Essential Tips for Using Digital Gauges in HVAC Systems?

Using digital gauges in HVAC systems can greatly improve efficiency and accuracy. These tools provide real-time data, helping technicians make informed decisions. With the right techniques and understanding, you can maximize their benefits.

Digital gauges HVAC enhance diagnostics by offering precise readings. It's essential to understand calibration and settings, as improper use can lead to errors. Familiarize yourself with the display features and connection methods to avoid common pitfalls.

While these gauges are user-friendly, mistakes can happen. Technicians should not overlook regular maintenance for accuracy. Remember, experience often reveals gaps in knowledge. Embrace continuous learning for better results with digital gauges HVAC in your work.

Understanding the Basics of Digital Gauges in HVAC Systems

Digital gauges are vital tools in HVAC systems. They measure pressure, temperature, and flow with great precision. Understanding how these gauges work is essential for any technician. Familiarity ensures accurate readings, which is crucial for system performance.

When using digital gauges, pay attention to calibration. A gauge that isn't calibrated correctly can provide erroneous data. Regular checks are necessary. Be sure to verify readings against known standards. This simple step can save time and prevent costly mistakes.

Also, consider the environment where the gauges are used. Extreme temperatures or humidity can affect performance. Sometimes, a gauge may display erratic results due to external factors. If issues arise, don't rush to conclusions. Reflect on the conditions before making diagnoses. Troubleshooting requires patience and attention to detail.

Performance Metrics of HVAC Systems Using Digital Gauges

This bar chart illustrates the performance metrics of HVAC systems as measured by digital gauges. The values reflect different parameters such as temperature, pressure, and humidity across various systems over a typical operational period.

Key Features of Digital Gauges for Effective HVAC Monitoring

Digital gauges play a vital role in HVAC systems. Their accuracy and efficiency can directly impact system performance. Key features should be at the forefront when selecting these tools. Look for gauges that offer real-time readings. Instant updates can make a significant difference during troubleshooting.

Another important feature is durability. HVAC environments can be harsh. A good digital gauge should withstand temperature fluctuations and moisture. It should also have a protective casing. This protects it from accidental drops. A gauge that fails due to a fall can lead to inaccurate readings and mistakes.

When using digital gauges, consider the display quality. A clear, backlit screen aids visibility in dim environments. Quick-reading is important in the field. Regularly check battery levels, as a weak battery can skew results. Remember, relying on a faulty gauge could result in costly repairs later. Investing in quality tools pays off in the long run.

Essential Tips for Using Digital Gauges in HVAC Systems

| Feature | Description | Benefits | Recommended Usage |

|---|---|---|---|

| Digital Display | High-contrast LCD or LED screen showing real-time measurements. | Easier to read than analog gauges, even in low-light conditions. | Ideal for environments where visibility is a challenge. |

| Bluetooth Connectivity | Allows data transfer to smartphones or tablets for remote monitoring. | Streamlines data collection and analysis, reducing manual tracking. | Useful for HVAC professionals needing to analyze data off-site. |

| Multi-Parameter Measurement | Measures pressure, temperature, and flow rate simultaneously. | Provides comprehensive diagnostics for HVAC systems. | Enhances troubleshooting capabilities during maintenance. |

| Data Logging Functionality | Records measurements over time for longitudinal analysis. | Facilitates performance monitoring and trend identification. | Ideal for assessing system efficiency over extended periods. |

| Calibration Alert | Notifies user when calibration is needed based on usage patterns. | Ensures accuracy of readings to maintain system integrity. | Essential for maintaining high standards in HVAC monitoring. |

How to Properly Calibrate Digital Gauges in HVAC Applications

Calibrating digital gauges in HVAC applications is crucial for accurate readings. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that improper calibration can lead to efficiency losses of up to 20%. Accurate gauges help technicians optimize system performance. They provide essential data for troubleshooting issues.

Start by checking the gauge against a known standard. Use a calibration device that meets industry specifications. This ensures that your readings are reliable. If the gauge is off by even a small margin, it can affect the entire system. According to recent reports, nearly 35% of HVAC failures could be traced back to improperly calibrated instruments. Ignoring this can be costly for both systems and businesses.

When calibrating, consider environmental factors. Temperature changes can impact readings. Always allow your gauges to acclimate to the work environment. Regular maintenance is also essential, yet often overlooked. A simple inspection can prevent significant errors. Being diligent in calibration practices reinforces overall system reliability. However, many technicians still overlook this necessity. Reflecting on proper calibration may lead to greater efficiency in HVAC services.

Tips for Troubleshooting Common Issues with Digital Gauges

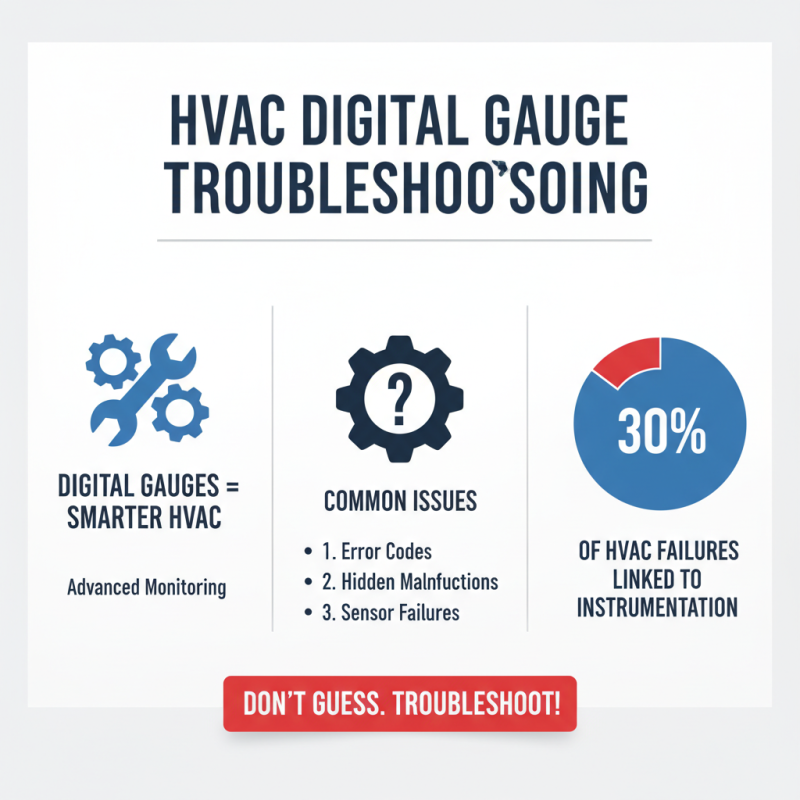

When working with digital gauges in HVAC systems, troubleshooting often becomes necessary. Digital gauges can display errors that may not be immediately obvious. Research indicates that around 30% of HVAC failures are linked to instrumentation issues. This highlights the importance of thorough troubleshooting.

One common issue is inaccurate readings. This can be caused by poor sensor placement or obstruction. Ensure that sensors are not near heat sources or airflow disturbance. Regular calibration is also essential. A study shows that 15% of digital gauges drift out of calibration over time. This drift can lead to significant evaluation errors in system performance.

Another frequent problem is battery failure. Digital gauges often rely on batteries for power, and a dying battery can cause inconsistent performance. Check the battery level regularly, and keep replacements on hand. Regular maintenance checks combined with a proactive approach can enhance the reliability of readings. Remember, all digital gauges require attention and care to ensure they operate optimally.

Best Practices for Maintaining Digital Gauges in HVAC Systems

Using digital gauges in HVAC systems can enhance efficiency. However, maintaining these tools is just as important to ensure accuracy. Regular checks and simple care can help them last longer.

Start by cleaning the gauges regularly. Dust and dirt can interfere with their accuracy. Use a soft cloth to wipe away any debris. This simple action prevents potential readings errors. Calibration is equally crucial. Periodically, gauges should be tested for accuracy. This ensures they measure pressure and temperature correctly.

Another tip: store your digital gauges properly. Keep them away from extreme temperatures and humidity. Protecting them from physical damage is key. Make tools easily accessible to encourage regular use. Think about how you handle them daily. Mistakes happen, but learning from them is essential. Reflect on past experiences with your tools. Adjust your practices as needed. Knowing your equipment well contributes to more reliable HVAC system management.

Related Posts

-

What Are Digital Gauges and How Do They Revolutionize Modern Measurement?

-

What are Digital Gauges for HVAC and How Do They Improve Efficiency

-

Top Strategies for Utilizing Digital Gauges in HVAC Efficiency

-

Exploring the Future of Digital Gauges at the 138th Canton Fair in 2025

-

10 Essential Tips for Choosing the Right Digital Gauges for Your Needs

-

The Ultimate Guide to Choosing Digital Gauges for HVAC Systems

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments