Top 5 HVAC Pressure Gauges for Accurate Readings and Reliable Performance

In the world of heating, ventilation, and air conditioning (HVAC) systems, precision and reliability are paramount. One of the essential tools for HVAC professionals is the HVAC pressure gauge. These instruments are crucial for measuring pressure levels within the system, ensuring that each component operates efficiently and effectively. With the increasing demand for energy-efficient solutions and optimal system performance, having accurate readings from HVAC pressure gauges can lead to significant improvements in diagnostics, maintenance, and overall service quality.

Choosing the right HVAC pressure gauges can make a difference in troubleshooting and optimizing HVAC systems. From digital displays that provide clear readings to analog gauges for simplicity and durability, the options available cater to various needs and preferences. Understanding the features and specifications of these gauges allows HVAC technicians to select the most suitable tools for their specific applications, resulting in enhanced performance and reduced downtime.

In the following sections, we will explore the top five HVAC pressure gauges that stand out for their accuracy and reliability. By focusing on these high-quality instruments, HVAC professionals can ensure that they are equipped with the best tools to maintain and service their systems, ultimately leading to better outcomes for both clients and contractors in the industry.

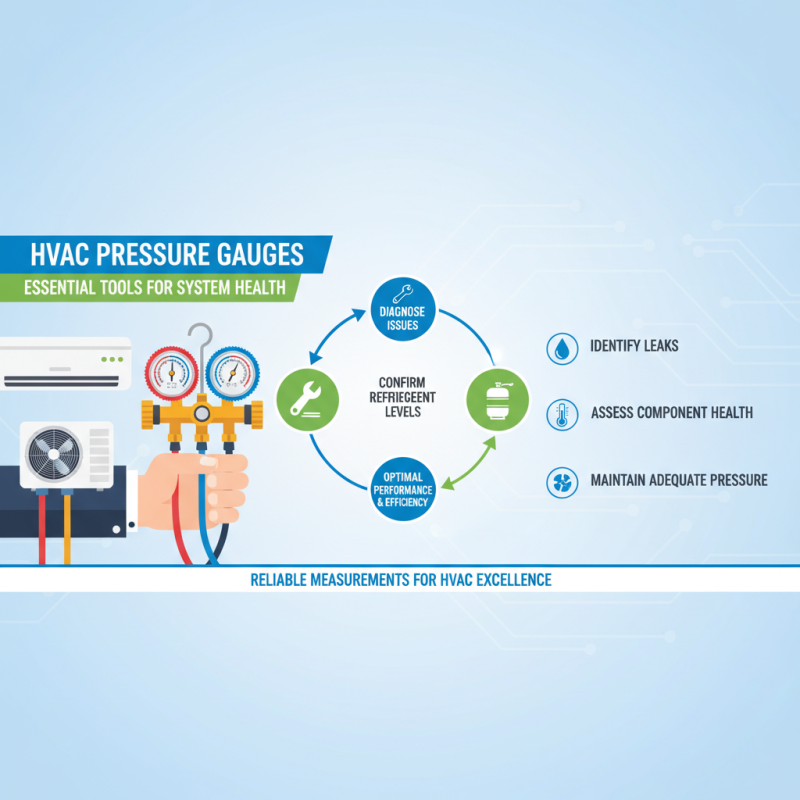

Understanding HVAC Pressure Gauges and Their Importance

HVAC pressure gauges are essential tools in the fields of heating, ventilation, and air conditioning. They provide accurate readings of pressure levels within HVAC systems, which is crucial for ensuring optimal performance and efficiency. Understanding the function and importance of these gauges helps technicians diagnose system issues and maintain adequate pressure settings. With reliable measurements, they can identify leaks, confirm proper refrigerant levels, and assess the health of various components throughout the system.

Accurate pressure readings can significantly impact the longevity and efficiency of HVAC systems. By regularly monitoring pressure, technicians can detect potential problems before they escalate, thus minimizing downtime and costly repairs. Moreover, maintaining the correct pressure balances ensures energy efficiency, leading to lower operating costs and reduced environmental impact. In summary, HVAC pressure gauges are vital for both the functionality and sustainability of heating and cooling systems, making them an indispensable tool for any HVAC professional.

Key Features to Consider When Selecting a Pressure Gauge

When selecting a pressure gauge for HVAC systems, several key features should be prioritized to ensure accurate readings and reliable performance. Firstly, the range of the gauge is crucial; it must accommodate the typical pressures encountered in HVAC applications. Gauges with a wide range allow for more versatility across different systems, while those with limited ranges may not provide accurate readings if pressures fluctuate outside their specified limits.

Another important feature is the type of display. Digital gauges offer easy-to-read measurements and often come with additional functionalities like data logging and alerts for abnormal readings. Meanwhile, analog gauges, while sometimes more affordable, rely on mechanical components which can wear down over time. It's also vital to consider the material and construction of the gauge; durable materials can withstand harsh conditions, enhancing longevity and maintaining accuracy in demanding environments. Features such as anti-vibration mechanisms or weatherproof casings can greatly enhance the reliability and lifespan of the instrument.

In addition to these features, user-friendliness should not be overlooked. A gauge that is easy to calibrate and maintain will save time and effort in the long run. Look for gauges with clear markings and intuitive designs that facilitate quick and accurate readings, ensuring that HVAC technicians can diagnose and address issues efficiently.

Top 5 HVAC Pressure Gauges for Accurate Readings and Reliable Performance

| Gauge Model | Pressure Range | Display Type | Connection Type | Key Feature |

|---|---|---|---|---|

| Gauge A | 0-150 PSI | Analog | 1/4" NPT | Dual Scale |

| Gauge B | 0-300 PSI | Digital | 1/4" NPT | Backlit Display |

| Gauge C | 0-500 PSI | Analog | 1/2" NPT | Shockproof |

| Gauge D | 0-1000 PSI | Digital | 1/4" NPT | Wireless Data Transfer |

| Gauge E | 0-200 PSI | Analog | 1/4" NPT | Easy Calibration |

Top 5 Recommended HVAC Pressure Gauges for 2023

When it comes to selecting HVAC pressure gauges for 2023, accuracy and reliability are paramount. Technicians and HVAC professionals require tools that provide precise readings to ensure systems operate efficiently. These gauges are critical not only for diagnosing issues but also for routine maintenance checks. The ideal HVAC pressure gauge should feature clear markings, a robust design, and an easy-to-read display, which contributes significantly to their reliability during use.

In this year's top recommendations, we see a blend of features that cater specifically to industry needs. Some gauges boast advanced technology, including digital displays that facilitate quick readings and lower error margins. Others maintain a traditional analog approach, which many professionals still prefer for its simplicity and durability. Regardless of the preference for analog or digital, each gauge stands out due to its ability to withstand harsh environmental conditions, ensuring prolonged service life. Thus, HVAC professionals can confidently choose from these top-rated options, knowing they will deliver consistent performance throughout the year.

Comparison of Accuracy and Performance Among Different Models

When selecting HVAC pressure gauges, accuracy and performance are paramount. A comparative analysis among different models reveals that precision can vary significantly, impacting system efficiency and safety. According to industry standards, readings within ±1% of full scale are essential for optimal HVAC operation. Pressure gauges that maintain this level of accuracy ensure that technicians can diagnose system issues effectively and achieve the desired performance metrics.

It's crucial to consider the gauge's build quality and responsiveness, as these factors directly affect performance. Digital gauges, for example, tend to provide faster readings and clearer displays compared to analog counterparts, making them preferable for real-time monitoring. Reports from industry professionals highlight that the adoption of digital gauges has increased in recent years, correlating with enhanced accuracy and user efficiency. Regular calibration checks have also become a standard best practice, ensuring that readings remain consistent and reliable over time.

Tips: Always review the specifications of pressure gauges before purchasing, focusing on accuracy ratings and response time. Additionally, investing time in proper calibration techniques can significantly enhance the lifespan and reliability of your equipment. Finally, consider the environmental conditions where the gauge will be used, as extreme temperatures or humidity can affect performance.

Maintenance Tips for Ensuring Longevity of Pressure Gauges

Maintaining the accuracy and reliability of HVAC pressure gauges is essential for optimal performance in heating, ventilation, and air conditioning systems. To ensure the longevity of these instruments, regular cleaning is crucial. Dust and debris can accumulate over time, affecting the internal mechanisms. Using a soft cloth and non-abrasive cleaning agents, you can gently wipe the exterior while avoiding any damage to sensitive components. Furthermore, it is important to keep the gauges away from extreme temperatures and humidity, as these conditions can compromise their functionality.

Another vital maintenance tip is to routinely check and calibrate the gauges. Even the most sophisticated instruments can drift over time, leading to inaccurate readings that can impact system efficiency. By periodically comparing the gauge readings against a known standard, you can identify any deviations and recalibrate accordingly. Additionally, monitoring for any signs of wear, such as cracks or leaks around the connections, can prevent larger issues from developing. Ensuring proper installation with secure fittings also contributes to the durability of pressure gauges, allowing them to consistently deliver precise measurements essential for HVAC system maintenance.

Top 5 HVAC Pressure Gauges for Accurate Readings

This chart represents the accuracy performance of the top 5 HVAC pressure gauges based on user feedback and testing data. The gauges are evaluated based on their pressure measurement range and accuracy percentage.

Related Posts

-

7 Essential Tips for Choosing the Right Marsh Pressure Gauges for Your Needs

-

Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

-

2025 Top 5 Differential Pressure Measurement Solutions You Should Know

-

Understanding the Science Behind Liquid Filled Gauges and Their Essential Role in Industries

-

How to Choose Precision Instruments for Optimal Measurement Accuracy: A Data-Driven Guide

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments