Essential Tips for Choosing Pressure Gauges for Water Systems?

Choosing the right pressure gauges for water systems is crucial. These instruments help ensure accurate readings and system efficiency. A reliable gauge can prevent leaks and save costs.

When selecting pressure gauges for water, consider the environment. Factors such as temperature and humidity can impact performance. Some gauges may not perform well under extreme conditions. This could lead to inaccurate measurements.

Another important aspect is the gauge's materials. Corrosion resistance is essential in water systems. Subpar materials can lead to failures over time. It's also vital to understand the pressure range needed for your system. Oversized or undersized gauges may create problems. Thus, taking the time to select appropriate pressure gauges for water systems is important for long-term success.

Essential Factors to Consider When Selecting Pressure Gauges for Water Systems

When selecting pressure gauges for water systems, several essential factors come into play. Accuracy is vital. A gauge that provides incorrect readings can lead to catastrophic failures. Always check the accuracy rating. Is it sufficient for your application's requirements?

Material selection is another critical factor. Pressure gauges can be made from various materials. Stainless steel and brass are popular options. However, consider the water's characteristics. Will there be contaminants? Corrosive substances might degrade some materials, affecting performance.

Pressure range is also important. Too high or too low can result in damage or inaccurate readings. Evaluate your system's maximum and minimum pressure. What are the operating conditions? Take time to assess these aspects carefully. Ignoring them might lead to costly mistakes.

Understanding Measurement Units: PSI, Bar, and Other Standards in Water Systems

Choosing the right pressure gauge for water systems requires a solid understanding of measurement units such as PSI and Bar. PSI stands for pounds per square inch and is widely used in the United States. It is vital for monitoring water pressure in various applications. For instance, a typical residential water system operates between 40 and 60 PSI. Choosing a gauge that accurately measures this range helps in maintaining optimal performance.

On the other hand, Bar is the standard unit in many other countries. One Bar equals approximately 14.5 PSI. Understanding this conversion is essential. In industrial settings, pressures can reach much higher levels. Reports suggest that some systems operate at 4 to 10 Bar, which is crucial for proper functioning. Yet, confusion often arises with these units, causing performance issues.

Consider the environment where the gauge will be used. Factors like temperature and humidity can affect accuracy. Not all gauges withstand extreme conditions. Some may offer a lower range of tolerance. Therefore, choosing a gauge that fits specific needs is critical. An ill-suited pressure gauge can lead to misreading, potentially harming the system. Balancing accuracy and environmental resilience is a common challenge for operators.

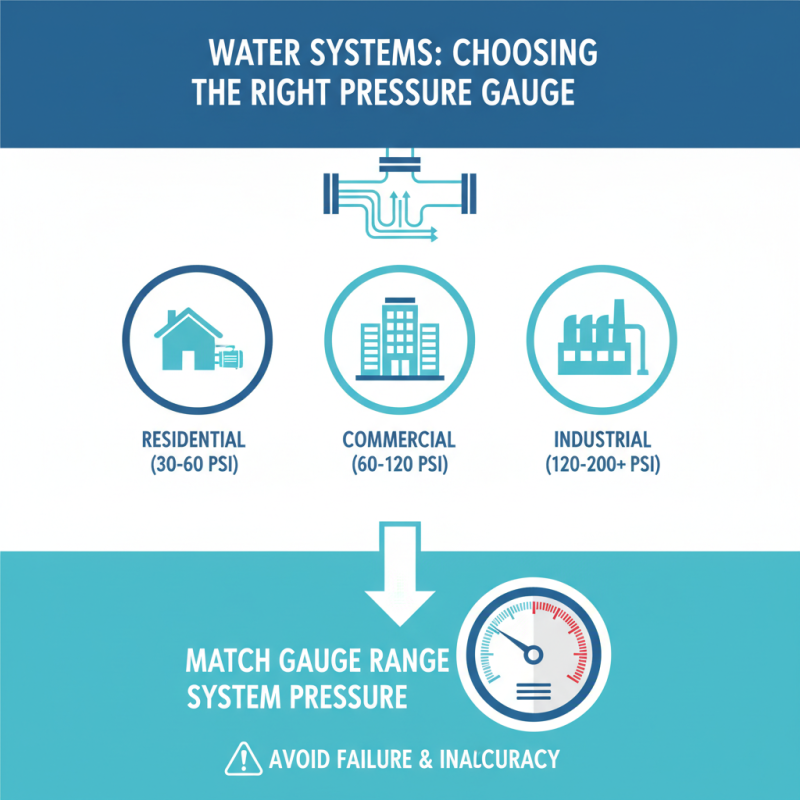

Determining the Appropriate Pressure Range for Specific Water Applications

Choosing the right pressure gauge for water systems is crucial. One key factor to consider is the pressure range required for your specific application. Different water systems operate under various pressure conditions. A gauge that cannot handle the system's maximum pressure may fail or produce inaccurate readings.

When determining the appropriate pressure range, consider the maximum and minimum pressure levels. Water supply systems typically operate between 30 to 80 psi. However, irrigation systems may require lower pressure settings. It's essential to match the gauge to the system's needs. Oversized gauges may read incorrectly, making monitoring difficult.

Here are some tips to streamline your selection process. Look for gauges that offer clear markings. Accurate reading ensures you're always aware of your system's state. Additionally, consider the application environment. If the gauge will face extreme conditions, choose a durable design. Don't forget to verify that the range you select covers all potential pressure fluctuations. This step will save you from frequent replacements or adjustments.

Evaluating Accuracy and Precision: Importance of Calibration in Pressure Gauges

When selecting pressure gauges for water systems, calibration is crucial. Proper calibration ensures that the gauge measures accurately and provides reliable data. Without it, readings can be misleading. This could lead to significant issues in water management. Mistakes in measurements can cause equipment failures or inefficient systems.

Accuracy and precision are not always synonymous. A gauge might read consistently but may not be correct. Regular calibration helps to maintain both accuracy and precision. It’s important to periodically check gauges against known standards. This practice can reveal discrepancies that require attention.

Ignoring calibration can result in costly errors. Users might trust faulty readings without realizing the issue. Sometimes, equipments run under unrealistic pressures. Regular maintenance and checks can prevent this. It’s not just about choosing a gauge; it’s about ensuring it performs well over time.

Essential Tips for Choosing Pressure Gauges for Water Systems: Evaluating Accuracy and Precision

| Gauge Type | Accuracy Range | Calibration Frequency | Maximum Pressure | Connection Type |

|---|---|---|---|---|

| Digital Pressure Gauge | ±0.5% Full Scale | Annually | 300 PSI | 1/4" NPT |

| Mechanical Pressure Gauge | ±1.0% Full Scale | Every 6 months | 150 PSI | 1/2" Flare |

| Bourdon Tube Gauge | ±2.0% Full Scale | Every 12 months | 600 PSI | 1/4" NPT |

| Digital Smart Gauge | ±0.25% Full Scale | Quarterly | 1000 PSI | 1/4" BSP |

| Electronic Pressure Transducer | ±0.5% Full Scale | Annually | 1500 PSI | 1/2" NPT |

Material Selection: Choosing the Right Components for Corrosive Water Environments

When selecting pressure gauges for water systems, material selection is crucial. Corrosive environments pose unique challenges. Standard materials may degrade quickly, leading to inaccurate readings and safety concerns. Choosing the right components can extend the gauge's lifespan and reliability.

Stainless steel is a popular choice, known for its durability. However, it's vital to consider the specific corrosive elements in your water. Some stainless steel grades resist certain acids better than others. Also, plastic can be a viable option for less aggressive environments. It’s lightweight, but you must ensure it meets your system’s requirements.

Tips: Always review the environmental conditions before making a decision. Consult data sheets for material compatibility. Sometimes, even minor adjustments can lead to significant improvements. A little research can save time and resources. Making decisions based on incomplete information can lead to failures. Look beyond just price; quality matters significantly in critical applications.

Related Posts

-

Understanding Pressure Gauges for Water: Key Metrics and Their Importance in Fluid Management

-

Essential Checklist for Choosing the Right Digital Pressure Gauges

-

7 Essential Low Pressure Gauges You Need for Accurate Measurements

-

7 Surprising Benefits of Liquid Filled Pressure Gauges for Your Industry

-

7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

-

What are Marsh Pressure Gauges and Their Critical Role in Industrial Applications?

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments