Understanding Differential Pressure: Key Concepts and Applications Explained

In the realm of fluid mechanics and process engineering, understanding differential pressure is crucial for a myriad of applications, from industrial processes to environmental monitoring. As industry expert Dr. Emily Carter states, "The accurate measurement and control of differential pressure not only ensure operational efficiency but also play a vital role in maintaining safety and compliance across various sectors." This highlights the significance of differential pressure in modern engineering practices.

Differential pressure serves as a fundamental concept that governs how fluids move and interact within systems, impacting equipment performance and system reliability. By examining the pressure differences between two points in a system, engineers can gain insights into flow rates, filter conditions, and potential blockages. Moreover, the applications of differential pressure measurement extend beyond traditional settings, finding use in HVAC systems, biomedical devices, and even in the aerospace industry. Understanding these principles is essential not only for maintaining optimal operations but also for innovating solutions in an increasingly complex industrial landscape.

As we delve deeper into the key concepts and practical applications of differential pressure, we will explore its importance in engineering decision-making, troubleshooting techniques, and the advancement of technology. Grasping the intricacies of this phenomenon will empower professionals to make informed choices that enhance performance and safety across diverse fields.

Understanding the Definition of Differential Pressure in Fluid Dynamics

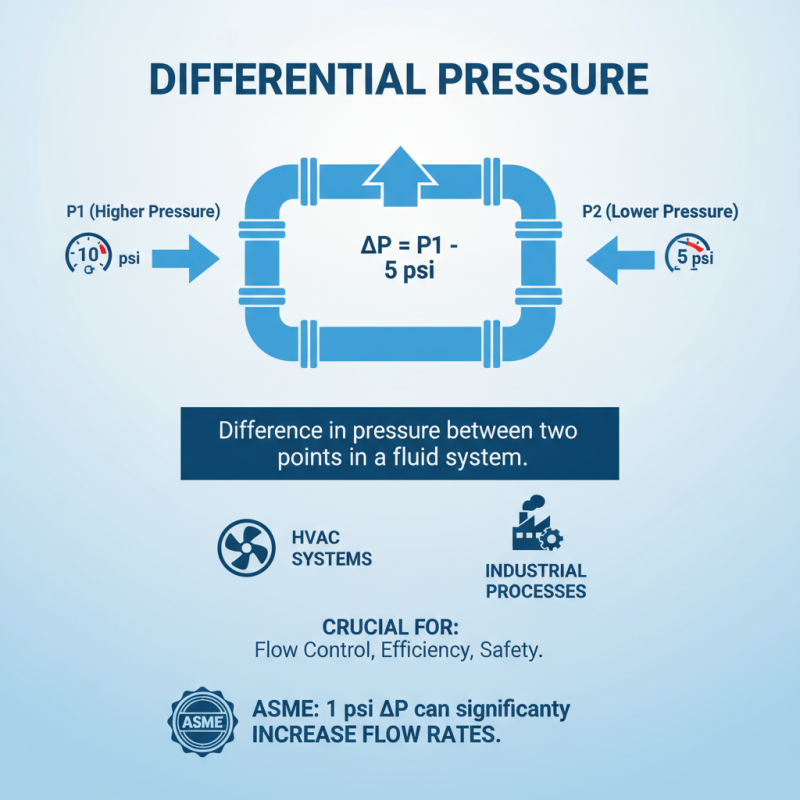

Differential pressure refers to the difference in pressure between two points in a fluid system, a fundamental concept in fluid dynamics. It plays a crucial role in various applications, including HVAC systems, process industry operations, and environmental monitoring. According to the American Society of Mechanical Engineers, a differential pressure of only 1 psi can lead to a significant increase in flow rates, thereby impacting efficiency and safety in industrial processes. Understanding this concept is vital for system design and maintenance, as it directly influences the performance and reliability of equipment.

Tips: When measuring differential pressure, it’s essential to use calibrated instruments to ensure accuracy. Inaccurate readings can lead to inefficient system performance, increased energy costs, and even hazardous situations.

In practical terms, differential pressure can indicate whether a filter is clogged or whether there are issues within a piping system. For instance, a study by the International Society of Automation found that monitoring differential pressure across filters can improve lifespan by up to 20%. By regularly checking these pressure values, operators can optimize maintenance schedules and avoid costly downtimes.

The Importance of Differential Pressure in Industrial Applications

Differential pressure is a critical measurement in various industrial applications, playing a vital role in monitoring and controlling processes. It refers to the difference in pressure between two points in a system, which can indicate flow rates, filter conditions, and leak detection. In many industries, such as oil and gas, pharmaceuticals, and water treatment, maintaining the correct differential pressure is essential to ensure operational efficiency and safety.

One of the primary applications of differential pressure is in the management of filtration systems. In this context, monitoring the pressure drop across a filter can help operators determine when a filter replacement is necessary, thereby preventing equipment damage and ensuring product quality. Similarly, in HVAC systems, maintaining the correct differential pressure across ducts and equipment ensures optimal air flow, energy efficiency, and indoor air quality. This underscores the importance of differential pressure in maximizing performance and minimizing operational costs across diverse industrial settings.

Understanding Differential Pressure in Industrial Applications

This bar chart illustrates the significance of differential pressure across various industrial applications. Each application shows different ranges of differential pressure (in Pascals) commonly encountered in real-world scenarios.

Key Measurement Techniques for Accurate Differential Pressure Readings

Differential pressure measurement is crucial in various applications, particularly in gas flow management and biomedical research. Accurate differential pressure readings facilitate the precise control of gas mixtures in laboratory settings, ensuring that experiments maintain the desired conditions. With advanced measurement techniques, researchers can achieve the necessary precision for low flow applications, allowing for better control over environmental variables.

One notable innovation is the introduction of a new differential pressure flowmeter designed to measure gases, liquids, and steam across a range of pipe sizes. This technological advancement streamlines processes in industries where accurate flow measurements are essential, including in oil/water separation and gas processing facilities. Additionally, the importance of effective measurement techniques is underscored in the context of blood pressure monitoring, where precise readings are vital for assessing cardiovascular risks. Incorporating innovative methods can significantly enhance the reliability and accuracy of differential pressure measurements in various fields.

Differential Pressure Sensors: Types and Selection Criteria

Differential pressure sensors play a crucial role in various industrial applications, providing accurate measurements essential for process control and monitoring. The market for these sensors is expected to grow significantly, driven by increasing demands for automation and precision in industries such as oil and gas, chemical manufacturing, and water treatment. According to industry reports, the market for pressure sensors is projected to reach USD 13.5 billion by 2025, with a notable shift towards advanced sensing methods like MEMS and optical technologies that enhance measurement accuracy and reliability.

When selecting a differential pressure sensor, it is essential to consider the type and sensing method based on the intended application. Piezoresistive and capacitive sensors are widely used for fluid flow applications due to their sensitivity and responsiveness to pressure changes. In contrast, resonant solid-state sensors offer high stability and accuracy, making them suitable for critical measurements in harsh environments. As industries continue to optimize processes, understanding the distinctions among these various types—absolute, gauge, and differential pressure sensors—ensures the right choice for precise flow measurement and efficient operation.

Analyzing Differential Pressure Data to Optimize System Performance

Differential pressure (DP) measurement is a critical tool in various industrial applications, particularly in optimizing system performance. By analyzing DP data, engineers can gain insights into the operational efficiency of systems such as HVAC, filtration, and process control. The difference in pressure between two points in a system helps identify blockages, leaks, or excessive flow restrictions that can affect overall performance. By regularly monitoring these values, operators can address issues before they escalate, leading to reduced downtime and maintenance costs.

Furthermore, understanding DP not only assists in troubleshooting but also in fine-tuning system operations. For instance, in HVAC systems, maintaining optimal differential pressure ensures effective airflow and energy efficiency. Adjustments based on DP readings can lead to significant savings in energy consumption, while also enhancing occupant comfort. Similarly, in filtration systems, monitoring DP helps maintain filter integrity and prolongs equipment life by preventing overloading or premature failure. Overall, rigorous analysis of differential pressure data empowers organizations to enhance performance, safety, and reliability across their operations.

Related Posts

-

Top Strategies for Maximizing Efficiency with Differential Pressure Solutions

-

How to Choose Differential Pressure Gauges for Optimal Performance in Industrial Applications

-

Navigating the Challenges of Precision Devices in Today's High Demand Markets

-

Top Strategies for Enhancing Efficiency with AC Gauges in the HVAC Industry

-

Exploring Diaphragm Seals at the 138th China Import and Export Fair in 2025

-

How to Optimize Your System Using Differential Pressure Measurements

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments