2025 Top HVAC Gauges Guide for Efficient Temperature and Pressure Measurements

In the evolving landscape of HVAC technology, precise temperature and pressure measurements are crucial for optimal system performance. As industry expert, James Thompson, a renowned HVAC technician, once stated, "Accurate readings from HVAC gauges not only enhance efficiency but also extend the lifespan of heating and cooling systems." This insight underscores the importance of selecting the right tools for HVAC professionals, especially when it comes to gauges that measure vital system parameters.

In 2025, the market for HVAC gauges is set to expand, with innovations aimed at improving user experience and accuracy. Whether for troubleshooting, routine maintenance, or system installation, having the best HVAC gauges at your fingertips can significantly impact operational efficiency and effectiveness. This guide delves into the top options available, examining features, functionalities, and the overall impact these instruments have on achieving superior HVAC performance. As technology advances, ensuring that you have the right HVAC gauges will be central to meeting both industry standards and customer expectations.

Introduction to HVAC Gauges and Their Importance in the Industry

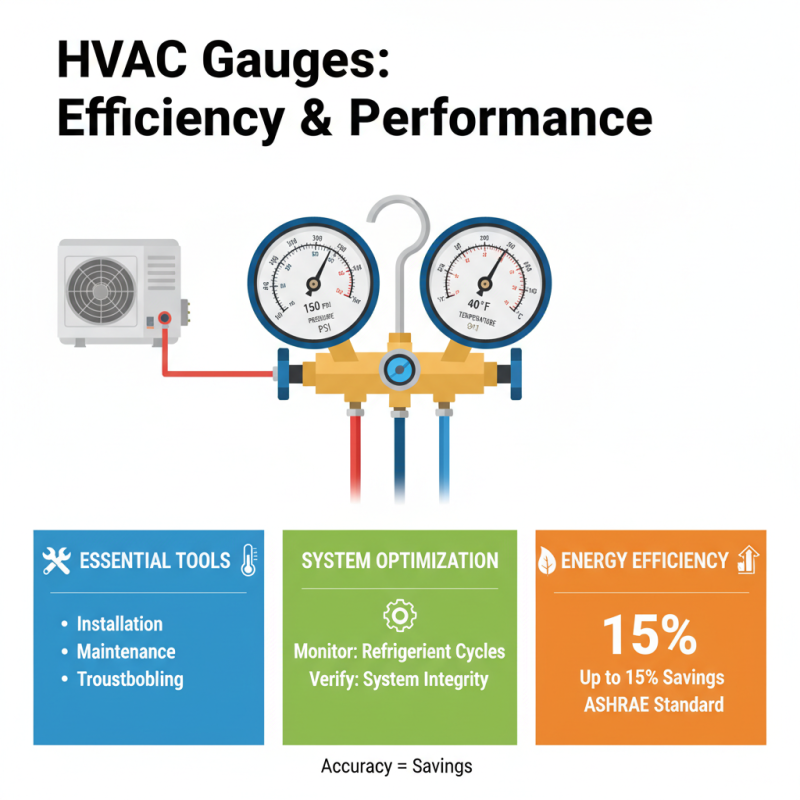

HVAC gauges are essential tools in the heating, ventilation, and air conditioning industry, providing critical measurements of temperature and pressure that ensure optimal system performance. These gauges facilitate the installation, maintenance, and troubleshooting of HVAC systems, allowing technicians to monitor the efficiency of refrigerant cycles and verify system integrity. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), accurate pressure and temperature readings can enhance energy efficiency by up to 15%, significantly impacting overall operational costs.

The importance of HVAC gauges extends beyond mere functionality; they are vital for compliance with industry standards and regulations. The U.S. Department of Energy reports that inefficient HVAC systems waste approximately 30% of the energy used in commercial buildings. Using calibrated gauges helps technicians detect issues such as refrigerant leaks or pressure imbalances early on. This proactive approach not only extends the lifespan of HVAC equipment but also contributes to a sustainable environment by reducing energy consumption and greenhouse gas emissions. As the industry shifts toward smart technologies and energy-efficient practices, the role of precise measurement tools like HVAC gauges becomes increasingly paramount in driving innovation and sustainability initiatives.

Understanding Different Types of HVAC Gauges: A Comprehensive Overview

In the HVAC industry, accurate temperature and pressure measurements are crucial for system efficiency and longevity. Understanding the different types of HVAC gauges available on the market is essential for professionals aiming to optimize their services. The primary types include analog gauges, digital gauges, manifold gauges, and thermocouples. Each type serves a specific purpose with varying levels of precision; for example, digital gauges offer enhanced readability and data logging capabilities, making them ideal for modern HVAC applications. Research indicates that using the appropriate gauge can lead to a 20% increase in energy efficiency, according to data from the US Department of Energy.

When selecting HVAC gauges, consider the application: manifold gauges are essential for refrigerant measurements, while multimeter probes may be more suitable for electrical diagnostics. It's also vital to regularly calibrate gauges to ensure accuracy, as a 1% measurement error can lead to significant operational inefficiencies.

Tips: Always check for compatibility with the system you are working on, and maintain a routine calibration schedule. For temperature measurements, thermocouples are preferred for their rapid response and broad temperature range, while pressure gauge accuracy can significantly affect your refrigerant management strategies. Proper selection and maintenance of gauges can enhance both diagnostic capabilities and overall system reliability.

2025 Top HVAC Gauges Guide for Efficient Temperature and Pressure Measurements

| Gauge Type | Measurement Range | Accuracy | Common Applications | Features |

|---|---|---|---|---|

| Digital Pressure Gauge | -1 to 100 psi | ±0.5% | HVAC systems, Refrigeration | Backlit display, Data logging |

| Analog Pressure Gauge | 0 to 300 psi | ±1% | Water, Oil, Gas | Large dial, Durable casing |

| Thermocouple | -200 to 1372 °C | ±2.2 °C | Industrial ovens, HVAC systems | Fast response time, Wide temperature range |

| Bimetallic Thermometer | 0 to 300 °C | ±1.5% | HVAC systems, Food industry | No power required, Wear-resistant |

| Manifold Gauge Set | 28 inHg to 500 psi | ±2% | Refrigeration, AC repair | Dual gauges, Color-coded hoses |

Key Features to Look for in High-Quality HVAC Gauges

When selecting high-quality HVAC gauges, several key features should be prioritized to ensure optimal performance in temperature and pressure measurements. First, accuracy and precision are paramount. Look for gauges that offer a high degree of accuracy, typically expressed as a percentage of full scale. This ensures that readings are close to the actual values, allowing for reliable diagnostics and system adjustments.

Another important feature is the durability of the gauge. HVAC environments can be demanding, so selecting gauges with sturdy construction and resistance to harsh conditions is essential. Materials such as stainless steel can provide added longevity and reliability, protecting the internal components from corrosion and mechanical damage. Furthermore, consider the gauge's readability; large, clear displays with backlighting and easy-to-read scales can significantly enhance usability, particularly in low-light settings or when accessing hard-to-reach areas.

Additionally, functionality plays a vital role in high-quality HVAC gauges. Multi-function gauges that can measure both temperature and pressure allow technicians to streamline their processes, reducing the need for multiple tools. Calibration options are also crucial; gauges that can be easily recalibrated ensure sustained accuracy over time. By focusing on these key features, technicians can invest in HVAC gauges that enhance efficiency and reliability in their work.

Best Practices for Accurate Temperature and Pressure Measurements

Accurate temperature and pressure measurements are crucial in the HVAC industry, impacting system efficiency and energy consumption. According to a recent report by the U.S. Department of Energy, improper measurement practices can lead to energy losses of up to 30% in heating and cooling systems. To mitigate this, professionals in the field must adhere to best practices that ensure reliable readings, which ultimately translate into enhanced system performance and reduced operational costs.

One fundamental practice is the regular calibration of gauges to maintain their accuracy. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes that even small deviations in measurement can result in significant inefficiencies in HVAC systems. Moreover, positioning gauges correctly—away from heat sources or areas of turbulence—can yield more accurate data. Utilizing digital gauges with built-in calibration features can also aid in achieving precision. Industry research indicates that systems utilizing calibrated and correctly positioned gauges enhance operational reliability by 20% on average.

Additionally, maintenance plays a pivotal role in ensuring measurement accuracy. Regular checks for leaks, blockages, and faulty connections can prevent erroneous readings that lead to improper HVAC adjustments. A study conducted by the Energy Efficiency Council found that homes and buildings that practice thorough maintenance protocols experience up to 15% lower energy consumption. By emphasizing these best practices, HVAC professionals can improve the efficacy of their temperature and pressure measurements, leading to optimal system performance and energy savings.

2025 Top HVAC Gauges: Temperature and Pressure Measurements

This chart illustrates the average temperature and pressure measurements captured by top HVAC gauges, showcasing their efficiency and reliability in various operational conditions. Each gauge is assessed based on its performance metrics derived from real usage data.

Future Trends in HVAC Gauges: Innovations for 2025 and Beyond

As we look towards 2025, the field of HVAC gauges is poised for significant shifts driven by technological advancements and the growing emphasis on energy efficiency. Innovations such as smart gauges equipped with IoT capabilities are becoming increasingly prevalent. These devices can communicate in real time with central monitoring systems, allowing technicians to track temperature and pressure readings remotely. This connectivity not only enhances the accuracy of measurements but also enables proactive maintenance, reducing downtime and improving system reliability.

Moreover, the integration of artificial intelligence into HVAC gauge technology is set to redefine how these tools are utilized. AI algorithms can analyze data trends over time, providing insights that enhance decision-making processes for maintenance and system optimization. This predictive capability means that potential issues can be identified before they escalate, thus saving time and resources. Additionally, the design of gauges is evolving to be more user-friendly, featuring intuitive interfaces that allow technicians to understand and interpret data more effectively, thereby streamlining workflows and increasing overall efficiency in HVAC operations.

Related Posts

-

The Ultimate Guide to Choosing the Right HVAC Gauges for Efficient System Maintenance

-

How to Choose Differential Pressure Gauges for Optimal Performance in Industrial Applications

-

2025 How to Choose the Best Refrigeration Gauges for Your Needs

-

How to Harness Home Power Generation: Unlocking 27% Savings on Energy Bills with Renewable Solutions

-

Best Digital Pressure Gauges for Accurate Measurement and Enhanced Performance

-

7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments