Top 10 Marsh Pressure Gauges You Need to Know?

Marsh pressure gauges are essential tools in various industries. These gauges provide accurate pressure readings that ensure safety and efficiency in operations. According to a recent industry report, the demand for pressure measuring devices, including marsh pressure gauges, is projected to grow by 5% annually. This highlights their importance in both manufacturing and process industries.

Understanding the top marsh pressure gauges is crucial for professionals. The right gauge can make a significant difference in performance and reliability. In sectors like oil and gas, even minor inaccuracies can lead to costly downtimes or safety hazards. A study indicated that improper pressure monitoring can increase operational costs by up to 20%. This underscores the need to select the best tools available.

Choosing the right marsh pressure gauge can be overwhelming. With various models and brands on the market, how do you make the best choice? Professionals often struggle with this decision. Mistakes in gauge selection can lead to serious consequences. It is vital to assess both quality and application to ensure the highest standards of precision and safety.

Understanding Marsh Pressure Gauges: An Overview

Marsh pressure gauges are essential tools in various industries. They measure pressure accurately, ensuring safety and efficiency. Understanding how these gauges work is crucial for any technician or engineer. These devices consist of a diaphragm that reacts to pressure changes. As pressure increases, the diaphragm flexes, which indicates readings on the gauge.

Proper calibration is vital for accurate results. A well-calibrated gauge ensures that operations run smoothly. Conversely, a poorly calibrated gauge can cause catastrophic failures. Regular maintenance is also needed. Without it, the gauges can become less responsive. This may lead to misleading readings and safety hazards.

Many users find themselves unsure about which gauge to choose. The market offers a range of models, and features vary widely. It's easy to feel overwhelmed by options. Not all gauges will suit every application. Identifying the right type for your needs requires careful consideration. Reflecting on past choices may prevent future mistakes.

Key Features to Look for in Marsh Pressure Gauges

When selecting Marsh pressure gauges, pay attention to several key features. Accuracy is paramount. Look for gauges with a proven accuracy of ±1% of full scale. This ensures reliable readings in critical applications. Additionally, consider the range of pressure that the gauge can measure. A wide range allows flexibility in various industries.

Material selection also plays a crucial role. Many gauges use stainless steel for durability and resistance to corrosion. This is essential in harsh environments. Some gauges feature advanced diaphragm seals, which enhance their lifespan and reliability.

Tip: Regular calibration can extend the life of your pressure gauge. Check accuracy every six months to ensure consistent performance.

Another vital feature is the gauge's readability. Larger, clear dials with marked increments improve usability in dynamic settings. Some include backlighting for low-light conditions. While these features add convenience, they can also introduce complexity. Ensure operators are trained to interpret the readings accurately.

Tip: Investing in training reduces misinterpretation. A well-informed team leads to better decision-making. Many companies see a 30% reduction in errors after proper training.

Incorporating these elements will enhance the effectiveness of your Marsh pressure gauge selection. Your choice should balance durability, accuracy, and user-friendliness tailored to your operational needs.

Top 10 Recommended Marsh Pressure Gauges for Various Applications

When selecting a pressure gauge, variety matters. Different applications demand different specifications. For instance, some gauges are better suited for HVAC systems, while others excel in water treatment facilities. A gauge’s capacity can vary widely. Knowing your application's pressure range helps to inform your choice.

There are gauges that offer analog displays. These can provide immediate readings. Digital gauges offer precision. The choice between analog and digital often depends on user preference. Consider ease of reading. Some may find analog gauges harder to interpret quickly. Others trust digital readings for accuracy.

Durability is another essential factor. Heavy industrial use requires robust materials. Look for gauges that can withstand harsh environments. High humidity or temperature fluctuations could affect readings. Inconsistent pressure measurements may lead to problems. Paying attention to details can prevent headaches down the line. Finding a suitable gauge is vital for optimal performance in any application.

How to Properly Install and Maintain Marsh Pressure Gauges

Installing and maintaining pressure gauges requires careful attention. Proper installation is vital for accurate readings.

Begin by selecting an appropriate location for the gauge. Ensure it is accessible for future checks. Clear any obstructions. Use appropriate fittings to connect the gauge to the pressure source.

Avoid over-tightening, as it may damage the gauge.

Maintenance is equally crucial for longevity. Regularly inspect the gauge for signs of wear. Look for leaks or corrosion.

These can affect performance. Clean the gauge casing periodically. Dust and grime can accumulate, impacting visibility. Calibration should occur as needed.

Make a habit of checking the gauge against a known standard.

Mistakes can happen. Sometimes installation is rushed, leading to misalignment. This can cause inaccurate readings.

Skipping maintenance may seem easier, but it leads to bigger issues down the line. Always have a plan for routine checks.

This will keep your pressure gauges functioning effectively. Failure to do so can result in costly repairs and downtime. Stay vigilant.

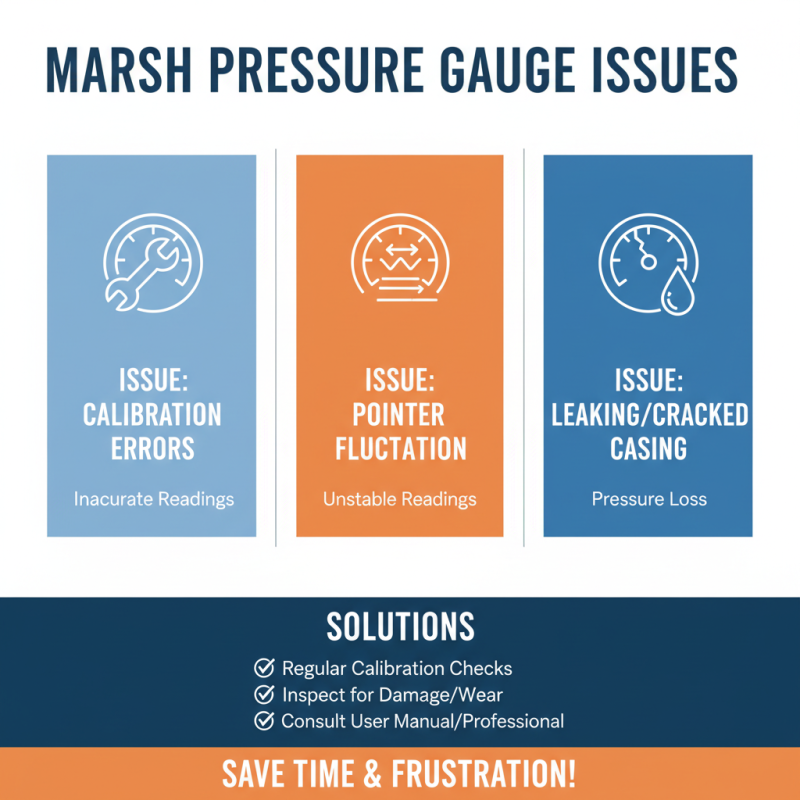

Common Issues and Troubleshooting Tips for Marsh Pressure Gauges

When using Marsh pressure gauges, common issues may arise. Understanding these can save time and frustration. Calibration errors often lead to inaccurate readings. Make sure to check the calibration regularly. A simple test can reveal if the gauge is working correctly.

Leaking connections are another concern. This can cause fluctuations in pressure readings. Inspect the fittings and hoses frequently. Tighten any loose connections. Sometimes, a small amount of leakage can lead to larger problems. Keep an eye out for any signs of wear and tear.

Another frequent issue is condensation within the gauge. Moisture can affect the internal mechanisms. Use moisture traps or dryers to prevent this. Regularly monitor for any changes in gauge performance. A proactive approach is essential. Addressing these issues promptly can enhance the longevity of your gauge.

Related Posts

-

7 Surprising Benefits of Liquid Filled Pressure Gauges for Your Industry

-

What are Marsh Pressure Gauges and Their Critical Role in Industrial Applications?

-

How to Optimize Your System Using Differential Pressure Measurements

-

The Essential Guide to Understanding Pressure Gauges: Applications, Types, and Maintenance Tips

-

How to Choose the Right Pressure Gauges for Your Applications

-

Top Types of Pressure Gauges for Accurate Measurement in Various Applications

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments