing energy consumption. According to the U.S. Department of Energy, approximately 30% of energy used in buildings is wasted due to inefficient HVAC systems. By implementing digital gauges, technicians can achieve precise measurements of pressure and temperature, leading to improved system diagnostics and enhanced operational efficiency. A study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlights that utilizing advanced measurement tools can not only prolong equipment lifespan but also reduce energy costs by up to 20%. As HVAC professionals seek to navigate the complexities of modern systems, embracing the capabilities of digital gauges becomes essential for achieving maximum efficiency and sustainability.

Understanding Digital Gauges and Their Role in HVAC Efficiency

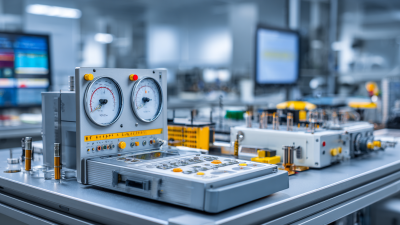

Digital gauges have become an integral part of enhancing HVAC efficiency, providing precise measurements that contribute to better system performance. These modern instruments allow technicians to monitor temperature, pressure, and humidity levels in real-time, ensuring that HVAC systems operate within optimal parameters. With their digital displays and advanced features, these gauges facilitate quick decision-making, which can significantly reduce response times during maintenance and troubleshooting.

Understanding their role in HVAC efficiency involves recognizing the benefits of accurate data collection. Digital gauges minimize human error often associated with analog devices, ensuring that the information obtained is accurate and reliable. This accuracy leads to more informed operational adjustments, ultimately improving energy efficiency and extending equipment lifespan. Moreover, integrating these gauges into a building management system can streamline operations and enhance overall indoor air quality, making digital gauges an essential tool for anyone looking to optimize HVAC performance.

Key Benefits of Integrating Digital Gauges into HVAC Systems

Integrating digital gauges into HVAC systems presents several key benefits that significantly enhance efficiency and performance. One of the most prominent advantages is the real-time data monitoring capabilities that these gauges offer. By providing instant feedback on temperature, pressure, and humidity levels, technicians can make informed decisions quickly, ensuring that the system operates at optimal levels. This continuous monitoring helps identify inefficiencies and allows for prompt adjustments, which can lead to substantial cost savings in energy consumption and maintenance.

Moreover, digital gauges contribute to improved accuracy in diagnostics and troubleshooting. Traditional analog gauges can often be subject to human error and misinterpretation, while digital gauges provide precise readings that enhance the technician's ability to pinpoint issues accurately. This level of precision not only facilitates quicker repairs but also prolongs the lifespan of HVAC systems by preventing unnecessary strain caused by undetected problems. Ultimately, the integration of digital gauges transforms HVAC maintenance from a reactive to a proactive approach, ensuring efficient operation and reliability in all seasons.

Impact of Digital Gauges on HVAC Efficiency

Best Practices for Implementing Digital Gauges in HVAC Applications

The implementation of digital gauges in HVAC applications can significantly enhance energy efficiency and overall performance. According to various industry reports, HVAC systems account for nearly 40% of energy consumption in commercial buildings, underscoring the critical need for efficient management strategies. Digital gauges provide real-time data that enable precise monitoring of system performance, allowing facilities to identify inefficiencies rapidly. This immediate feedback loop not only helps in reducing operational costs but also contributes to maintaining optimal indoor environmental conditions for occupants.

Furthermore, the integration of IoT-enabled climate-control technologies is transforming healthcare environments. A recent study highlights that healthcare organizations adopting these advanced systems have reported energy savings of up to 30%, while also improving patient comfort and safety. By employing digital gauges, HVAC technicians can better utilize machine learning algorithms to predict maintenance needs and optimize energy use, aligning with broader initiatives for smart building design. With the growing emphasis on sustainability and smart environments, adopting best practices for digital gauge implementation stands to play a pivotal role in achieving these ambitious energy goals.

Top Strategies for Utilizing Digital Gauges in HVAC Efficiency - Best Practices for Implementing Digital Gauges in HVAC Applications

| Strategy | Benefit | Implementation Steps | Expected Outcome |

|---|---|---|---|

| Real-Time Monitoring | Improved response times to system issues | Install digital gauges at key points; integrate with a monitoring system | Reduction in downtime and maintenance costs |

| Data Logging | Historical data for performance analysis | Set up data logging features; ensure regular backups | Enhanced troubleshooting and operational efficiency |

| Calibration Checks | Ensures accurate readings | Schedule regular calibration; use certified tools | Increased trust in performance data |

| User Training | Enhances the effectiveness of gauge use | Create a training program; involve hands-on demonstrations | Better operation and maintenance practices |

| Integrate with BMS | Improves centralized control | Connect gauges to Building Management System; ensure compatibility | Streamlined operations and energy savings |

Real-time Data and Its Impact on HVAC Performance Optimization

Real-time data has revolutionized the way HVAC systems are monitored and managed. By utilizing digital gauges, HVAC professionals can access immediate performance metrics, enabling them to identify inefficiencies swiftly. This access to live data allows for proactive management of HVAC systems, ensuring that any deviations from optimal performance are addressed before they escalate into costly issues. For instance, if a digital gauge indicates fluctuating temperatures within a zone, technicians can investigate the root cause, whether it's a failing component or a need for system recalibration.

Moreover, the integration of real-time data analytics enhances decision-making processes. By analyzing trends over time, HVAC operators can not only optimize current performance but also forecast future needs and plan maintenance schedules more effectively. This predictive capability minimizes downtime, extends equipment lifespan, and ultimately leads to significant energy savings. Utilizing digital gauges in HVAC systems is no longer just a trend; it is a strategic approach to achieving peak performance and sustainability in energy use.

Troubleshooting Common Issues with Digital Gauges in HVAC Systems

In the realm of HVAC systems, digital gauges have become indispensable tools for both efficiency monitoring and troubleshooting. However, even the most advanced digital gauges can present challenges when troubleshooting common issues. One prevalent issue arises from high temperatures, which can lead to increased pressure readings that may mislead technicians. In such cases, understanding how to interpret these readings accurately is critical. Properly calibrated gauges can help identify if the problem lies within the system itself or if it's merely a response to environmental conditions.

Another common concern is the potential for coil complications, such as plugging or freeze-ups, which can severely affect HVAC performance. Digital gauges can aid in diagnosing these issues by providing real-time data on pressure and temperature, allowing technicians to pinpoint the root cause of the malfunction. Knowing how to use digital gauges effectively can significantly streamline the troubleshooting process, reducing service time and improving overall system reliability. Technicians should also ensure that their digital tools are regularly maintained and verified for accuracy to prevent erroneous readings that could lead to unnecessary repairs.

Related Posts

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

7 Surprising Benefits of Liquid Filled Pressure Gauges for Your Industry

-

5 Essential Tips for Choosing the Right Liquid Filled Gauges

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

Top Strategies for Maximizing Efficiency with Differential Pressure Solutions

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments