The Ultimate Guide to Choosing Digital Gauges for HVAC Systems

In the ever-evolving landscape of HVAC technology, the selection of appropriate tools can significantly impact system performance and maintenance. Among these tools, digital gauges HVAC stand out as essential instruments that provide accurate measurements and facilitate efficient system diagnostics. As HVAC professionals and enthusiasts alike seek to optimize their systems, understanding the nuances of choosing the right digital gauges becomes increasingly important.

This comprehensive guide aims to equip readers with the knowledge necessary to make informed decisions when selecting digital gauges for HVAC applications. We will explore the features to look for, the types of digital gauges available, and the benefits they offer compared to their analog counterparts. By the end of this guide, readers will have a clear framework for evaluating their options, ensuring that the tools they select not only meet their immediate needs but also enhance the overall performance and longevity of HVAC systems.

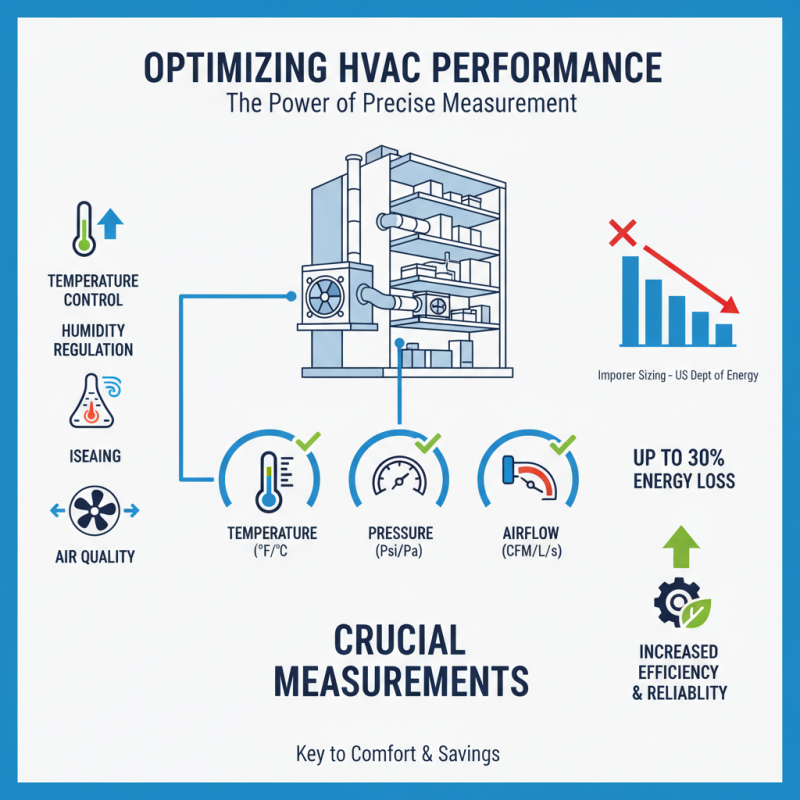

Understanding HVAC Systems and Their Measurement Needs

When considering HVAC systems, understanding their measurement needs is crucial for optimizing performance and ensuring efficiency. HVAC systems are designed to control the temperature, humidity, and air quality in indoor environments. Accurate measurements of parameters such as temperature, pressure, and airflow are essential to maintain the reliability and effectiveness of these systems. According to the U.S. Department of Energy, improper HVAC system sizing can lead to energy inefficiencies of up to 30%, highlighting the importance of precise measurements in the design and operation of these systems.

Digital gauges play a vital role in achieving accurate measurements for HVAC applications. They provide real-time data that technicians can use to diagnose issues quickly and monitor system performance effectively. In fact, a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that using advanced measurement tools can improve energy efficiency by 15-25%. By integrating digital gauges into their workflow, HVAC professionals can better understand their systems' operational parameters, leading to enhanced system reliability and reduced energy costs. These advancements in measurement technology not only enhance system performance but also promote sustainable practices within the industry.

Types of Digital Gauges Used in HVAC Applications

When it comes to HVAC systems, the precision and reliability of measurements directly impact system efficiency and performance. Various types of digital gauges are utilized to monitor vital parameters, ensuring optimal operation. Primarily, pressure gauges, temperature gauges, and multimeters play crucial roles in HVAC applications. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), maintaining appropriate pressure and temperature levels can lead to a significant increase in energy efficiency, potentially reducing operational costs by up to 20%.

Digital pressure gauges provide real-time data on refrigerant pressures, vital for diagnosing system issues. They feature high accuracy and can often relay data wirelessly, enhancing monitoring convenience. Temperature gauges, on the other hand, are essential for assessing air temperature throughout various components of the HVAC system. In a study published by the International Journal of HVAC, it was noted that accurate temperature readings are critical in maintaining indoor air quality and energy conservation.

Multimeters are indispensable in HVAC troubleshooting, capable of measuring voltage, current, and resistance. Their versatility allows technicians to diagnose a wide range of electrical and electronic issues that may arise within HVAC systems. Reports show that proper electrical diagnostics can prevent potential system failures and extend the lifespan of HVAC equipment, emphasizing the importance of integrating reliable digital gauges in HVAC maintenance protocols.

Key Features to Consider When Choosing Digital Gauges

When selecting digital gauges for HVAC systems, there are several key features that should be considered to ensure optimal performance and accuracy. Firstly, the gauge's measurement range is crucial; it must cover the specific pressure and temperature ranges encountered in HVAC applications. A gauge with a broader range allows for versatile use across different systems, minimizing the need for multiple instruments. Additionally, accuracy and resolution are essential; high-resolution gauges provide more precise readings, which is vital for troubleshooting and monitoring system performance.

Another important feature to consider is the display type and size. A clear, backlit display enhances visibility and makes it easier to read measurements in various lighting conditions. User-friendly interfaces, with simple navigation and data logging capabilities, can significantly improve the efficiency of HVAC professionals in the field. Furthermore, the durability of the gauge should not be overlooked. Look for models with rugged construction that can withstand harsh working environments without compromising functionality. These features collectively ensure that the digital gauge not only meets operational needs but also enhances the efficiency and reliability of HVAC system maintenance and diagnostics.

Installation and Calibration of Digital Gauges in HVAC Systems

When it comes to HVAC systems, the accurate installation and calibration of digital gauges are crucial for optimal performance and efficiency. Before installation, ensure that the area where the gauges will be placed is clean and unobstructed to avoid any inaccuracies during measurement. It's essential to follow the manufacturer’s manual for specific guidelines, as each gauge may have unique requirements. Begin by securely mounting the gauges in a suitable location, typically near the service access points, to facilitate ease of use and readability. Proper wiring and connection to the HVAC system, whether for pressure or temperature measurement, will ensure that the gauges function as intended.

Calibration of digital gauges is just as important as their installation. After installation, it’s vital to calibrate the gauges to guarantee accurate readings. This usually involves comparing the gauge readings with a known reference standard. If discrepancies are found, adjustments must be made according to the manufacturer’s specifications. Regular calibration checks are recommended to maintain accuracy, especially in systems that undergo frequent changes in operational conditions. By prioritizing precise installation and diligent calibration, HVAC technicians can enhance the reliability of their systems, ultimately leading to improved energy efficiency and reduced operational costs.

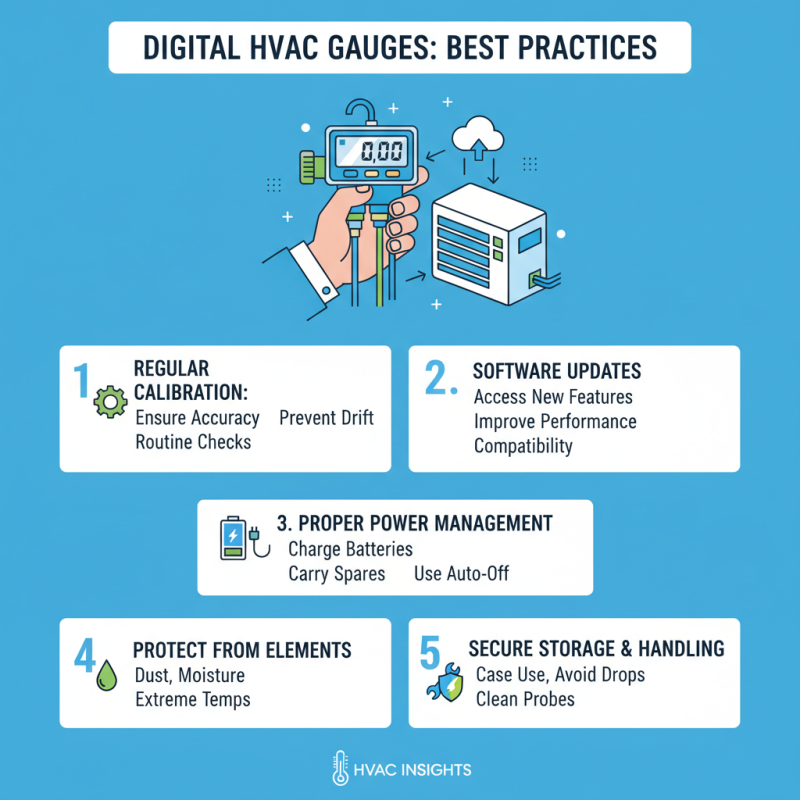

Best Practices for Maintaining and Using Digital Gauges

Maintaining and using digital gauges for HVAC systems effectively requires attention to several key best practices. First and foremost, regular calibration is essential to ensure accuracy. Over time, gauges can drift from their calibrated settings due to environmental factors or normal wear and tear. Therefore, HVAC professionals should routinely check and calibrate their digital gauges to provide reliable readings during system diagnostics and performance evaluations.

Another critical aspect is proper handling and storage of the gauges. Digital gauges should be kept in protective cases when not in use to prevent physical damage and exposure to extreme temperatures or humidity, which can affect their functionality. When using the gauges, it’s important to follow the manufacturer's instructions and avoid subjecting them to conditions outside their specified operating ranges. Furthermore, training and familiarizing oneself with the specific features and functions of the digital gauge can enhance performance and decision-making during HVAC maintenance and troubleshooting tasks. By adhering to these best practices, technicians can ensure the longevity and effectiveness of their digital gauges, leading to improved HVAC system performance and reliability.

Related Posts

-

Top Strategies for Utilizing Digital Gauges in HVAC Efficiency

-

What Are Digital Gauges and How Do They Revolutionize Modern Measurement?

-

Exploring the Future of Digital Gauges at the 138th Canton Fair in 2025

-

10 Essential Tips for Choosing the Right Digital Gauges for Your Needs

-

What are Digital Gauges for HVAC and How Do They Improve Efficiency

-

7 Essential Reasons to Choose the Right Instruments and Gauges for Your Industry

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments